A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

What is the Reversible Hammer Crusher

Reversible hammer crusher is a kind of crushing equipment widely used in mining, building materials, coal and other industries. It is mainly used for crushing medium hardness and brittle materials.

Working principle

The crusher is mainly composed of rotor, hammer, grate, shell and other components. The motor drives the rotor to rotate at high speed. After the material enters the crushing chamber from the feed port, it is crushed by the strong impact of the high-speed rotating hammer. Its "reversible" characteristic is reflected in the motor's ability to rotate the rotor in both positive and negative directions. When one side of the hammer is severely worn, the motor direction is changed to reverse the rotor, so that the other side of the hammer participates in the crushing work, thereby achieving uniform wear of the hammer, greatly extending the service life of the hammer, and reducing the cost of equipment use.

Performance characteristics

Large crushing ratio: It can crush large pieces of material to smaller particle size at one time, reduce subsequent crushing processes, and improve production efficiency.

High production efficiency: The high-speed rotating hammer and reasonable crushing chamber design enable the material to be crushed quickly, and the amount of material processed per unit time is large.

Simple structure: The overall structure is relatively simple, which is convenient for equipment installation, commissioning and daily maintenance.

Adjustable particle size: By replacing the grate bars of different specifications, the particle size of the output material can be flexibly adjusted to meet the requirements of different users for the particle size of the product.

Application field

In the mining industry, it can be used to crush metal ores such as iron ore and copper ore, as well as non-metallic ores such as limestone and gypsum; in the building materials industry, it can process river pebbles, granite and other materials to prepare building sand and gravel aggregates; in the coal industry, it can crush raw coal to make its particle size meet the process requirements of coal washing and coking.

Maintenance

To ensure the normal operation of the reversible hammer crusher, it is necessary to regularly check the wear of the hammer head, grate bars and other wearing parts, and replace the seriously worn parts in time; at the same time, pay attention to the lubrication of the equipment to ensure the flexible operation of each rotating part.

Operating principle of Reversible Hammer Crusher

Working Principle of Reversible Hammer Crusher

Reversible hammer crusher is a kind of efficient crushing equipment. Its core design lies in the reversible rotating rotor structure. Through this feature, it can achieve efficient crushing of materials. The following is a detailed introduction to its working principle from the main components and crushing process.

Main components and functions

Rotor: It is the core component of the crusher, consisting of a main shaft, a disc, a pin shaft and a hammer head. It is driven by a motor through a pulley or a coupling to rotate at high speed, and is the power source for driving the hammer head to perform crushing operations.

Hammer head: It is installed on the pin shaft of the rotor and is a component that directly impacts and crushes the material. The shape, material and weight of the hammer head have an important influence on the crushing effect.

Grate bar: It is installed at the bottom of the crusher and its function is to control the particle size of the material. Materials that meet the particle size requirements can be discharged through the gaps in the grate bars, while materials larger than the gaps continue to be crushed in the crushing chamber.

Casing: It constitutes the crushing chamber of the crusher, providing a closed space for material crushing, while protecting the internal components from the influence of the external environment.

Crushing process

Material entry: The material enters the crushing chamber from the feed port of the crusher. During the entry process, the material falls freely under the action of gravity.

Primary crushing: When the material enters the crushing chamber, it is immediately hit by the high-speed rotating hammer. The hammer hits the material at a very high speed, causing the material to be crushed by the huge impact force. This is similar to hitting an object with a hammer to break a large object into small pieces.

Mutual collision and counterattack: The materials that are crushed by the hammer will also collide with each other in the crushing chamber, and collide with the impact plate of the crusher (if any). These collisions further aggravate the degree of material crushing, making the material smaller.

Secondary crushing (reversible rotation advantage): As the crushing proceeds, one side of the hammer will gradually wear out. At this time, by changing the direction of the motor to make the rotor rotate in the opposite direction, the other side of the hammer begins to participate in the crushing work. This reversible rotation method not only achieves uniform wear of the hammer and extends the service life of the hammer, but also can crush the material again to improve the crushing effect.

Discharging: After multiple crushing processes, materials that meet the particle size requirements are discharged from the crusher through the gaps between the grate bars, completing the entire crushing process.

Advantages and features of Reversible Hammer Crusher

Features of reversible hammer crusher

Reversible rotation design: This is the most significant feature of the reversible hammer crusher. Its rotor can rotate in both positive and negative directions. When one side of the hammer head is severely worn, you only need to change the direction of the motor, and the other side of the hammer head can be put into work after the rotor reverses. This feature avoids the trouble of stopping and replacing the hammer head of the traditional hammer crusher after one side of the hammer head is worn, greatly improving the utilization rate of the equipment.

