A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

What is the Impact Crusher for Sale

The impact crusher is a medium and fine crushing equipment that uses impact energy to crush materials. It has the remarkable characteristics of large crushing ratio, excellent finished product particle shape, simple structure and convenient operation. It is widely used in mining, building materials, highways, railways, water conservancy and chemical industries. It is particularly suitable for crushing medium-soft materials with a compressive strength not exceeding 350MPa, such as limestone, coal gangue, concrete blocks, construction waste, etc. It is an important equipment in the current machine-made sand and gravel production line.

The working principle of the impact crusher is: when the material enters the crushing chamber, it is impacted by the plate hammer on the high-speed rotating rotor and thrown to the impact device (impact plate), and then rebounds back to the crushing area and is hit again. After multiple impacts and crushing, the material of the required particle size is formed and discharged from the discharge port. The whole process realizes efficient and multi-stage crushing of the material, and the finished product particle shape is polyhedral, which helps to improve the bonding force and construction performance of the concrete.

In terms of structural design, the impact crusher is usually composed of a rotor, a plate hammer, an impact plate, a liner, a feed port, a discharge port, a frame and a transmission system. In order to improve the durability and reliability of the equipment, modern impact crushers generally use high-chromium alloy wear-resistant plate hammers, high-strength alloy liners and hydraulic opening devices, which effectively reduce the maintenance difficulty and use cost of the equipment. At the same time, by adjusting the gap between the impact plate and the rotor, the discharge particle size can be flexibly controlled to meet the requirements of different projects.

With the continuous advancement of industrial technology, impact crushers have also been significantly improved in terms of intelligence, energy saving and environmental protection. Some high-end models are equipped with automatic lubrication systems, fault monitoring devices and intelligent control systems, which not only improve the safety and continuity of equipment operation, but also improve the overall production efficiency. In addition, its closed structure design and dust removal configuration help reduce dust pollution and meet green environmental protection production standards.

Impact crusher is a mature and widely used high-efficiency crushing equipment, especially suitable for medium and fine crushing operations with high requirements for particle shape. In modern production lines such as machine-made sand, building aggregates, and resource recycling, impact crushers have become an important choice for improving crushing efficiency and finished product quality with their excellent comprehensive performance and economy.

Operating principle of Impact Crusher for Sale

The impact crusher is a medium and fine crushing equipment that relies on impact energy to crush materials. Its working principle mainly revolves around the high-speed rotating rotor and the fixed impact plate. The working process of this equipment mainly includes multiple links such as feeding, impact crushing, rebound crushing and discharging. It has the advantages of reasonable structure, low energy consumption and good finished product particle shape. It is an important equipment commonly used in the field of modern sand and gravel aggregate production and resource recycling.

During operation, the material enters the crushing chamber from the feed port and quickly contacts the high-speed rotating rotor. The rotor is equipped with multiple plate hammers made of high-chromium alloy or other wear-resistant materials. These plate hammers will hit the material at a very high linear speed during high-speed rotation, and the material will be thrown to the impact plate on the inner wall of the machine body. After the first impact, some of the material is crushed, and others will rebound back to the crushing area and contact the rotor again for a second impact. In this cycle, the material is gradually broken into small particles during multiple impacts, rebounds, shearing and extrusion.

The crushing chamber of the impact crusher is usually designed with two or three impact plates. This structure allows the material to hit multiple times and be evenly distributed in the crushing area, thereby improving the crushing efficiency and obtaining a finished product with better particle shape. By adjusting the gap between the impact plate and the rotor, the operator can control the final particle size of the material and achieve crushing operations with different fineness requirements.

The open rotor structure adopted by the impact crusher helps to speed up the passage of materials, reduce the risk of blockage, and increase production capacity. Some equipment is also equipped with a hydraulic opening device, which makes the adjustment and maintenance of the spacing between the rotor and the impact plate more convenient, greatly improving the maintenance efficiency and safety.

The working principle of the impact crusher fully reflects the efficient design idea of "impact crushing + multi-stage crushing". The material continues to become smaller and the shape tends to be regular during the repeated impact, so as to obtain a finished product with excellent particle shape and reasonable grading. Due to its high efficiency, energy saving and simple structure, the impact crusher is not only widely used in the traditional quarrying industry, but also shows strong adaptability and application prospects in emerging fields such as urban construction waste recycling and renewable resource utilization.

