A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

What is the Hammer Crusher for Sale

Hammer crusher is a common crushing equipment, which plays an important role in many industrial fields. The following is a detailed introduction from multiple aspects.

Working principle

The hammer crusher mainly relies on the high-speed rotating hammer to crush the material. When the material enters the crushing chamber of the crusher, it is violently impacted by the high-speed rotating hammer. At the same time, the materials will collide with each other and be crushed into smaller particles. In addition, some crushers are also equipped with impact plates. After the material is hit by the hammer head against the impact plate, it is impacted and crushed again. When the crushed material reaches the specified particle size, it will be discharged through the gap of the grate bars.

Structural composition

Rotor: It is the core component of the hammer crusher, which consists of a main shaft, a disc, a pin shaft and a hammer head. The rotor rotates at high speed driven by the motor, providing a strong impact force for the hammer head.

Hammer head: It directly impacts and crushes the material, and its material and shape have an important influence on the crushing effect. Common hammer head materials include high manganese steel, alloy steel, etc. Different materials are suitable for crushing materials of different hardness.

Grate bars: used to control the particle size of the material. The materials that meet the requirements can be discharged through the gaps of the grate bars, while the larger materials continue to be crushed in the crushing chamber.

Shell: constitutes the crushing chamber of the crusher, plays the role of protecting the internal components and accommodating materials.

Performance characteristics

Large crushing ratio: can crush large pieces of material to smaller particle size at one time, reducing the subsequent crushing process and improving production efficiency.

High production efficiency: the high-speed rotating hammer head and reasonable crushing chamber design enable the material to be crushed quickly, and the amount of material processed per unit time is large.

Simple structure: the overall structure is relatively simple, which is convenient for the installation, commissioning and daily maintenance of the equipment.

Strong adaptability: can crush a variety of medium hardness and brittle materials, such as limestone, coal, gypsum, etc.

Application field

Widely used in mining, building materials, coal, chemical industry and other industries. In the mining industry, it is used for coarse and medium crushing of ore; in the building materials industry, it can process various rocks to prepare building sand and gravel aggregates; in the coal industry, it is used for the crushing of raw coal; in the chemical industry, it is used to process related brittle chemical raw materials.

Operating principle of Hammer Crusher for Sale

Hammer crusher is a device that uses high-speed rotating hammers to impact and crush materials. Its working principle can be summarized as the following key links:

Material entry and initial impact

The material enters the crushing chamber from the feed port of the hammer crusher. At this time, the motor drives the rotor to rotate at high speed, and the hammer installed on the rotor also moves at high speed. As soon as the material enters the crushing chamber, it will be immediately hit by the high-speed rotating hammer. This is like hitting a stone quickly with a hammer. The huge kinetic energy of the hammer acts on the material instantly, causing the material to be subjected to a huge impact force. Cracks begin to appear on the surface of the material and it is initially broken into smaller pieces.

Material collision and secondary crushing

The material that is impacted and crushed by the hammer will fly out of the crushing chamber at a higher speed due to the impact force of the hammer. During the flying process, the materials will collide with each other. This collision further aggravates the degree of material crushing, just like a group of stones hitting each other in the air, and the originally larger stones will be smashed into more pieces. At the same time, some materials will also collide with the impact plate of the crusher. The impact plate is usually installed at a suitable position in the crushing chamber. When the material hits the impact plate, it will rebound and be impacted by the hammer again, achieving secondary crushing and making the material more refined.

Grate screening and discharging

After multiple impacts and collisions, the particle size of the material gradually becomes smaller. The lower part of the crusher is equipped with grate bars, and there are certain gaps between the grate bars. Materials that meet the particle size requirements can be discharged from the crusher through these gaps and become crushed products. Materials with larger particle sizes will be blocked by the grate bars and continue to remain in the crushing chamber, receiving the impact and crushing of the hammer again until the particle size meets the requirements and is discharged through the grate gaps. Through this screening mechanism, the hammer crusher can effectively control the particle size of the discharge to meet different production needs.

