A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

What is the CI Impact Crusher

CI impact crusher is an efficient, medium and fine crushing equipment developed by introducing mature European technology and combining the actual needs of domestic mining crushing. The equipment significantly improves the crushing efficiency, wear resistance and stability of equipment operation by optimizing the rotor structure, crushing cavity type and plate hammer material. It is widely used in the crushing process of medium-hard materials such as limestone, granite, basalt, construction waste, concrete, etc., especially suitable for construction aggregate production line, mining crushing line and solid waste resource utilization.

CI impact crusher adopts heavy-duty high-inertia rotor design, combined with a multi-functional hydraulic control system, so that the equipment has a stronger passing capacity and smoother operation performance while maintaining a high crushing ratio and a large feed opening. The hydraulic opening system not only facilitates daily maintenance and replacement of wearing parts of the equipment, but also greatly reduces the maintenance work intensity and downtime, and improves the overall operation efficiency. At the same time, the position of the impact frame is adjustable, which can flexibly control the discharge particle size to meet different production needs.

In terms of structural design, CI products focus on modularization and integrated manufacturing, simplifying the installation process and improving the reliability of the whole machine. The advanced dustproof and lubrication system design effectively extends the service life of bearings and key components. The equipment can also be equipped with an intelligent monitoring system to realize functions such as remote status monitoring, automatic alarm and operation data recording, and improve the automation level of the entire line.

The CI impact crusher performs well in energy saving and consumption reduction. It adopts high-efficiency motors and power transmission systems to significantly reduce unit energy consumption. In terms of environmental protection, the optimized crushing chamber and discharge design can effectively reduce dust and noise emissions, which is more in line with the requirements of green mines and sustainable development.

The CI impact crusher is an ideal medium and fine crushing equipment in modern sand and gravel production and mine crushing. Its high efficiency, low maintenance, intelligence and environmental protection performance make it the preferred product for upgrading mining equipment.

Operating principle of CI Impact Crusher

The working principle of CI series impact crusher is mainly based on the comprehensive crushing method of "stone hitting stone" and "stone hitting iron". The material is thrown to the impact plate by the high-speed rotating rotor to achieve the crushing effect. This equipment is widely used for secondary or tertiary crushing of medium-hard materials and has wide application value in mining, building materials, chemical industry, highway, railway and other fields.

When the material enters the crushing chamber from the feed port, it is first impacted by the plate hammer on the high-speed rotating rotor. The high-speed moving plate hammer throws the material to the impact plate arranged in the crushing chamber. After hitting the impact plate, the material is forced to rebound back to the crushing area and hit by the plate hammer again. This process is repeated continuously, so that the material is quickly crushed into the required particle size in multiple impacts, shearing and collisions. The crushed material is discharged from the discharge port under the action of gravity to form finished particles that meet the requirements.

The key structures of CI series impact crusher include heavy-duty high-inertia rotor, high-chrome wear-resistant plate hammer, adjustable impact frame and hydraulic opening device. Among them, the heavy rotor ensures greater crushing kinetic energy and improves crushing efficiency; the plate hammer is made of high chromium alloy casting, which has strong wear resistance and prolongs the service life; the multi-stage impact frame can be flexibly adjusted according to different working conditions, so as to control the discharge particle size and optimize the finished product particle shape; the hydraulic opening system provides great convenience for equipment maintenance and component replacement, reducing downtime.

The CI impact crusher adopts advanced keyless connection technology to ensure the smooth and reliable operation of the transmission part. At the same time, it is equipped with overload protection and automatic lubrication system to improve the safety and continuity of equipment operation. During the working process, the optimized design of the crushing chamber structure can effectively reduce the probability of material blockage and improve the throughput and production efficiency of the whole machine.

The CI series impact crusher repeatedly crushes the material to the target particle size through the interaction between the high-speed rotating rotor and the fixed impact device. It has many advantages such as large crushing ratio, excellent finished product particle shape, compact structure, and simple operation and maintenance. It is an ideal choice among the current medium and fine crushing equipment.

Advantages and features of CI Impact Crusher

As a new generation of high-efficiency medium and fine crushing equipment, CI impact crusher integrates advanced European technology and localized improved design, and has the remarkable characteristics of optimized structure, high efficiency and strong adaptability. It not only improves the crushing capacity and production efficiency on the basis of traditional impact crusher, but also realizes comprehensive upgrade in terms of intelligence, safety and environmental protection performance. It is widely used in mining, construction, transportation, water conservancy and other fields, and is an important equipment in modern sand and gravel aggregate production line and ore processing system.

