A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

What is the Waste Flip Flow Screen

The waste flip flow screen is a high-efficiency screening equipment designed for complex materials such as urban domestic waste, construction waste, and industrial solid waste. It is a type of elastic vibrating screen. It effectively screens wet, sticky, lightweight, and diversified garbage materials through high-frequency vibration and elastic dislocation movement of the screen, solving the problems of blockage and low efficiency of traditional screening equipment in garbage disposal.

Garbage screening has the characteristics of different particle sizes, complex components, high moisture content, and easy entanglement. Conventional circular vibrating screens, drum screens, and linear screens are often unable to cope with it. The waste flip flow screen adopts a dual-vibration source structure. The screen frame and the screen are driven by different power sources, forming a composite vibration with different frequencies and dislocations in direction, so that the elastic mesh belt on the screen is continuously stretched and relaxed, producing a "jumping" movement. This dynamic screening method can not only enhance the separation effect of materials, but also continuously remove wet mud and entanglements that block the screen holes, achieving efficient self-cleaning.

The screen of the waste flip flow screen is usually made of polyurethane elastic material or high wear-resistant rubber. It has good elasticity, wear resistance and tear resistance, can withstand continuous high-frequency vibration, and adapt to harsh working conditions with high humidity and high corrosion. The modular structure of the screen makes replacement easy and maintenance cost low.

In the urban solid waste treatment production line, the relaxation screen can be used for coarse and fine classification of domestic waste, pre-treatment of RDF (refuse-derived fuel) sorting, separation of plastics and organic matter, etc. It is also often used in conjunction with air separators, magnetic separators, optical separators and other equipment to form a complete garbage sorting system. The screening particle size range is usually 10 to 80 mm, which can be adjusted according to the screen configuration.

The waste flip flow screen has the characteristics of compact structure, small footprint, low energy consumption and low operating noise. It is suitable for deployment in small and medium-sized garbage treatment plants, sorting centers and resource utilization workshops. It not only improves the efficiency of garbage screening and resource recovery rate, but also significantly reduces the subsequent processing load.

The waste flip flow screen is a high-efficiency equipment developed to solve the problem of screening complex garbage materials. It has become an indispensable and important part of the modern solid waste treatment system, providing a key guarantee for the realization of garbage resource utilization, reduction and harmless treatment.

Operating principle of Waste Flip Flow Screen

The core working principle of the waste flip flow screen is based on the two key technologies of "dual-mass vibration system" and "elastic screen dynamic dislocation vibration". The equipment is usually composed of a screen box, an excitation device, an elastic screen system, a transmission system and a shock-absorbing support. Its biggest feature is that during the vibration process, the screen body and the screen generate vibrations of different frequencies and amplitudes, forming a unique "relaxation" movement mode, which effectively copes with the problem of wet and sticky garbage screening.

During operation, the two exciters drive the screen box and the tensioning beam respectively. The screen box acts as the main vibration system to vibrate at a low frequency and a large amplitude, while the elastic beams tensioned at both ends of the screen vibrate at a high frequency and a small amplitude. Due to the phase difference between the two systems, the screen produces periodic stretching (tension) and retraction (relaxation) movements under the basic vibration of the screen box. This continuous expansion and contraction causes the screen to form a wave-like jumping deformation, thereby driving the material to produce a strong throwing motion.

In the process of screening garbage, this dynamic "flipping" can not only effectively break up the material clumps and disperse them, but also significantly prevent wet and sticky materials from clogging the screen holes. The retention time of the material on the screen becomes shorter, and the probability of passing through the screen hole increases, thereby improving the screening efficiency and the output under the screen. At the same time, the lightweight material produces friction and peeling between the screen during the throwing process, further achieving a better sorting effect.

The screen of the waste flip flow screen is made of polyurethane or rubber material, which has excellent flexibility and tear resistance, and can work stably for a long time under high-frequency tension. The screen structure is usually modular in design, and the two ends are fixed to the vibrating beam through a tensioning device. Moderate tension can ensure that the screen is fully deformed during vibration to avoid fatigue fracture.

The entire screening process does not require additional cleaning devices because the continuous shaking of the screen itself has a self-cleaning function. Even in the face of high-moisture and high-viscosity materials such as wet domestic garbage, kitchen garbage, and construction waste with high organic content, the relaxation screen can maintain stable and efficient operation. Compared with traditional circular vibration screens and drum screens, this principle shows extremely strong reliability and adaptability in garbage disposal applications.