The special role of the reversible rotation of the rotor (some models)

Some hammer crushers have the function of reversible rotation of the rotor. When one side of the hammer head is severely worn due to long-term impact on the material, the operator can change the direction of the motor to make the rotor rotate in the opposite direction. In this way, the unworn side of the hammer can continue to participate in the crushing work, achieving uniform wear of the hammer, extending the service life of the hammer, and also improving the use efficiency and economic benefits of the crusher.

Advantages and features of Hammer Crusher for Sale

Advantages of hammer crusher

High crushing ratio: hammer crusher can crush large pieces of material into smaller particle size at one time. For example, when processing limestone, it can directly crush stones with a diameter of several hundred millimeters to tens of millimeters or even smaller, greatly reducing the subsequent crushing process, reducing production costs and equipment investment. This large crushing ratio feature makes it have obvious advantages in production scenarios where large pieces of raw materials need to be quickly processed into smaller particles.

High production efficiency: The high-speed rotating hammer head gives the material a strong impact force, and the material is hit by the hammer head multiple times in the crushing chamber and the materials collide with each other, and the crushing speed is fast. Taking the hourly processing volume as an example, compared with some traditional crushing equipment, the hammer crusher can process more materials in the same time, improve the production capacity of the overall production line, and bring higher economic benefits to the enterprise.

Low operating cost: On the one hand, its structure is relatively simple and the number of parts is small, which makes the manufacturing, installation and maintenance costs of the equipment relatively low. On the other hand, some hammer crushers adopt a reversible rotor design, and the hammer head can be reversed after wear, which prolongs the service life of the hammer head, reduces the frequency of hammer head replacement, and reduces the consumption cost of wearing parts.

Strong adaptability: It can handle a variety of medium-hardness and brittle materials, whether it is iron ore and copper ore in mines, granite and basalt in the building materials industry, or raw coal in the coal industry, etc., all can be effectively crushed. This wide adaptability makes it useful in different industries, and enterprises do not need to replace multiple crushing equipment for different materials.

Characteristics of hammer crusher

Simple structure: It is mainly composed of rotor, hammer head, grate bar and shell, with compact structure and small footprint. This not only facilitates the installation and layout of the equipment, but also reduces the cost of plant construction. Moreover, its internal structure is relatively simple, and it is easy for operators to understand and master the working principle and operation method of the equipment.

Various crushing methods: In addition to the impact crushing of the hammer head on the material, the material will collide with each other and with the impact plate in the crushing chamber. The combination of multiple crushing methods makes the crushing effect better and the discharge particle size more uniform.

Flexible adjustment: By replacing grate bars of different specifications, the discharge particle size can be easily adjusted to meet the requirements of different production processes for product particle size. For example, when producing sand and gravel aggregates of different specifications, it is only necessary to replace the corresponding grate bars without large-scale modification of the equipment. , so that the rotor rotates in the opposite direction. In this way, the unworn side of the hammer head can continue to participate in the crushing work, achieving uniform wear of the hammer head, extending the service life of the hammer head, and also improving the use efficiency and economic benefits of the crusher.

Technical Parameter Table of Hammer Crusher for Sale

| Specification | Unit | PC-400×300 | PC-600×400 | PC-800×600 | PC-1000×800 | PC-1200×1000 |

|---|---|---|---|---|---|---|

| Model | - | PC-400×300 | PC-600×400 | PC-800×600 | PC-1000×800 | PC-1200×1000 |

| Rotor Diameter × Length | mm | 400 × 300 | 600 × 400 | 800 × 600 | 1000 × 800 | 1200 × 1000 |

| Max Feeding Size | mm | ≤ 100 | ≤ 180 | ≤ 200 | ≤ 250 | ≤ 300 |

| Discharge Size Range | mm | 0–10 | 0–15 | 0–20 | 0–25 | 0–30 |

| Capacity | t/h | 5–10 | 10–25 | 20–50 | 50–100 | 80–150 |

| Number of Hammers | pcs | 12 | 16 | 20 | 32 | 40 |

| Motor Power | kW | 7.5–11 | 18.5–22 | 30–55 | 55–90 | 90–132 |

| Motor Speed | r/min | 1450 | 1450 | 1450 | 980 | 980 |

| Total Weight | t | 0.8 | 1.5 | 3.1 | 6.5 | 9.5 |

| Dimensions (L×W×H) | mm | 900×670×860 | 1200×1050×1200 | 1500×1200×1500 | 1800×1600×1800 | 2200×1800×2000 |

| Applications | - | Coal, Brick, Stone | Limestone, Slag | Limestone, Gypsum | Clinker, Shale | Cement, Ore |

If you have any special requirements, we will customize according to your special needs.