CI impact crusher has the significant advantages of large crushing ratio and excellent finished product particle shape. The equipment adopts optimized crushing chamber structure and high inertia heavy rotor, combined with high chromium alloy plate hammer, which can achieve strong impact crushing. The material forms cubic particles in the process of multiple impacts and shearing, with low needle-like content, which greatly meets the production requirements of high-standard sand and gravel aggregate.

The equipment has the advantages of compact structure and modular design. The overall structure is more reasonable, small footprint, easy to install and arrange. At the same time, the key components are assembled in a modular way, which is convenient for maintenance and replacement, shortens the maintenance time, and improves the equipment attendance rate.

In terms of maintenance and operation, CI is equipped with the most advanced hydraulic opening system, which can quickly open the crushing chamber to replace and repair the internal vulnerable parts such as hammers and impact plates without complex lifting equipment, significantly reducing labor intensity and maintenance costs. In addition, the impact frame position is adjustable, and the operator can flexibly control the discharge particle size according to the actual working conditions to meet the diversified production needs.

CI impact crusher also attaches importance to the safety of operation and intelligent management. The equipment can be equipped with automatic lubrication system, overload protection device and intelligent monitoring system to grasp the key parameters such as operation status and vibration temperature in real time, alarm in time, prevent failure, and improve service life and operation stability.

In terms of energy saving and environmental protection, CI effectively improves the energy efficiency ratio and reduces unit energy consumption by optimizing the rotor kinetic energy and cavity layout. At the same time, the equipment has smooth discharge, small vibration and low noise, and can be equipped with a dust removal system to meet the requirements of green mining and environmental protection production.

CI impact crusher integrates efficient crushing, high-quality particle size, intelligent control, low maintenance, environmental protection and energy saving. It is an ideal equipment choice for fine crushing of ores. It can significantly improve the overall efficiency of the production line and help users achieve higher economic benefits and sustainable development goals.

Technical Parameter Table of CI Impact Crusher

| Specification | Unit | CI1110 | CI1213 | CI1313 | CI1415 | CI1516 |

|---|---|---|---|---|---|---|

| Rotor Size (Diameter × Width) | mm | 1100 × 1000 | 1200 × 1300 | 1300 × 1300 | 1400 × 1500 | 1500 × 1600 |

| Max Feed Size | mm | ≤ 300 | ≤ 350 | ≤ 400 | ≤ 450 | ≤ 500 |

| Discharge Size | mm | 0–60 | 0–60 | 0–70 | 0–80 | 0–80 |

| Capacity | t/h | 100–150 | 150–250 | 200–300 | 250–400 | 300–500 |

| Motor Power | kW | 132 | 160–200 | 200–250 | 250–315 | 315–400 |

| Number of Hammers | pcs | 4 | 4 | 4 | 4 | 4 |

| Rotor Speed | r/min | 980–1100 | 850–950 | 750–900 | 700–850 | 650–800 |

| Total Weight | t | ~12 | ~16 | ~20 | ~28 | ~32 |

| Dimensions (L × W × H) | mm | 2500×2200×2100 | 2800×2400×2300 | 3000×2600×2500 | 3300×2800×2700 | 3600×3000×2900 |

| Applications | - | Limestone, Coal | Granite, Basalt | Concrete Waste | Aggregates, Ore | Mining, Cement |

If you have any special requirements, we will customize according to your special needs.

