A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

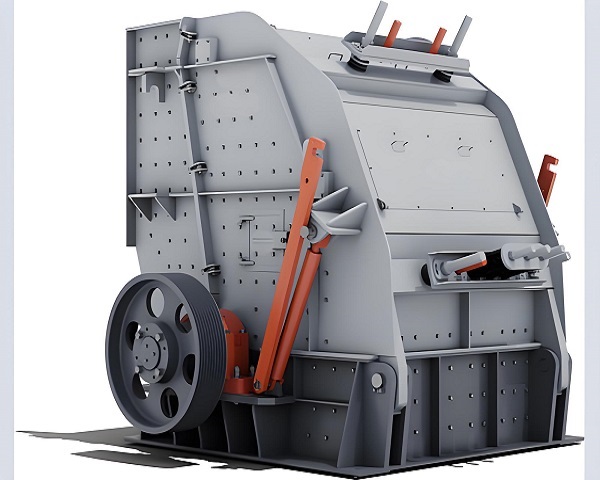

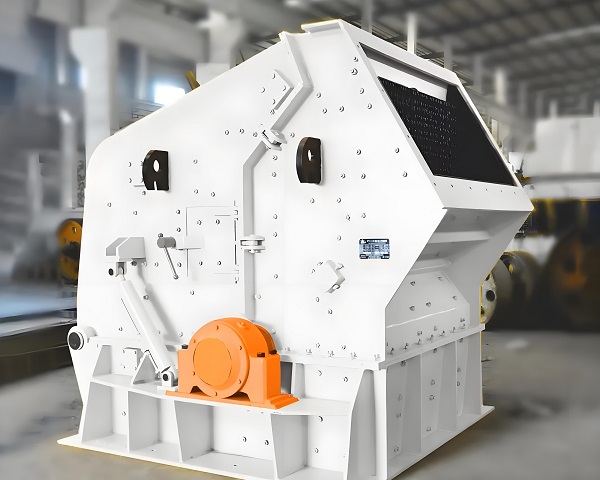

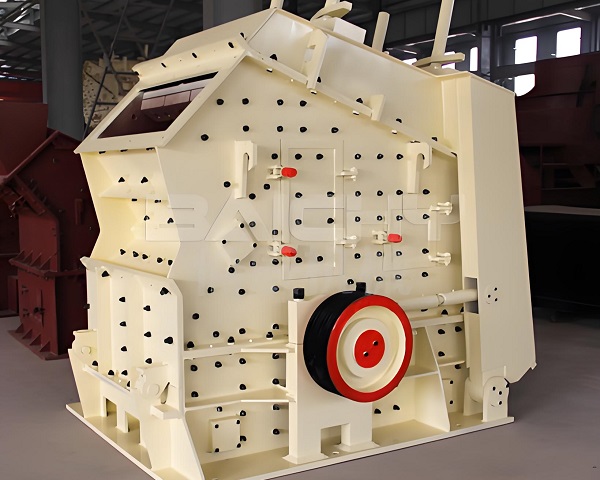

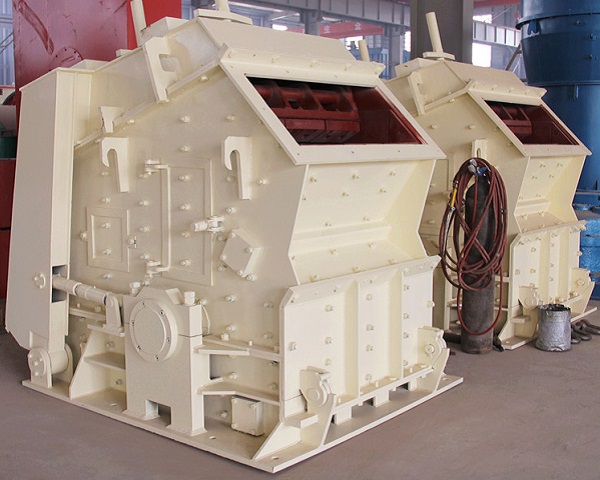

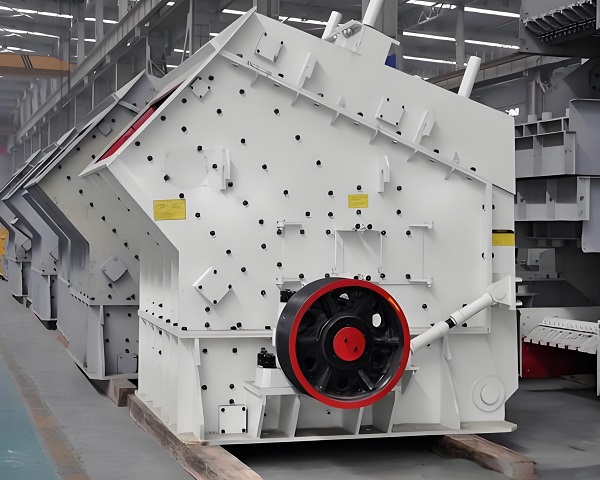

What is the Horizontal Impact Crusher

Horizontal Impact Crusher is a high-efficiency, medium-fine crushing equipment widely used in mining, building materials, highways, railways, water conservancy, chemical industry and other fields. It mainly uses the high-speed rotating rotor to violently impact the material entering the crushing chamber onto the surface of the impact plate, thereby achieving material crushing. Due to its compact structure, high crushing efficiency and excellent product particle shape, it is particularly suitable for brittle materials with medium hardness or below, such as limestone, coal gangue, construction waste, concrete, etc., so it plays an important role in the production of machine-made sand and gravel aggregates and the resource utilization of construction waste.

Structural composition

The horizontal impact crusher is mainly composed of rotor, plate hammer, impact frame (impact plate), liner, feed port, discharge port, casing, motor transmission system and other parts. Its core components are the high-speed rotating rotor and the wear-resistant plate hammer installed on it. When the rotor rotates, it generates strong kinetic energy, which drives the plate hammer to hit the material at high speed. After the impact, the material is thrown to the impact plate for further crushing, and is repeatedly impacted and sheared until it reaches the required particle size and is discharged from the discharge port.

Working Principle

When the material enters the crushing chamber, it first impacts the high-speed rotating hammer and is partially crushed; then the material is rebounded to the impact plate and crushed again, and the "strike-rebound-re-strike" cycle is continuously carried out in the chamber to form a multi-stage crushing effect. By adjusting the gap between the impact plate and the rotor, the particle size of the finished product can be accurately controlled, with high flexibility.

Technical Features and Advantages

1. Large crushing ratio

The horizontal impact crusher can achieve a finer output particle size in one crushing, and the crushing ratio can reach more than 20, which reduces the need for multi-stage crushing in traditional crushing processes and improves system efficiency.

2. Excellent particle shape

During the crushing process, the material is impacted and sheared in multiple directions at the same time, making the crushed product cubic and low in needle-like content, which is particularly suitable for the preparation of concrete aggregates and the high requirements for particle shape in highway construction.

3. Simple structure and easy maintenance

