A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

What is the Heavy Hammer Crusher

The heavy hammer crusher is mainly used for the primary crushing of medium and low hardness materials, and is suitable for mining, building materials, chemical industry, metallurgy and other industries. The coarse crushing of brittle materials, cement production line, sand and gravel aggregate production, construction waste recycling and coarse crushing operation scene.

In modern industrial production, material crushing is an indispensable key process in many industries such as mining, building materials, and metallurgy. With the advancement of technology and the improvement of environmental protection requirements, efficient and energy-saving crushing equipment is increasingly favored by the market. As a coarse crushing equipment with a large crushing ratio and high processing capacity, the heavy hammer crusher has excellent performance in the primary crushing of various medium and low hardness materials due to its simple structure, convenient maintenance, and strong adaptability. This article will systematically introduce the heavy hammer crusher from multiple dimensions such as equipment structure, working principle, performance characteristics, and application fields, and provide equipment selection and application references for users in related industries.

1. Equipment Introduction

The heavy hammer crusher is a coarse crushing equipment that uses heavy hammers and high-speed rotors to achieve strong impact crushing. It has the characteristics of simple structure, large crushing ratio (up to 40:1), high production capacity, etc. It is widely used for primary crushing of medium and low hardness materials.

2. Structural principle

The core components include rotor system, impact liner, adjustable screen plate and heavy frame. The material is crushed by hammer impact and liner collision. The screen plate controls the discharge particle size. The hydraulic cover design is easy to maintain.

3. Performance advantages

The single machine has a large crushing ratio and lower energy consumption than the extrusion crusher; the discharge particle size can be flexibly adjusted by replacing the screen plate (5-50mm); it has high tolerance for moisture content and impurities, and the modular design makes maintenance convenient.

4. Application field

It is mainly used for brittle material processing in mines (limestone, gypsum, etc.), pre-crushing of cement raw materials, recycling of construction waste (concrete blocks, bricks and tiles), and chemical metallurgical industries (phosphate ore, slag).

5. Key points for use

The selection should consider the material hardness (≤200MPa) and production capacity requirements; the hammer wear and bearing lubrication should be checked regularly during operation, and metal foreign matter is strictly prohibited from entering. It is recommended to configure an iron remover protection device.

6. Development trend

Develop in the direction of intelligence (condition monitoring), environmental protection (dust control) and multi-function (adjustable crushing mode), continuously improve reliability and reduce maintenance costs.

The heavy hammer crusher has become an important equipment in modern crushing technology with its unique design concept and excellent performance. Through analysis, it can be seen that the equipment not only has technical advantages such as large crushing ratio and high production capacity, but also can adapt to production needs under various working conditions. From mining aggregate production to construction waste recycling, from cement raw material processing to chemical metallurgical applications, the heavy hammer crusher has shown a wide range of application prospects. With the continuous integration of intelligent and environmentally friendly technologies, the heavy hammer crusher will continue to optimize in terms of reliability improvement and energy consumption reduction in the future, creating greater value for users. Selecting a suitable heavy hammer crusher and standardizing its use and maintenance will significantly improve production efficiency, reduce operating costs, and bring considerable economic benefits to the enterprise.

Operating principle of Heavy Hammer Crusher

The following will introduce the heavy hammer crusher in detail from the aspects of structure and working principle.

Structural composition

The heavy hammer crusher is mainly composed of a frame, a rotor, a hammer, a screen plate (or a liner), a feed port, a discharge port, a transmission device, etc. Its core components are the rotor and the hammer. The rotor is a high-speed rotating part composed of a main shaft, a disc and a hammer shaft, and the hammer is fixed on the hammer shaft. The entire crusher is driven by an electric motor, and the rotor is driven to rotate by a pulley or a coupling.

Working principle

The working process of the heavy hammer crusher can be briefly described as follows: after the material enters the crushing chamber, driven by the high-speed rotating rotor, the hammer strikes, shears and impacts the material at high speed, so that the material is quickly crushed. At the same time, the particles are further refined in the mutual collision between the hammer strike and the material. After the material is crushed to the required particle size under multiple strikes, it is discharged through the aperture of the screen plate. The material that does not meet the particle size requirements will continue to be circulated and crushed in the crushing chamber.

Its working principle is based on the impact crushing of materials by high-speed rotating hammers, combined with the screen plate to control the particle size, thus achieving efficient, continuous and stable crushing operations.

Advantages and features of Heavy Hammer Crusher

As a highly efficient crushing equipment, heavy hammer crusher is widely used in many industrial fields such as mining, cement, coal, metallurgy, highway, construction waste treatment, etc. Compared with traditional jaw crusher, cone crusher and ordinary hammer crusher, heavy hammer crusher has significant advantages in structural design, crushing performance, operation efficiency and maintenance cost. The following will summarize its characteristics and advantages in detail from multiple angles.