Efficient crushing structure: The crusher adopts a special structural design inside, and the hammer heads are reasonably distributed to form an efficient crushing area. After the material enters the crushing chamber, it will be continuously impacted by multiple hammer heads, with high crushing efficiency, and can crush large pieces of material into the required particle size in a short time.

Adjustable discharge particle size: By replacing grate bars of different specifications, the discharge particle size can be flexibly adjusted. Users can choose appropriate grate bars according to actual production needs, so as to obtain products of different particle sizes to meet diversified production requirements.

Excellent material of wear-resistant parts: hammers, grates and other vulnerable parts are made of high-strength and high-wear-resistant alloy materials, with good wear resistance, can be used for a long time in harsh working environments, reduce the frequency of component replacement, and reduce maintenance costs.

Advantages of reversible hammer crusher

Reduce the cost of use: The reversible rotation design prolongs the service life of the hammer and reduces the number of hammer replacements. At the same time, the excellent material of wear-resistant parts also reduces the loss of other vulnerable parts, thereby reducing the overall cost of equipment use.

Improve production efficiency: The efficient crushing structure and large crushing ratio enable the reversible hammer crusher to process more materials per unit time, greatly improving production efficiency and bringing higher economic benefits to the enterprise.

Easy operation and maintenance: The equipment structure is relatively simple and easy for operators to use. Daily maintenance work is also relatively convenient. For example, operations such as replacing hammers and grates do not require complex tools and techniques, and can be completed quickly, reducing downtime.

Strong adaptability: It can crush a variety of medium hardness and brittle materials, such as limestone, coal, gypsum, etc. It is widely used in mining, building materials, coal and other industries, and can meet the production needs of different industries.

Technical Parameter Table of Reversible Hammer Crusher

| Specification | Unit | PCKW-0808 | PCKW-1012 | PCKW-1214 | PCKW-1416 |

|---|---|---|---|---|---|

| Model | - | PCKW-0808 | PCKW-1012 | PCKW-1214 | PCKW-1416 |

| Rotor Diameter × Length | mm | 800 × 800 | 1000 × 1200 | 1200 × 1400 | 1400 × 1600 |

| Max Feeding Size | mm | ≤ 80 | ≤ 100 | ≤ 130 | ≤ 150 |

| Discharge Size Range | mm | 0–3 (90%) | 0–3 (90%) | 0–5 (85%) | 0–5 (80%) |

| Capacity | t/h | 40–70 | 80–120 | 150–220 | 200–320 |

| Rotor Speed | r/min | 1100 | 950 | 850 | 750 |

| Number of Hammers | pcs | 20 | 28 | 36 | 44 |

| Hammer Material | - | High Manganese Steel | High Chrome Alloy | High Chrome Alloy | High Chrome + Carbide |

| Motor Power | kW | 75 | 132 | 200 | 315 |

| Motor Speed | r/min | 1480 | 1480 | 1480 | 1480 |

| Drive Type | - | Direct Coupling | Coupling + Belt | Belt Drive | Belt Drive |

| Hydraulic Opening Mechanism | - | Yes | Yes | Yes | Yes |

| Reversible Operation | - | Supported | Supported | Supported | Supported |

| Lubrication Method | - | Manual Grease | Manual Grease | Centralized Auto | Centralized Auto |

| Overall Dimensions (L×W×H) | mm | 2200×1600×1400 | 2800×2200×1800 | 3500×2600×2000 | 4200×3000×2400 |

| Total Weight | t | 6.5 | 12.3 | 18.6 | 26.8 |

| Applicable Materials | - | Coal, Limestone, Slag | Limestone, Clay, Coal | Limestone, Shale, Gangue | Limestone, Slag, Iron Ore |

| Noise Level (No Load) | dB | ≤ 85 | ≤ 87 | ≤ 90 | ≤ 92 |

| Discharge Adjustment | - | Liner Adjustment | Hydraulic | Hydraulic | Hydraulic + Electric |

If you have any special requirements, we will customize according to your special needs.