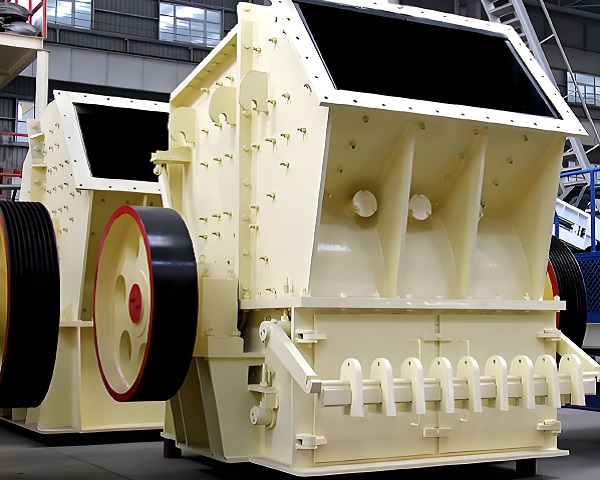

Product Picture Display of Hammer Crusher for Sale

FAQ about Hammer Crusher for Sale

>1. What materials are suitable for hammer crushers?

Hammer crushers are suitable for a variety of medium hardness and brittle materials. In the mining field, they can process metal ores such as iron ore and copper ore, as well as non-metallic ores such as limestone and dolomite, and crush large pieces of ore into suitable particle sizes for subsequent beneficiation processes. In the building materials industry, rocks such as granite and basalt can be crushed to prepare building sand and gravel aggregates. In the coal industry, raw coal can be crushed to meet the particle size requirements of processes such as coal washing and coking. In addition, brittle chemical raw materials such as gypsum and coke in the chemical industry can also be crushed. However, for materials with high hardness, high toughness or high viscosity, the crushing effect and efficiency will be affected.

>2. What is the working principle of the hammer crusher?

When the hammer crusher is working, the motor drives the rotor to rotate at high speed, and the hammer head installed on the rotor rotates rapidly. The material enters the crushing chamber from the feed inlet and is first strongly impacted by the high-speed rotating hammer head, just like a hammer hitting an object, causing the material to crack and initially crush. Then, the crushed materials fly out of the crushing chamber at high speed, collide with each other, and are further refined. At the same time, some materials will hit the impact plate of the crusher, rebound and be impacted by the hammer again, achieving secondary crushing. Finally, the materials that meet the particle size requirements are discharged through the gaps in the grate bars, while the materials with larger particle sizes continue to remain in the crushing chamber for crushing.

>3. What are the advantages of hammer crushers compared to other crushing equipment?

The advantages of hammer crushers are significant. It has a large crushing ratio and can crush large pieces of material into smaller particles at one time, reducing the subsequent crushing process. High production efficiency, high-speed rotating hammers and a variety of crushing methods combine to make the material crushing speed fast and the processing volume per unit time large. Low operating cost, simple structure, few parts, low manufacturing, installation and maintenance costs, and some models have reversible rotors to extend the life of the hammer and reduce the consumption of wearing parts. It has strong adaptability and can handle a variety of medium hardness and brittle materials, and is used in different industries.

>4. How to choose the right hammer crusher model?

Choosing the right model requires a comprehensive consideration of many factors. First, clarify the properties of the material to be crushed, including hardness, humidity, particle size, etc. Different materials have different requirements for equipment. For example, to crush high-hardness materials, you need to choose a model with strong crushing ability and good wear resistance. Then determine the production requirements, that is, the amount of material to be processed per hour (production capacity) and the desired output particle size. If the production volume is large and the output particle size is required to be fine, you must choose equipment of corresponding specifications. In addition, you must also consider the actual conditions such as the size of the installation site and the power supply to ensure that the equipment can be installed and operated normally.