Advantages and features of Impact Crusher for Sale

As an important crushing equipment widely used in modern mining and construction industries, impact crusher has many significant characteristics and advantages, meeting the needs of efficient, energy-saving and environmentally friendly crushing under different working conditions. First of all, the impact crusher uses a high-speed rotating rotor to throw the material to the impact plate, and uses the impact force to achieve crushing. This crushing method enables the equipment to have the advantages of large crushing ratio and high production efficiency. After multiple impact crushing, the finished product particle shape is polyhedral, the particles are uniform and the gradation is reasonable, which is particularly suitable for the production of machine-made sand and high-quality aggregates.

The impact crusher has a reasonable structural design, and key components such as plate hammers and impact plates are made of high-wear-resistant materials, which significantly improves the service life and wear resistance of the equipment and reduces maintenance costs. The application of the hydraulic opening system makes equipment maintenance more convenient and quick, greatly shortens downtime, and improves the availability of equipment. In addition, the overall structure of the equipment is compact, small in size, occupies less space, is easy to install and move, and has strong adaptability.

The impact crusher performs outstandingly in energy saving and environmental protection. Its optimized crushing chamber design and efficient power transmission system reduce energy consumption. At the same time, it is equipped with dust removal devices to reduce dust pollution in the production process, which meets the requirements of modern green mines and environmental protection. Some advanced models also integrate intelligent monitoring systems to achieve real-time monitoring of the equipment's operating status and fault warning, improving the safety and stability of operation.

Impact crusher has the advantages of easy operation and high degree of automation. By adjusting the gap between the impact plate and the rotor, the particle size of the discharge can be flexibly controlled to meet different production needs. The equipment has a wide range of applications and can handle a variety of materials such as limestone, granite, basalt, coal, and construction waste. It is particularly suitable for the recycling of construction waste and the utilization of renewable resources, which helps to promote resource recycling and sustainable development.

With its multiple advantages such as efficient crushing, excellent particle shape, strong durability, energy saving and environmental protection, and intelligent management, the impact crusher has become an important equipment choice for machine-made sand and gravel production and mine crushing. In the ever-evolving mining and construction markets, the impact crusher continues to meet users' needs for high-quality aggregates and efficient production with its excellent performance and reliable quality, and promotes technological progress and green development in the industry.

Technical Parameter Table of Impact Crusher for Sale

| Specification | Unit | Model A | Model B | Model C | Model D | Model E |

|---|---|---|---|---|---|---|

| Rotor Size (Diameter × Width) | mm | 900 × 800 | 1100 × 1000 | 1200 × 1300 | 1300 × 1400 | 1500 × 1600 |

| Maximum Feed Size | mm | ≤ 200 | ≤ 250 | ≤ 300 | ≤ 350 | ≤ 400 |

| Discharge Size Range | mm | 0–50 | 0–60 | 0–70 | 0–80 | 0–90 |

| Capacity | t/h | 50–100 | 100–150 | 150–200 | 200–300 | 300–400 |

| Motor Power | kW | 90 | 132 | 160 | 200 | 250 |

| Rotor Speed | r/min | 1000–1200 | 900–1100 | 850–1000 | 750–950 | 700–900 |

| Number of Hammers | pcs | 3 | 4 | 4 | 4 | 4 |

| Total Weight | t | 8 | 12 | 16 | 20 | 25 |

| Dimensions (L×W×H) | mm | 2200×1800×1700 | 2500×2200×2100 | 2800×2400×2300 | 3000×2600×2500 | 3500×2800×2700 |

| Applications | - | Limestone, Coal | Granite, Basalt | Aggregates, Ore | Concrete Waste | Mining, Cement |

If you have any special requirements, we will customize according to your special needs.