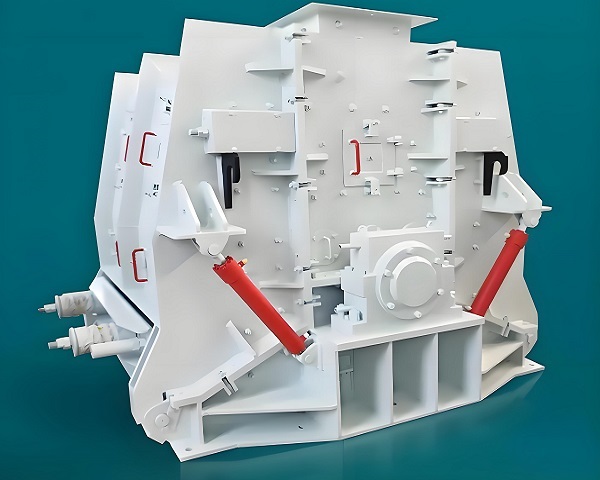

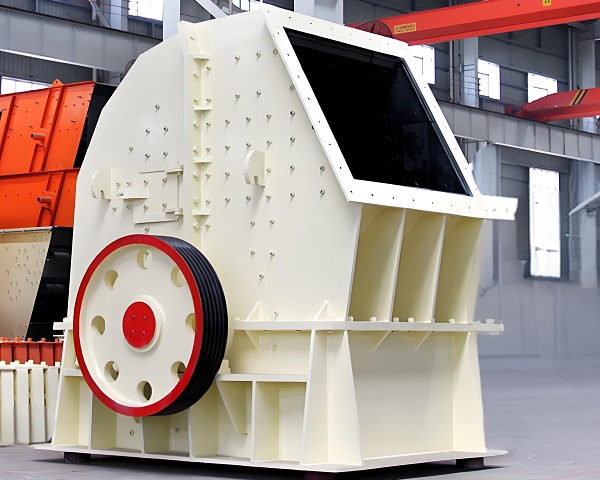

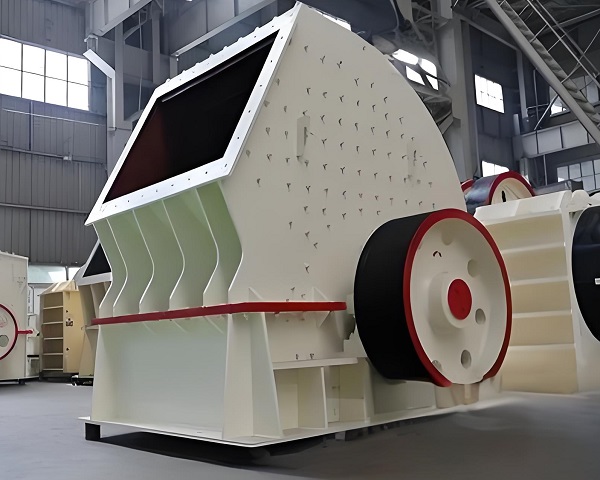

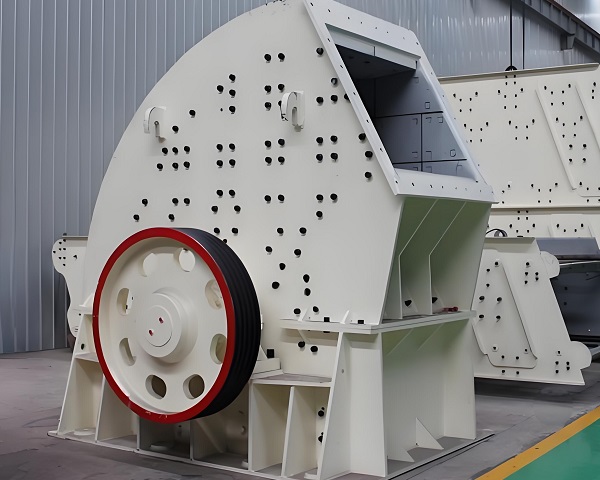

Product Picture Display of Reversible Hammer Crusher

FAQ about Reversible Hammer Crusher

>1. What is the working principle of the reversible hammer crusher?

When the reversible hammer crusher is working, the motor drives the rotor to rotate at high speed, and the material enters the crushing chamber from the feed port and is crushed by the strong impact of the high-speed rotating hammer. Its "reversible" characteristic is reflected in the fact that the motor can make the rotor rotate in both directions. When one side of the hammer is severely worn, the rotor is reversed to allow the other side of the hammer to participate in the crushing to achieve uniform wear. At the same time, the crushed materials collide with each other in the chamber, and some models of materials will also collide with the impact plate, further refining, and the materials that meet the particle size requirements are discharged through the gaps in the grate bars.

>2. What materials are suitable for reversible hammer crushers?

Reversible hammer crushers are suitable for crushing a variety of medium hardness and brittle materials. In the mining field, it can be used to crush metal ores such as iron ore and copper ore, as well as non-metallic ores such as limestone and gypsum; in the building materials industry, it can process river pebbles, granite, etc. to prepare building sand and gravel aggregates; in the coal industry, raw coal can be crushed to make its particle size meet the requirements of subsequent processes such as coal washing and coking. However, for materials with high hardness, high toughness or high viscosity, the crushing effect may not be ideal.