The working principle of the waste flip flow screen fully combines the mechanical vibration and elastic dynamics characteristics, and realizes the high-frequency bouncing of the screen through the dual vibration source staggered drive, which fundamentally solves the technical bottlenecks such as "blocking, sticking, clumping, and entanglement" in garbage screening. It is a key screening equipment in the current solid waste resource treatment system.

Advantages and features of Waste Flip Flow Screen

Waste Flip-flow Screen is an efficient screening equipment designed for complex materials with high moisture, high viscosity and many impurities such as municipal solid waste, construction waste and industrial solid waste. Compared with traditional vibrating screens or drum screens, Waste Flip-flow Screen has significant structural advantages and operating characteristics, and can effectively deal with common problems such as screen hole blockage, low screening efficiency and frequent maintenance in the garbage sorting process.

Waste Flip-flow Screen adopts the principle of dual-source excitation. The screen frame and the elastic screen form a staggered amplitude, which makes the screen produce high-frequency stretching and relaxation movement (similar to jumping), so that the material jumps on the screen surface. This dynamic self-cleaning screening method is particularly suitable for municipal solid waste and construction waste with high moisture content, strong adhesion and complex impurities. Even in the face of "difficult to screen" impurities such as wet plastic bags, residual organic matter, concrete fragments, etc., the relaxation screen can still maintain smooth screening, greatly reducing the frequency of screen hole blockage.

The screen of Waste Flip-flow Screen is generally made of polyurethane or high-elastic rubber, with good wear resistance and elasticity, and the structure is modular, easy to replace and low cost. Since the material composition in the garbage varies greatly, the diversity and easy replacement of the screen can effectively improve the flexibility and continuous working ability of the screening system.

In terms of performance, the screening accuracy of Waste Flip-flow Screen is much higher than that of traditional equipment, and it is particularly suitable for the separation of fine-grained garbage in the range of 0.5mm-50mm, such as soil, organic matter, plastic fragments, etc. Its screening efficiency can reach more than 90%, and it plays an irreplaceable role in process links such as resource utilization of construction waste, pretreatment of urban solid waste, and preparation of RDF fuel.

Waste Flip-flow Screen runs smoothly, has low noise, and has a long maintenance cycle, and is suitable for 24-hour continuous work. Its amplitude is adjustable to adapt to different material characteristics and production needs, and it shows excellent stability and economy in solid waste treatment projects with large processing volume and high requirements.

Waste Flip-flow Screen has outstanding advantages such as advanced structure, strong self-cleaning ability, high screening efficiency, wide adaptability and easy maintenance. It is one of the key equipment in the current solid waste resource treatment and green sorting system. With the development of the environmental protection industry, its application in the field of garbage treatment will become more and more extensive.

Technical Parameter Table of Waste Flip Flow Screen

| Model | Screen Deck Size (mm) | Number of Decks | Screen Aperture (mm) | Capacity (t/h) | Vibration Frequency (Hz) | Motor Power (kW) | Dimensions (mm) |

|---|---|---|---|---|---|---|---|

| WFFS1530 | 1500 × 3000 | 1 | 1–50 | 10–80 | 15–25 | 15 | 3900 × 2200 × 1800 |

| WFFS1836 | 1800 × 3600 | 1 | 1–50 | 30–120 | 15–25 | 18.5 | 4500 × 2500 × 2000 |

| WFFS2060 | 2000 × 6000 | 1 or 2 | 1–50 | 80–200 | 16–24 | 22 | 6800 × 2900 × 2300 |

| WFFS2460 | 2400 × 6000 | 1 or 2 | 1–50 | 100–280 | 16–24 | 30 | 7000 × 3200 × 2500 |

| WFFS3060 | 3000 × 6000 | 1 or 2 | 2–60 | 150–350 | 16–22 | 37 | 7200 × 3700 × 2600 |

If you have any special requirements, we will customize according to your special needs.