1. Simple structure and stable operation

The heavy hammer crusher adopts a structural design that integrates crushing and shaping. The overall layout is compact and reasonable, which reduces the complex process flow of traditional crushing equipment. Its core structure includes frame, rotor, hammer head, screen plate, transmission device, etc., especially the rotor system is dynamically balanced to ensure the stability and safety of the equipment during high-speed operation, and effectively reduce vibration and noise.

2. Large crushing ratio, one-time forming

The biggest advantage of heavy hammer crusher is its super large crushing ratio, which can reach 20\~50 times, which is much higher than traditional jaw crusher and cone crusher. It can directly crush large materials with a feed size of 600-1800mm to less than 20mm, achieving the crushing goal of "one-time forming", eliminating the process of secondary or even tertiary crushing, greatly improving work efficiency, and significantly reducing equipment investment and operating costs.

3. High production efficiency and low energy consumption

Due to its one-time forming ability, the heavy hammer crusher can save a lot of energy consumption in intermediate crushing, screening, transportation and other links when processing materials. In addition, its hammer head design is optimized, with a large striking area and strong striking force, which can quickly crush materials and reduce crushing time, thereby improving production efficiency as a whole. The power consumption per ton of material is significantly lower than that of traditional crushing equipment, with good energy-saving effects.

4. Excellent finished product particle shape and reasonable grading

During the crushing process, the heavy hammer crusher not only achieves primary crushing through high-speed collision between the hammer head and the material, but also relies on mutual collision between materials to further improve the particle shape and particle uniformity. The finished product has a controllable particle size, a cubic particle shape, and no excessive flaky or needle-shaped particles, which is very suitable as a high-quality aggregate for concrete and highway engineering.

5. Strong adaptability and wide application

Heavy-duty hammer crushers are suitable for crushing a variety of medium-hard and brittle materials, such as limestone, shale, coal gangue, gypsum, weathered rock, slag, etc. Whether in a dry environment or a workplace with high moisture content, it can operate stably, is not easy to clog, and has very strong adaptability. It is particularly suitable for various industrial scenarios such as raw material crushing in cement plants, resource processing of construction waste, and production of sand and gravel aggregates.

6. Wear-resistant wearing parts and low maintenance costs

The core striking component of the equipment, the hammer head, is mostly made of high manganese steel, high chromium cast iron or composite materials, and has strong impact resistance and wear resistance. The hammer head is quick and easy to replace, and other components such as screen plates and linings are also easy to maintain and replace, which shortens the equipment downtime, reduces maintenance costs, and increases the equipment's operating time and economic benefits.

7. Superior environmental performance

Modern heavy-duty hammer crushers pay more and more attention to environmental performance, and are usually equipped with dust removal devices and sealing structures to reduce dust leakage and noise pollution, which meets the current policy requirements of green mining and environmentally friendly production. At the same time, since the equipment can reduce the intermediate links, it also means that the energy consumption and dust points of the entire production system are also less, which is more conducive to environmental protection.

8. Intelligent control, easy operation

With the development of automation technology, some high-end models of heavy hammer crushers have been equipped with automatic lubrication systems, intelligent temperature monitoring, overload protection, PLC control and other functions, which further improve the convenience and safety of equipment operation. Workers do not need to be on duty for a long time, which greatly saves labor costs and reduces operating risks.

Heavy hammer crushers have become an indispensable and efficient equipment in modern crushing processes with their advantages of "one-time molding, high efficiency, low energy consumption, good particle shape, easy operation and strong adaptability". It not only optimizes the crushing process, reduces energy consumption and costs, but also promotes the development of green and environmentally friendly crushing technology. In the future, with the continuous integration of intelligence and energy-saving and environmental protection technologies, heavy hammer crushers will play a greater role in more industrial fields.

Technical Parameter Table of Heavy Hammer Crusher

| Model | Max Feed Size (mm) | Discharge Size (mm) | Capacity (t/h) | Motor Power (kW) | Rotor Diameter (mm) | Rotor Length (mm) | Hammer Quantity | Rotor Speed (r/min) | Total Weight (t) | Dimensions (mm) |

|---|---|---|---|---|---|---|---|---|---|---|

| PCZ-0808 | ≤400 | ≤25 | 50–100 | 90–110 | 800 | 800 | 8 | 800–1000 | 8 | 2300×1800×2000 |

| PCZ-1010 | ≤600 | ≤25 | 100–200 | 132–160 | 1000 | 1000 | 10 | 750–950 | 14 | 2600×2100×2300 |

| PCZ-1212 | ≤800 | ≤25 | 200–300 | 200–250 | 1200 | 1200 | 12 | 700–900 | 22 | 3100×2500×2700 |

| PCZ-1414 | ≤1000 | ≤25 | 300–500 | 315–400 | 1400 | 1400 | 14 | 650–850 | 32 | 3600×2900×3100 |

| PCZ-1615 | ≤1200 | ≤25 | 500–800 | 500–630 | 1600 | 1500 | 18 | 600–800 | 45 | 4200×3200×3600 |

| PCZ-1720 | ≤1200 | ≤25 | 800–1000 | 710–800 | 1700 | 2000 | 22 | 550–750 | 60 | 4700×3500×4000 |

| PCZ-1922 | ≤1500 | ≤25 | 1000–1600 | 900–1000 | 1900 | 2200 | 26 | 500–700 | 75 | 5200×3900×4500 |

If you have any special requirements, we will customize according to your special needs.