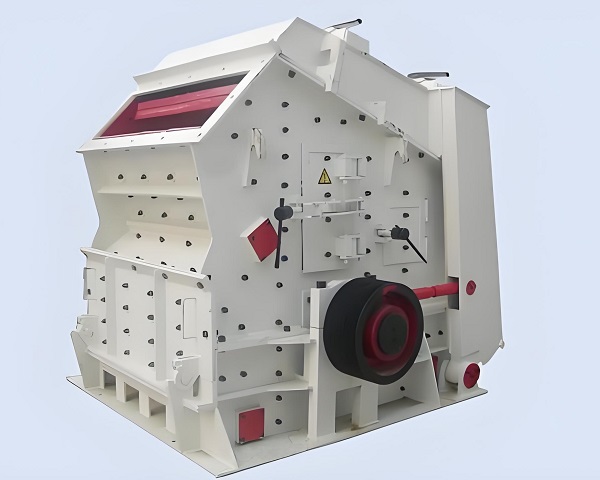

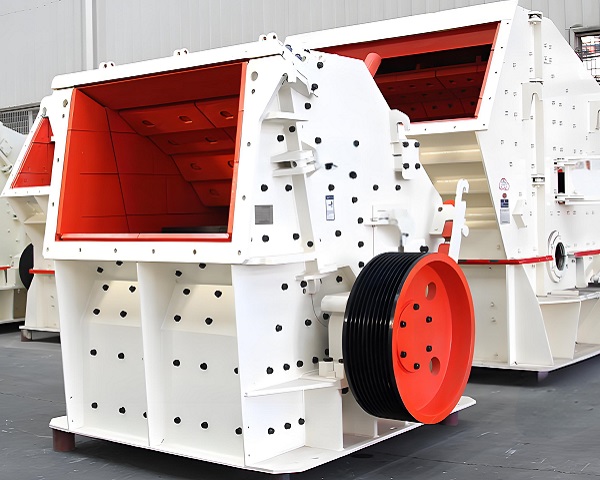

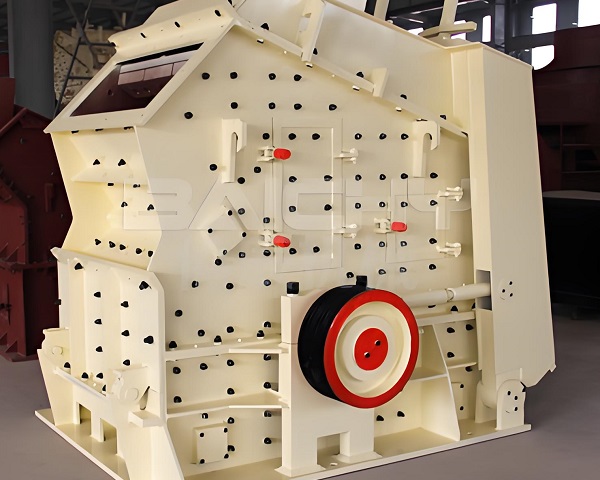

Product Picture Display of Impact Crusher for Sale

FAQ about Impact Crusher for Sale

> 1. What is the working principle of the impact crusher?

The impact crusher uses the hammer on the high-speed rotating rotor to hit and crush the material. After the material enters the crushing chamber, it is first crushed by the high-speed impact of the hammer, and at the same time, the material is thrown to the impact plate, collides with the impact plate and is crushed again. After that, the material rebounds back to the hammer action area and continues to be impacted by the hammer. This impact and collision are repeated many times until the material is crushed to the required particle size and finally discharged from the discharge port. This process is like constantly hitting a stone with a hammer, while letting the stone bounce and collide repeatedly in a specific space, thereby achieving efficient crushing.

> 2. What materials are suitable for the impact crusher?

The impact crusher is suitable for processing various medium hardness and soft materials. In the mining field, it can crush non-metallic ores such as limestone, gangue, and shale; in the building materials industry, it can process construction waste, concrete blocks, etc., and crush them into recycled aggregates for road paving, etc.; in the coal industry, it can be used to crush raw coal to make its particle size meet the requirements of washing; in the chemical industry, it can crush materials such as gypsum and coke. However, for high-hardness and highly abrasive materials such as granite and basalt, the plate hammer and impact plate wear faster during crushing, and the equipment loss is large.

> 3. What are the advantages of impact crushers compared to other crushing equipment?

The impact crusher has obvious advantages. It has a large crushing ratio and can crush large pieces of material into smaller particle sizes at one time, reducing the subsequent crushing process. The product has good particle shape, and the crushed materials are mostly cubic with low needle-like content, which meets the requirements of high-quality sand and gravel aggregates. The structure is simple, maintenance is convenient, and parts are easy to replace, which reduces maintenance costs and downtime. In addition, it also has an iron protection function. When an unbreakable object enters the crushing chamber, the plate hammer automatically retreats under force to avoid equipment damage.

> 4. How to choose the right impact crusher model?