>3. What are the advantages of reversible hammer crusher over traditional hammer crusher?

The advantages of reversible hammer crusher are significant. Its reversible rotation design prolongs the service life of the hammer head, avoids the trouble of stopping and replacing the hammer head of the traditional hammer crusher after one-side wear, and improves the utilization rate of the equipment. At the same time, it reduces the cost of use, reduces the number of hammer head replacements, and the wear-resistant parts are made of excellent material, which reduces the loss of other wearing parts. In addition, the equipment is easy to operate and maintain, with a relatively simple structure. It is convenient to replace the hammer head and grate bars on a daily basis, which reduces downtime. It also has the characteristics of efficient crushing and high production efficiency.

>4. How to choose a suitable reversible hammer crusher model?

Choosing a suitable model requires comprehensive consideration of many factors. First of all, it is necessary to clarify the properties of the material to be crushed, such as hardness, humidity, particle size, etc. Different materials have different requirements for equipment. Secondly, determine the production needs, including production capacity (the amount of material to be processed per hour) and discharge particle size requirements. In addition, the actual conditions such as the size of the installation site and the power supply should also be considered. Considering these factors, refer to the technical specifications provided by the manufacturer and select a model that meets production needs and is suitable for site conditions.

>5. How to deal with the wear of the hammer head of the reversible hammer crusher?

When the hammer head of the reversible hammer crusher is worn, its reversible rotation characteristics can be used to reverse the rotor by changing the direction of the motor, so that the unworn side of the hammer head can participate in the crushing work and achieve uniform wear. If both sides of the hammer head are worn to a certain extent, they need to be replaced. When replacing, first stop the machine and cut off the power supply. According to the steps in the equipment operation manual, disassemble the pin shaft and other parts that fix the hammer head, remove the old hammer head, install the new hammer head, and ensure that it is firmly installed.

>6. How to adjust the discharge particle size of the reversible hammer crusher?

Adjusting the discharge particle size of the reversible hammer crusher is mainly achieved by replacing the grate bars of different specifications. The size of the gap between the grate bars determines the discharge particle size. If a smaller discharging particle size is required, replace the grate with a smaller gap; if a larger discharging particle size is required, replace the grate with a larger gap. When replacing the grate, make sure that the grate is firmly installed and accurately positioned to ensure the normal operation of the crusher and the quality of the discharging.

>7. What are the key points of daily maintenance of the reversible hammer crusher?

Daily maintenance is essential. Regularly check the wear of vulnerable parts such as hammer heads and grate bars, and replace severely worn parts in time to avoid affecting the crushing effect and equipment safety. Pay attention to the lubrication of the equipment, and add lubricating oil to each rotating part according to the prescribed time and method to ensure its flexible operation. At the same time, check whether the fasteners of the equipment are loose, such as bolts, nuts, etc. If they are loose, tighten them in time. In addition, it is necessary to clean up the debris and accumulated materials in the crushing chamber to prevent blockage.

>8. What are the installation precautions of the reversible hammer crusher?

When installing a reversible hammer crusher, choose a flat and solid foundation to ensure that the equipment is installed firmly. Before installation, check whether all parts of the equipment are intact and whether there is any damage during transportation. According to the requirements of the equipment manual, correctly install the rotor, hammer head, grate bars and other parts to ensure that their installation position is accurate and the connection is firm. After installation, a no-load test run should be carried out to check whether the equipment is running smoothly and whether there are any abnormal sounds and vibrations. After confirmation, it can be run with material.

>9. What factors affect the production efficiency of the reversible hammer crusher?

The production efficiency of the reversible hammer crusher is affected by many factors. In terms of material properties, the hardness, humidity, and particle size of the material will affect the difficulty and speed of crushing. The crushing efficiency of materials with high hardness, high humidity, and large particle size is relatively low. Equipment factors such as rotor speed, number and weight of hammer heads, etc., the higher the speed, the more appropriate the number and weight of hammer heads, and the higher the crushing efficiency. In addition, the operating level of the operator and the maintenance of the equipment will also affect the production efficiency.

>10. How to judge whether the reversible hammer crusher is faulty?

There are many ways to judge whether the reversible hammer crusher is faulty. Judging from the running sound, the sound is stable during normal operation. If there is abnormal impact, friction or sharp noise, there may be problems such as loose parts, wear or damage. Observe the vibration of the equipment. If the vibration amplitude is too large or irregular, it may be caused by rotor imbalance, loose foundation, etc. Check the discharge. If the discharge particle size is uneven, the output is reduced or there is a blockage, it may be caused by damaged grate bars, severe wear of the hammer head or uneven feeding.