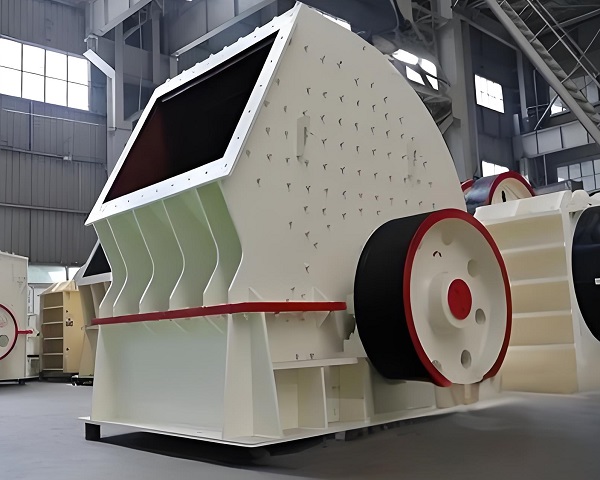

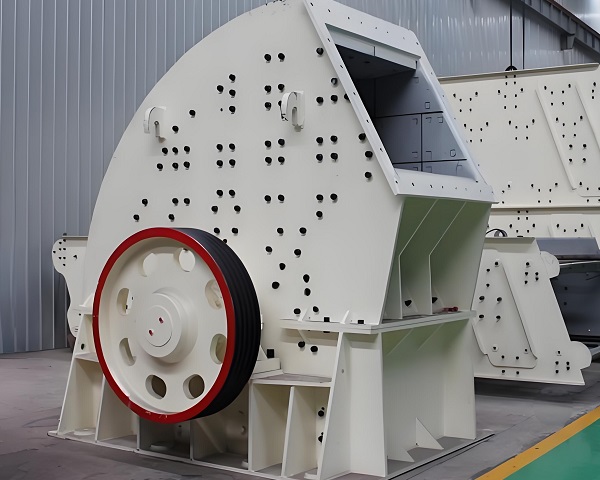

Product Picture Display of Heavy Hammer Crusher

FAQ about Heavy Hammer Crusher

>1. What is the working principle of a heavy hammer crusher?

The heavy hammer crusher uses a high-speed rotating rotor to drive a heavy hammer to forcefully impact and crush the material. The material is crushed by the hammer, the impact plate and the mutual friction. Finally, the discharge particle size is controlled by the screen plate to achieve efficient coarse crushing.

>2. What materials are suitable for a heavy hammer crusher?

This equipment is suitable for medium and low hardness brittle materials with a compressive strength of ≤200MPa, such as limestone, coal gangue, gypsum, shale, etc., but not suitable for high hardness (such as granite) or high toughness (such as metal ore) materials.

>3. What are the advantages of a heavy hammer crusher over a jaw crusher?

The heavy hammer crusher has a larger crushing ratio (up to 40:1), higher processing capacity and lower energy consumption, and the product particle shape is more uniform, which is suitable for one-time coarse crushing and reduces the need for secondary crushing.

>4. How to adjust the discharge particle size of a heavy hammer crusher?

The particle size of the discharge material can be controlled by replacing the sieve plates with different apertures or adjusting the gap of the impact liner. The adjustable range is usually 5-50mm to meet different production needs.

>5. What are the main vulnerable parts of the heavy hammer crusher?

The main vulnerable parts include hammer head, impact liner, sieve plate, etc. Among them, the hammer head wears the fastest and needs to be checked and replaced regularly to ensure the crushing efficiency and equipment stability.

>6. How is the heavy hammer crusher used in construction waste treatment?

The equipment can efficiently crush construction waste such as concrete blocks, bricks and tiles, and produce recycled aggregates for roadbed or building materials. It has the characteristics of large processing capacity and strong adaptability.

>7. How to maintain the heavy hammer crusher to extend its service life?

Regularly check the hammer head wear, bearing lubrication and fastener status, replace damaged parts in time, and avoid metal foreign matter from entering the crushing chamber to reduce the risk of equipment damage.

>8. What factors affect the production capacity of the heavy hammer crusher?

The main influencing factors include material hardness, feed size, rotor speed and screen plate specifications. Reasonable matching of these parameters can optimize production efficiency.

>9. What are the environmental protection designs of heavy hammer crushers?

Modern models use closed structures, dust removal systems and noise reduction technologies to reduce dust and noise pollution and meet environmental protection production requirements.

>10. What is the development trend of heavy hammer crushers in the future?

Intelligence (real-time monitoring, automatic adjustment), energy saving (optimization of energy consumption) and multi-function (switchable crushing mode) are the main development directions to improve equipment performance and adaptability.