Choosing the right model requires comprehensive consideration of many factors. First, clarify the properties of the material to be crushed, including hardness, humidity, particle size, etc. Different materials have different requirements for equipment performance. For example, when crushing materials with high humidity, the anti-blocking performance of the equipment should be considered. Then determine the production requirements, that is, the amount of material to be processed per hour (production capacity) and the desired output particle size. If the production volume is large and the output particle size is required to be fine, you must choose equipment of corresponding specifications. At the same time, consider the actual conditions such as the size of the installation site and power supply to ensure that the equipment can be installed and operated normally.

> 5. How to deal with the wear of the plate hammer of the impact crusher?

When the plate hammer of the impact crusher is worn, it can be repaired or replaced. If the wear is light, the worn part of the plate hammer can be repaired by surfacing, spraying, etc., to restore its size and performance and extend its service life. If the wear is severe and cannot be repaired, a new plate hammer needs to be replaced. When replacing, first stop the machine and cut off the power supply. According to the steps in the equipment operation manual, remove the bolts and other parts that fix the plate hammer, carefully remove the old plate hammer, install the new plate hammer, and ensure that it is firmly installed to prevent loosening during operation.

> 6. How to adjust the discharge particle size of the impact crusher?

The discharge particle size of the impact crusher is mainly adjusted by adjusting the gap between the impact plate and the plate hammer. The larger the gap, the larger the discharge particle size; the smaller the gap, the smaller the discharge particle size. Some impact crushers are equipped with hydraulic adjustment devices, which can adjust the gap size conveniently and quickly through the hydraulic system. Some models use mechanical adjustment methods to change the gap by turning adjustment bolts and other parts. When adjusting the gap, ensure that the gap on both sides is uniform to ensure uniform discharge particle size. At the same time, pay attention to the adjustment range should not be too large to avoid affecting the normal operation of the equipment.

> 7. What are the daily maintenance points of the impact crusher?

Daily maintenance is essential. Regularly check the wear of vulnerable parts such as plate hammers and impact plates, and repair or replace severely worn parts in time to prevent affecting the crushing effect and equipment safety. Pay attention to the lubrication of the equipment, add lubricating oil to the rotating parts such as the rotor bearings according to the prescribed time and method to ensure its flexible operation. Check whether the fasteners of the equipment, such as bolts and nuts, are loose. If they are loose, tighten them in time. It is also necessary to clean up the debris and accumulated materials in the crushing chamber to prevent blockage and affect the normal operation and crushing efficiency of the equipment.

> 8. What are the precautions when installing the impact crusher?

When installing the impact crusher, choose a flat and solid foundation ground to ensure that the equipment is installed firmly and avoid excessive vibration during operation. Before installation, carefully check whether the various parts of the equipment are intact and whether there is any damage during transportation. According to the requirements of the equipment manual, correctly install the rotor, plate hammer, impact plate and other components to ensure that their installation position is accurate and the connection is firm. After the installation is completed, a no-load test run should be carried out to check whether the equipment is running smoothly and whether there are any abnormal sounds and vibrations. After confirmation, it can be carried out with material to ensure the normal operation of the equipment.

> 9. What factors affect the production efficiency of the impact crusher?

Production efficiency is affected by many factors. In terms of material properties, materials with high hardness, high humidity and large particle size are difficult to crush, and the efficiency will be reduced. Equipment factors, such as rotor speed, the higher the speed, the greater the impact force of the hammer, and the higher the crushing efficiency; the appropriate number and material of the hammer can also improve the crushing efficiency. The feeding method of the operator also has an impact. Uniform feeding can make the equipment run stably and improve efficiency, while uneven feeding will cause equipment load fluctuations and reduce efficiency. In addition, the maintenance of the equipment, good maintenance can ensure the normal operation of the equipment and improve production efficiency.

> 10. How to judge whether the impact crusher is faulty?

It can be judged in many ways. Judging from the running sound, the sound is stable during normal operation. If there is abnormal impact sound, friction sound or sharp noise, there may be loose parts, wear or damage. > Observe the vibration of the equipment. If the vibration amplitude is too large or irregular, it may be caused by rotor imbalance, loose foundation and other reasons. Check the discharge situation. If the discharge particle size is uneven, the output decreases or blockage occurs, it may be caused by serious wear of the hammer, improper gap between the impact plate or uneven feeding. You can also determine whether the device is faulty by checking whether the device's temperature, current and other parameters are abnormal.