The whole machine has a reasonable structure, and the wearing parts (such as hammers and liners) adopt modular design, which is easy to replace and shortens the maintenance time. At the same time, the equipment is often equipped with a hydraulic opening device for easy inspection and daily maintenance.

4. Good cost control

Compared with cone crushers or vertical impact crushers, horizontal impact crushers have low investment costs and less operating and maintenance costs, making them an ideal choice for many small and medium-sized sand and gravel plants.

5. Wide range of applications

Suitable for crushing medium-soft and brittle materials with a compressive strength not exceeding 150-200 MPa, especially widely used in limestone crushing production lines. By properly adjusting the structural parameters, it can also be used for construction waste recycling and waste treatment such as slag and coal gangue.

Applicable scenarios

Horizontal impact crushers are usually used for secondary crushing, that is, the medium and fine crushing link after the coarse crushing of the jaw crusher. In some process flows with high requirements for particle shape, they can also be used for end shaping. In recent years, with the development of the machine-made sand market, the application of this equipment in sand and gravel aggregate shaping production lines has increased.

Development trend

With the advancement of energy-saving and environmental protection policies, modern horizontal impact crushers are gradually developing in the direction of intelligence and environmental protection. For example, remote operation monitoring can be achieved by installing an intelligent monitoring system; dust removal, shock absorption, and noise reduction devices are equipped to meet the requirements of green mine construction. At the same time, some equipment has also realized modular and mobile design, which can be flexibly deployed at different construction sites to improve work efficiency and economic benefits.

Horizontal Impact Crusher has become the main equipment for medium-hard material crushing with its advantages of high crushing ratio, good particle shape, simple structure and wide applicability. With the continuous innovation of technology and the improvement of intelligence level, this equipment will play a more critical role in the field of sand and gravel aggregate and renewable resource processing in the future. For users who pursue high production capacity, excellent particle shape and low investment, horizontal impact crusher is undoubtedly a cost-effective choice.

Operating principle of Horizontal Impact Crusher

The working principle of the Horizontal Impact Crusher (HIC) is mainly based on the impact energy to crush materials. It is characterized by simple structure and high crushing efficiency. It is widely used in mining, building materials, cement, sand and gravel industries for medium or fine crushing of various medium hardness and brittle materials.

