A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

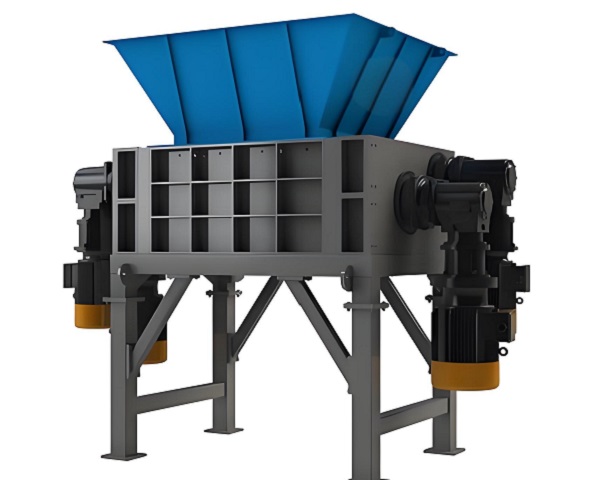

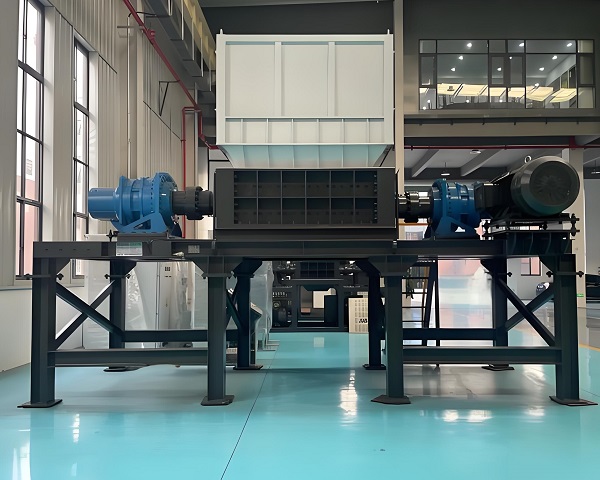

What is the Four Shaft Fhredder for Sale

The four shaft shredderr is a powerful and widely used crushing equipment, playing a key role in the field of resource recycling and processing.

Structurally, it has four carefully designed rotating blades, which cooperate with each other to form a complex and efficient crushing space. The blades are equipped with sharp and sturdy blades. Through high-speed rotation, the blades exert strong shearing, extrusion and tearing forces on the materials, quickly breaking the materials into small pieces. This unique multi-axis design greatly improves the crushing efficiency and effect, and can process various materials faster and more thoroughly than single-axis or double-axis shredders.

The application range of the four shaft shredderr is extremely wide. In the resource recycling industry, it is a good helper for processing scrap metal. Whether it is a scrapped car shell, a scrap home appliance shell, or metal scraps, the four shaft shredderr can break it into particles of suitable size, which is convenient for subsequent smelting and reprocessing, and realizes the recycling of metal resources. For plastic recycling, it also performs well, breaking waste plastic bottles, plastic films, plastic pipes, etc. into fine fragments, providing high-quality raw materials for plastic recycling granulation. In the field of wood processing, the four shaft shredderr can process wood scraps, waste furniture, branches, etc., and crush them into wood chips or fibrous materials for the production of artificial boards, papermaking or as raw materials for biomass energy.

The four shaft shredderr also plays an important role in the field of environmental protection. It can handle large waste in domestic garbage, such as old sofas, mattresses, etc., reduce the volume of garbage, and facilitate subsequent transportation and processing. When processing rubber products, such as waste tires, the four shaft shredderr can crush them into rubber particles for the production of environmentally friendly products such as rubber floor tiles and runways.

The four shaft shredderr also has the advantages of easy operation and convenient maintenance. Its control system has a high degree of intelligence, and the operator can easily set and adjust the operating parameters of the equipment. At the same time, the structural design of the equipment is reasonable, which is convenient for daily maintenance and reduces the cost of use. In short, the four shaft shredderr has made important contributions to resource recycling and environmental protection with its excellent performance and wide application.

Operating principle of Four Shaft Fhredder for Sale

The four shaft shredderr is a highly efficient material crushing equipment. Its working principle is based on the powerful shearing, squeezing and tearing forces generated by the coordinated movement of multiple axes to achieve the crushing of various materials.

Core components and movement mode

The four shaft shredderr is mainly composed of four parallel and independently rotating knife shafts, and a certain number and specifications of blades are evenly distributed on each knife shaft. These blades rotate at high speed driven by the knife shaft to form four rotating working surfaces. When working, the four knife shafts operate at a specific speed and direction. Usually, the two opposite knife shafts rotate in opposite directions, so that a strong relative movement is formed between adjacent knife shafts.