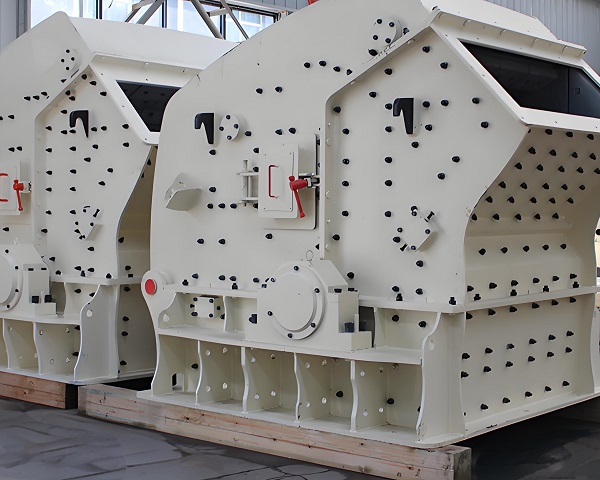

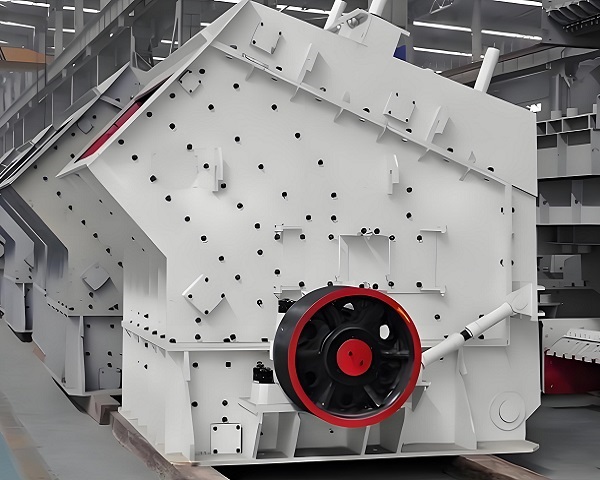

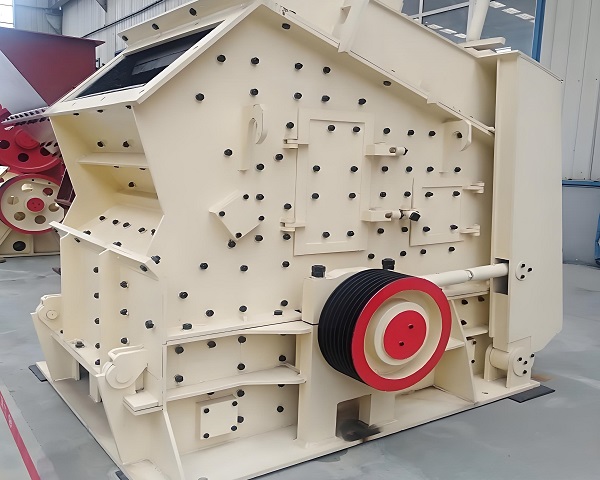

Product Picture Display of CI Impact Crusher

FAQ about CI Impact Crusher

> 1. What materials are suitable for CI impact crusher?

CI series impact crusher is suitable for various medium hardness and soft materials, such as limestone, granite, basalt, river pebbles, coal, construction waste, etc. It is especially suitable for application scenarios with high requirements for finished product particle shape, such as sand and gravel aggregates, road engineering and concrete recycling.

> 2. Compared with traditional impact crusher, what are the technical advantages of CI series?

CI series adopts advanced European technology, equipped with heavy-duty high-inertia rotor, modular design, hydraulic opening system and high-chromium alloy plate hammer, which significantly improves the crushing efficiency, particle quality and maintenance convenience. At the same time, it has better wear resistance and automation level, and the overall performance is better than traditional impact crusher.

> 3. What are the main components of CI impact crusher?

The main structure of CI series includes feed port, heavy-duty rotor, plate hammer, impact plate, liner, hydraulic opening mechanism, chassis and motor. The compact structure and reasonable layout make the equipment both durable and convenient for maintenance and repair.

> 4. What is the crushing principle?

The CI impact crusher throws the material to the impact plate through the high-speed rotating rotor, and crushes it under repeated impact, rebound and shearing. Multiple crushing cycles ensure that the material is fully cleaved, so as to obtain a finished product with good particle shape and uniform particle size.

> 5. How does the equipment adjust the discharge particle size?

The CI series controls the discharge particle size by adjusting the gap between the impact frame and the rotor. The adjustment process is simple and intuitive, and the ideal finished product particle size can be set according to different process requirements to meet the specific requirements of different projects.

> 6. Is it convenient to maintain? What is the replacement cycle of wearing parts?

The CI impact crusher adopts a hydraulic opening structure, which is convenient for operators to quickly open the casing for internal inspection and replace wearing parts such as hammers and liners. High chromium alloy wear-resistant parts have a long service life, which greatly reduces the maintenance frequency and cost.

> 7. Does it support intelligent monitoring?

Some models support the configuration of intelligent monitoring systems, which can realize real-time monitoring of key parameters such as operating status, bearing temperature, vibration value, etc., timely warn of potential faults, and improve the safety and reliability of equipment operation.

> 8. How is the energy consumption performance? Is it energy-saving?

The CI series optimizes the crushing chamber design and rotor kinetic energy utilization efficiency, and adopts an efficient motor drive system. It reduces unit energy consumption while ensuring production capacity. It is an efficient and energy-saving medium and fine crushing equipment, which is in line with the current development trend of green mining.

> 9. What application scenarios are suitable for?

CI impact crusher is widely used in mining crushing lines, aggregate production lines, construction waste recycling, water conservancy and hydropower projects, highway and railway construction and other fields. It is particularly suitable for medium and fine crushing links that require excellent particle shape and high output.

> 10. What models are available? How to choose the right model?

The CI series provides multiple models (such as CI1110, CI1213, CI1313, CI1415, CI1516), each model corresponds to different feed particle size, production capacity and power requirements. Users can get professional selection suggestions from the manufacturer based on material characteristics, output requirements and site conditions.