The working principle is as follows:

When the material enters the crusher cavity through the feeding device, it first contacts the high-speed rotating rotor. There are multiple impact hammers (plate hammers) installed on the rotor, which gain strong kinetic energy as the rotor rotates. When the material enters the rotor striking area, it is impacted by the plate hammer at high speed, so that it is crushed and thrown onto the impact liner in the crushing cavity. The material is further crushed by repeated impact, extrusion and shearing between the plate hammer and the liner.

During the whole process, the rotor of the crusher has a high linear speed (usually 30-50 m/s), so it can provide enough kinetic energy to complete the crushing of the material. After the first layer of impact, part of the material has become smaller in size and will fall into the bottom of the crushing chamber due to gravity and wind assistance; while the larger part is brought up again into the next impact zone to continue to be impacted and crushed.

In addition, the discharge particle size can be achieved by adjusting the gap between the impact plate and the rotor to meet the particle size requirements of different products. The whole process is a continuous cycle, so that the material is fully crushed until it reaches the required particle size and then discharged from the discharge port.

The horizontal impact crusher uses a high-speed rotor to drive the plate hammer to impact and crush the material, and cooperates with the impact plate to complete the secondary or even tertiary crushing. It has the advantages of excellent particle shape, low energy consumption, and convenient maintenance. It is one of the important equipment in modern mineral processing and aggregate production lines.

Advantages and features of Horizontal Impact Crusher

Horizontal Impact Crusher, referred to as HIC, is a crushing equipment that uses high-speed rotating impact energy to crush materials. It is widely used in construction aggregate production, mining, metallurgy, cement, chemical industry and other industries. Its unique structural design and working mode give it many characteristics and significant advantages.

High crushing efficiency

Through the high-speed rotating rotor and the rationally arranged plate hammer, the material can obtain greater kinetic energy in a very short time, thereby achieving efficient crushing. Compared with traditional jaw or cone crushers, its crushing ratio is larger, and a finer particle size can be achieved in one crushing, reducing the need for the use of secondary and tertiary crushing equipment.

Excellent product particle shape

Since the impact crusher adopts the principle of combining "stone hitting stone" and "stone hitting iron", the material is not only impacted by the plate hammer during the crushing process, but also hits and rubs between the impact plates for many times, thus producing a polygonal and reasonably graded product particle shape. This particle shape is more in line with the strict requirements of construction sand and gravel for particle shape, and improves the added value of the product.

The equipment has a compact structure and is easy to maintain.

The horizontal structure layout reduces the height of the equipment, which is convenient for production line layout and installation; at the same time, HIC is usually equipped with a hydraulic opening system, which makes the equipment faster and safer when repairing, replacing hammers or liners, and reduces downtime and labor costs.

Strong adaptability and wide application

Horizontal impact crusher is suitable for various brittle materials with medium hardness, such as limestone, granite, basalt, coal gangue, construction waste, etc., and performs stably and reliably under different working conditions. In addition, by adjusting the speed, gap and impact angle, the particle size of the discharge can be flexibly controlled to meet the process requirements of different customers.

Outstanding energy-saving and environmental protection performance

Modern HIC equipment is generally equipped with high-efficiency motors, automatic lubrication systems and dust removal interfaces, which not only reduces energy consumption, but also optimizes the working environment, which is in line with the development direction of green manufacturing.

Horizontal impact crusher has become an ideal secondary or tertiary crushing equipment in many industrial fields with its advantages of high-efficiency crushing, high-quality particle shape, compact structure, simple maintenance and strong adaptability, and plays an important role in modern sand and gravel aggregate and mineral processing systems.

Technical Parameter Table of Horizontal Impact Crusher

| Parameter / Model | HIC-100 | HIC-200 | HIC-300 | HIC-400 | HIC-500 |

|---|---|---|---|---|---|

| Feed Opening Size (mm) | 610×400 | 750×500 | 1000×700 | 1200×800 | 1500×1000 |

| Max Feeding Size (mm) | 300 | 400 | 500 | 600 | 700 |

| Capacity (t/h) | 50–100 | 100–200 | 150–300 | 250–500 | 400–700 |

| Motor Power (kW) | 75 | 110 | 160 | 220 | 315 |

| Rotor Size (mm) | Φ800×1000 | Φ1000×1200 | Φ1250×1400 | Φ1400×1600 | Φ1600×1800 |

| Rotor Speed (rpm) | 600–800 | 500–750 | 500–700 | 450–650 | 400–600 |

| Discharge Adjustment Range (mm) | 0–60 | 0–80 | 0–100 | 0–120 | 0–150 |

| Number of Hammers | 4 | 4–6 | 6–8 | 8–10 | 10–12 |

| Weight (t) | 8 | 13 | 18 | 25 | 35 |

| Overall Dimensions (mm) | 2200×1700×1800 | 2600×2000×2100 | 3200×2300×2500 | 3700×2600×2800 | 4200×3000×3200 |