Generation of crushing force

When the material enters the crushing chamber of the four shaft shredderr, it will first be grabbed and hooked by the blades. Due to the special shape and arrangement of the blades, they are like sharp scissors, which perform preliminary cutting and tearing of the material. As the knife shaft continues to rotate, the material is constantly subjected to shear force between adjacent knife shafts. This shear force is generated by the relative movement between the blades, just like we use two scissors to cut paper against each other. The material is gradually divided into smaller pieces under the action of shear force.

At the same time, the knife shaft will also squeeze the material during the rotation process. The material is constantly squeezed in the narrow space formed by the four knife shafts, and its internal structure is damaged, the strength is reduced, and it is easier to be crushed. In addition, the tearing effect of the blade cannot be ignored. Some tough materials will be torn into smaller pieces under the pulling of the blade.

Material crushing process

The material is constantly sheared, squeezed and torn in the crushing chamber, and is gradually crushed into particles of the required size. The crushed material will be discharged from the discharge port at the bottom of the equipment. In actual operation, the size and shape of the crushed material can be controlled by adjusting the parameters such as the spacing of the blades and the rotation speed of the knife shaft to meet the needs of different users. For example, when it is necessary to crush finer particles, the spacing of the blades can be appropriately reduced or the rotation speed of the knife shaft can be reduced to increase the residence time of the material in the crushing chamber and the number of crushing times.

Advantages and features of Four Shaft Fhredder for Sale

As an advanced crushing equipment, the four shaft shredderr has shown significant advantages in many fields. The following is a summary of several key aspects.

1. Efficient crushing capacity

The four shaft shredderr is equipped with four independently rotating knife shafts. This multi-axis design greatly increases the contact area and crushing frequency with the material. Compared with single-axis or double-axis shredders, it can shear, squeeze and tear the material multiple times in a shorter time. For example, when processing scrap metal, ordinary double-axis shredders may take a long time to break large metal components into small pieces, while the four shaft shredderr can quickly decompose the metal with the synergy of multiple axes, greatly improving production efficiency and significantly increasing the amount of material processed per unit time.

2. Wide range of applicable materials

It has strong adaptability to materials and can handle a variety of types of materials. Whether it is hard metal waste, such as scrapped car shells, scrap steel components, or soft plastic products, such as plastic bottles, plastic films, or tough rubber materials, such as scrap tires, the four shaft shredderr can handle them efficiently. It breaks the limitations of traditional equipment on material types and provides flexible crushing solutions for different industries.

3. Controllable crushing particle size

Users can accurately control the particle size of the crushed material by adjusting parameters such as blade spacing and knife shaft speed according to actual needs. If you need to produce fine metal particles for recycling and smelting, you only need to adjust the relevant parameters, and the four shaft shredderr can crush the material into a uniform specified particle size. This flexibility enables the four shaft shredderr to meet the diverse needs of different industries for material particle size, whether it is the pretreatment of raw materials in the resource recycling industry or the refinement of raw materials in the biomass energy field.

4. Stable and reliable operation

The four shaft shredderr has a reasonable structural design, and the knife shaft and blades are carefully selected and processed with high strength and wear resistance. It can still maintain stable performance under long-term high-load operation. Its transmission system uses high-quality components to ensure that the knife shaft rotates smoothly and reduces vibration and noise. At the same time, the equipment is equipped with a complete overload protection device. When encountering unbreakable hard objects or too much material, it can automatically stop for protection to avoid equipment damage and extend the service life of the equipment.

5. Easy operation and maintenance

The equipment adopts an intelligent control system with a simple and easy-to-understand operation interface. Operators can get started after simple training. In terms of daily maintenance, operations such as blade replacement are relatively simple. The equipment structure is reasonably designed, which is convenient for cleaning internal residual materials and checking the operating status of each component, reducing maintenance costs and time costs.

Technical Parameter Table of Four Shaft Fhredder for Sale

| Parameter | Unit | FS-600 | FS-800 | FS-1000 | FS-1200 | FS-1500 | FS-1800 |

|---|---|---|---|---|---|---|---|

| Shredding Chamber Size | mm | 600×600 | 800×800 | 1000×1000 | 1200×1000 | 1500×1200 | 1800×1200 |

| Main Shaft Power (Dual Motor) | kW | 2×11 | 2×15 | 2×22 | 2×30 | 2×37 | 2×45 |

| Auxiliary Shaft Power (Dual Motor) | kW | 2×7.5 | 2×11 | 2×15 | 2×22 | 2×30 | 2×37 |

| Main Shaft Speed | rpm | 15–25 | 15–25 | 10–20 | 10–20 | 8–18 | 8–18 |

| Auxiliary Shaft Speed | rpm | 25–40 | 25–40 | 20–35 | 20–35 | 18–30 | 18–30 |

| Main Shaft Diameter | mm | Φ180 | Φ220 | Φ280 | Φ320 | Φ360 | Φ400 |

| Number of Blades | pcs | 32–40 | 40–48 | 48–60 | 60–72 | 72–84 | 84–96 |

| Blade Thickness | mm | 20–40 | 20–50 | 30–60 | 30–60 | 40–70 | 40–70 |

| Blade Material | — | 9CrSi / SKD-11 | SKD-11 / D2 | D2 / Cr12MoV | Cr12MoV | Cr12MoV | Cr12MoV |