>5. What should I do if the hammer head of the hammer crusher is worn?

When the hammer head of the hammer crusher is worn, you can use the characteristics of the reversible rotor of some models to reverse the rotor by changing the direction of the motor, so that the unworn side of the hammer head can participate in the crushing work and achieve uniform wear. If both sides of the hammer head are worn to a certain extent, it needs to be replaced. When replacing, first stop the machine and cut off the power supply. According to the steps in the equipment operation manual, disassemble the pin shaft and other parts that fix the hammer head, carefully remove the old hammer head, install the new hammer head, and ensure that it is firmly installed to prevent loosening during operation.

>6. How to adjust the discharge particle size of the hammer crusher?

Adjusting the discharge particle size of the hammer crusher is mainly achieved by replacing the grate bars of different specifications. The size of the gap between the grate bars determines the discharge particle size. If a smaller discharge particle size is required, replace the grate bars with smaller gaps, so that only materials with sufficiently small particle sizes can be discharged through the gaps. If a larger discharge particle size is required, replace the grate bars with larger gaps. When replacing the grate bars, ensure that the grate bars are firmly installed and accurately positioned to ensure the normal operation and discharge quality of the crusher, and avoid problems such as material blockage or uneven discharge particle size.

>7. What are the key points of daily maintenance of the hammer crusher?

Daily maintenance is very important. Regularly check the wear of vulnerable parts such as hammer heads and grate bars, and replace severely worn parts in time to prevent affecting the crushing effect and equipment safety. Pay attention to equipment lubrication, add lubricating oil to rotating parts such as rotor bearings at the prescribed time and method to ensure their flexible operation. Check whether the fasteners of the equipment, such as bolts and nuts, are loose. If they are loose, tighten them in time. It is also necessary to clean up the debris and accumulated materials in the crushing chamber to prevent blockage and affect the normal operation and crushing efficiency of the equipment.

>8. What are the precautions when installing the hammer crusher?

When installing the hammer crusher, choose a flat and solid foundation to ensure that the equipment is installed firmly and avoid excessive vibration during operation. Before installation, carefully check whether the various parts of the equipment are intact and whether they are damaged during transportation. According to the requirements of the equipment manual, correctly install the rotor, hammer head, grate bars and other components to ensure that their installation position is accurate and the connection is firm. After the installation is completed, a no-load test run should be carried out to check whether the equipment is running smoothly and whether there are abnormal sounds and vibrations. After confirmation, carry out the material operation to ensure the normal operation of the equipment.

>9. What factors affect the production efficiency of the hammer crusher?

The production efficiency is affected by many factors. In terms of material properties, materials with high hardness, high humidity and large particle size are difficult to crush, and the efficiency will be reduced. Equipment factors, such as rotor speed. The higher the speed, the greater the impact force of the hammer, and the higher the crushing efficiency. The right number and weight of hammers can also improve crushing efficiency. The technical level and operation method of the operator also have an impact, such as whether the feeding is uniform. Uneven feeding will lead to unstable equipment load and reduce efficiency. In addition, the maintenance of the equipment. Good maintenance can ensure the normal operation of the equipment and improve production efficiency.

>10. How to judge whether the hammer crusher is faulty?

It can be judged in many ways. Judging from the running sound, the sound is stable during normal operation. If there is an abnormal impact sound, friction sound or sharp noise, there may be problems such as loose parts, wear or damage. Observe the vibration of the equipment. If the vibration amplitude is too large or irregular, it may be caused by unbalanced rotors, loose foundations, etc. Check the discharge situation. If the discharge particle size is uneven, the output decreases, or there is a blockage, it may be caused by damaged grate bars, severe wear of the hammer, or uneven feeding. You can also judge whether the equipment is faulty by checking whether the temperature, current and other parameters of the equipment are abnormal.