| Control System | Standard / Optional VFD | Standard / Optional VFD | Standard / Optional VFD | Standard / Optional VFD | Standard / Optional VFD |

| Lubrication Method | Centralized | Centralized | Centralized | Automatic | Automatic |

| Applicable Materials | Limestone, Basalt, Granite, Slag, Construction Waste, etc. | ||||

| Application Fields | Cement, Aggregates, Mining, Metallurgy, Construction Engineering | ||||

If you have any special requirements, we will customize according to your special needs.

Product Picture Display of Horizontal Impact Crusher

FAQ about Horizontal Impact Crusher

>1. What is a Horizontal Impact Crusher (HIC) and how does it work?

A Horizontal Impact Crusher (HIC) is a machine used to crush large rocks, ores, or other materials into smaller pieces by applying high-speed impact forces. Unlike vertical shaft impactors, HICs feature a horizontally mounted rotor with hammers or blow bars that strike the material as it enters the crushing chamber. The repeated impacts, along with collisions against breaker plates, reduce the material to the desired size before it exits through adjustable aprons or grates.

>2. What are the key advantages of using a Horizontal Impact Crusher?

Horizontal Impact Crushers offer several benefits, including high reduction ratios, efficient processing of medium to hard materials, and versatility in handling various feed sizes. Their horizontal design allows for easier maintenance and accessibility to internal components. Additionally, HICs produce a more uniform cubical product shape, making them ideal for aggregate and recycling applications where particle shape is critical.

>3. What types of materials can be processed with a Horizontal Impact Crusher?

HICs are suitable for crushing a wide range of materials, including limestone, concrete, asphalt, demolition debris, and softer ores. They excel in recycling applications, such as processing construction waste or demolished concrete. However, extremely hard or abrasive materials (like granite or quartzite) may cause excessive wear on blow bars and liners, requiring frequent replacements.

>4. How does a Horizontal Impact Crusher differ from other crushers like jaw or cone crushers?

Unlike jaw crushers (which use compression) or cone crushers (which rely on squeezing and shearing), HICs utilize impact forces to break materials. This results in better particle shape and higher reduction ratios in fewer stages. While jaw and cone crushers are better for hard, abrasive rocks, HICs are more efficient for softer materials and recycling due to their high-speed rotor action.

>5. What factors influence the performance of a Horizontal Impact Crusher?

Key performance factors include rotor speed, feed size, material hardness, and moisture content. Higher rotor speeds increase impact force but may accelerate wear. Proper feed size (within the crusher’s design limits) ensures optimal efficiency, while wet or sticky materials can cause clogging. Regular maintenance of blow bars, aprons, and liners also significantly impacts output quality and machine longevity.

>6. How do you maintain a Horizontal Impact Crusher to ensure longevity?

Routine maintenance includes inspecting and replacing worn blow bars, breaker plates, and aprons; checking rotor balance and bearings; and ensuring proper lubrication. Monitoring vibration levels helps detect misalignment or imbalance early. Keeping the crushing chamber clean prevents material buildup, which can strain the motor and reduce efficiency.

>7. What are the common applications of Horizontal Impact Crushers?

HICs are widely used in quarrying (for aggregate production), recycling (concrete, asphalt), and mining (soft to medium-hard ores). They are also employed in industrial sectors for processing materials like glass, coal, or slag. Their ability to produce uniformly shaped aggregates makes them popular in road construction and concrete production.

>8. How do you choose the right Horizontal Impact Crusher for a specific job?

Selection depends on material type, required output size, capacity needs, and operational conditions. For abrasive materials, choose a crusher with wear-resistant components. High-capacity projects may require larger rotors and higher horsepower. Consider adjustable aprons and hydraulic systems for finer control over product gradation.

>9. What are the environmental and noise considerations for HICs?

HICs generate dust and noise during operation, requiring mitigation measures like enclosed housings, water sprays, or dust suppression systems. Noise can be reduced with soundproofing materials or locating the crusher away from sensitive areas. Proper maintenance also minimizes excessive vibrations that contribute to noise pollution.

>10. What innovations are emerging in Horizontal Impact Crusher technology?

Recent advancements include smart monitoring systems (IoT sensors for real-time wear tracking), hybrid power options (electric/diesel), and improved wear materials (ceramic composites) to extend component life. Some models now feature adjustable rotor speeds and automated apron controls for optimized performance and energy efficiency.