| Screen Hole Size | mm | 20–60 | 20–80 | 30–100 | 40–120 | 50–150 | 50–150 |

| Discharge Size Range | mm | 20–60 | 20–80 | 30–100 | 40–120 | 50–150 | 50–150 |

| Capacity | t/h | 0.5–2.0 | 1.0–3.0 | 2.0–5.0 | 3.0–8.0 | 4.0–10.0 | 5.0–15.0 |

| Machine Weight | t | 2.0 | 3.5 | 5.5 | 8.0 | 10.5 | 13.0 |

| Control System | — | PLC Control | PLC + Touch Screen | Siemens PLC | Siemens PLC | Smart Control System | Smart Control System |

| Feeding Method | — | Manual / Conveyor | Conveyor | Conveyor / Hydraulic Pusher | Conveyor / Hopper | Automatic Feeding | Automatic Feeding |

| Applicable Materials | — | Plastic, Fabric, E-waste | Light Metal, Tires, Barrels | Industrial Waste, Pallets | Appliance Shells, Mixed Waste | Bulk Waste, Packaging | Hazardous Waste, Used Electronics |

If you have any special requirements, we will customize according to your special needs.

Product Picture Display of Four Shaft Fhredder for Sale

FAQ about Four Shaft Fhredder for Sale

>1. What are the advantages of a four shaft shredder over a two-axis shredder?

Compared with a two-axis shredder, a four shaft shredder has stronger cutting ability and higher crushing efficiency. The four blade shafts work together to achieve multi-angle shearing of materials and more uniform particle output, which is especially suitable for industrial waste processing with high hardness, complex structure or high-precision control of the output size.

>2. What types of materials are suitable for a four shaft shredder?

The four shaft shredder is suitable for a variety of difficult-to-handle solid waste materials, such as electronic waste (circuit boards, cables), light metals, plastic barrels, large pieces of garbage, industrial scraps, wooden pallets, waste home appliance casings and some hazardous waste. Its multi-axis structure helps to handle entangled, hard and irregularly shaped materials.

>3. Is the output particle size of the four shaft shredder adjustable?

Yes, the four shaft shredder is generally equipped with a screen system, and screens of different apertures can be replaced according to needs to control the output size range. By adjusting the gap between the screen and the blade, the particle size of the output material can be controlled between 20mm and 150mm to meet the needs of different processing links.

>4. Is the maintenance of the four shaft shredder difficult?

Although the structure of the four shaft shredder is complex, the design is usually easy to maintain. For example, the modular design of the tool, the automatic lubrication system, and the easy-to-remove screen can effectively reduce the maintenance intensity. Regular inspection of bearings, tool wear and electronic control systems can keep the equipment running stably for a long time.

>5. Will the tool material affect the service life?

Yes, the tool material has a significant impact on the shredding effect and life. The commonly used tool materials for four shaft shredders are 9CrSi, SKD-11, D2, Cr12MoV, etc. Among them, high-alloy tool steel has high hardness and high wear resistance, which is suitable for continuous operation and processing of metal or high-hardness materials.

>6. Is the power and energy consumption of the four shaft shredder high?

The four shaft shredder is usually equipped with 4 motors, and the total power ranges from tens to hundreds of kilowatts depending on the model. Although the energy consumption is high, its high-efficiency crushing capacity and labor cost saving can bring higher benefits in the overall operation, which is suitable for large-scale and heavy-load operation scenarios.

>7. Does the four shaft shredder have an overload protection function?

Most modern four shaft shredders are equipped with intelligent PLC control systems, with built-in overload protection, automatic reversal, material blocking shutdown alarm and other functions, which effectively protect the motor and knife shaft, avoid equipment failure due to overload, foreign matter, etc., and improve the safety and continuity of use.

>8. Is the four shaft shredder suitable for continuous operation?

Yes, the four shaft shredder is designed for industrial heavy-duty applications and supports long-term continuous operation. Reasonable cooling system, automatic lubrication and high-strength materials ensure the high durability and thermal stability of the equipment, which is suitable for continuous processing of large amounts of solid waste on the production line.

>9. What auxiliary equipment is needed to install a four shaft shredder?

Typical configurations include feeding system (conveyor belt or silo), discharging system (belt conveyor, spiral conveyor), dust removal system (pulse dust collector), electric control cabinet (PLC or remote control), etc., which can be customized according to working conditions to achieve automated and continuous operation.

>10. How long is the service life of a four shaft shredder?

The service life of a four shaft shredder depends on the frequency of use, material type and maintenance status. Generally, high-quality equipment can last for 8-12 years under normal use and maintenance, and the tool replacement cycle ranges from several months to one year, which can continuously provide high-performance crushing capabilities.