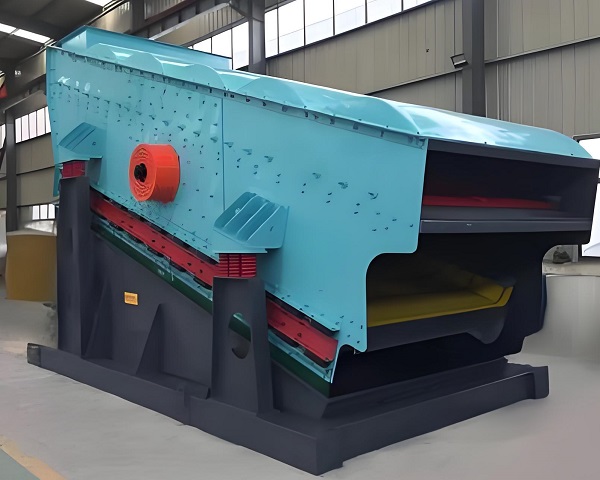

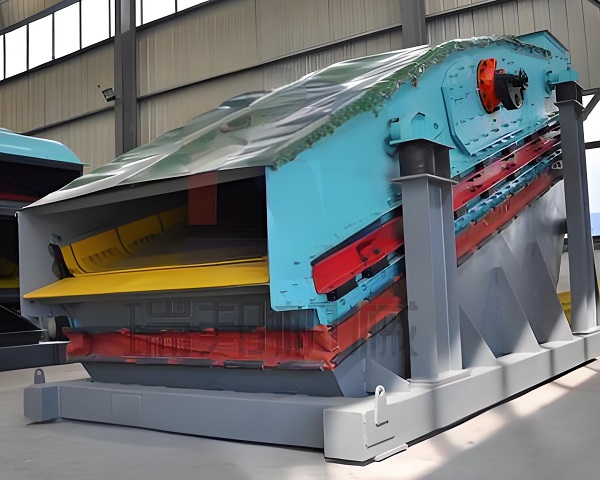

Product Picture Display of Waste Flip Flow Screen

FAQ about Waste Flip Flow Screen

>Which waste is Waste Flip Flow Screen suitable for?

It is suitable for municipal solid waste, industrial waste, construction waste, kitchen waste, etc. It is especially good at handling wet, sticky or complex materials, and plays an important role in material sorting and resource utilization.

>Compared with traditional screening equipment, what are the advantages of Waste Flip Flow Screen?

Its advantages are high screening efficiency and large processing capacity. The anti-clogging performance significantly reduces the cleaning frequency. The elastic screen plate is wear-resistan and has a long life. It has lower energy consumption and can flexibly adapt to different waste characteristics. The comprehensive cost advantage is obvious.

>What are the characteristics of the screen plate material of Waste Flip Flow Screen?

It is usually made of polyurethane or rubber, which has the characteristics of high elasticity, wear resistance and corrosion resistance. The screen hole size can be customized, and it can produce elastic deformation during vibration, effectively preventing waste adhesion and ensuring the screening effect.

>How to adjust the screening effect of Waste Flip Flow Screen?

By adjusting the frequency and amplitude of the main and secondary vibration motors, as well as changing the tension and inclination angle of the screen plate, the particle size, humidity and composition of different wastes can be adapted, and the screening efficiency and classification accuracy can be accurately controlled.

>Is the maintenance cost of Waste Flip Flow Screen high?

The maintenance cost is low. Since the screen plate has strong wear resistance and long service life, and the self-cleaning function reduces blockage, the frequency of cleaning and replacement is reduced; in addition, the equipment structure is stable, and only the status of the vibration components and the screen plate needs to be checked daily to reduce maintenance workload.

>What is the processing capacity of this equipment?

Compared with traditional screening equipment, the processing capacity of Waste Flip Flow Screen can be increased by 30% - 50%. The processing capacity of a single device per hour varies depending on the model, and large-scale equipment can process tens to hundreds of tons of waste per hour.

>What contributions does Waste Flip Flow Screen make to environmental protection?

Through efficient screening, it helps to separate recyclable resources from waste and improve resource recovery rate; low operating noise, low energy consumption, reduced pollution emissions, meet environmental protection requirements, and promote the green development of solid waste treatment.

>Is the equipment installation complicated? Does it require a special foundation?

The equipment is relatively easy to install. Generally, a solid concrete foundation is required to support the vibration load during operation. The manufacturer usually provides installation instructions to ensure that the equipment is installed horizontally and the vibration and drive components are correctly connected.

>What problems may be encountered when using Waste Flip Flow Screen?

You may encounter problems such as vibration motor failure, partial damage or elastic attenuation of the screen plate, and material overload leading to reduced screening efficiency. Regular inspection and maintenance are required to deal with abnormal situations in a timely manner.

>What is the minimum and maximum particle size that the Waste Flip Flow Screen can handle?

The sieve hole size can be customized, with a minimum of 3mm, suitable for fine screening; the maximum can be up to 100mm, which meets the initial separation requirements of large particle waste, and is adjusted according to the actual application scenario.

>What is the energy consumption level of the equipment?

The dual vibration system design optimizes energy transfer, reducing energy consumption by 20% - 30% compared to traditional equipment. By accurately controlling vibration parameters, it reduces unnecessary energy consumption while ensuring processing efficiency.

>How long is the service life of Waste Flip Flow Screen?

Under normal use and maintenance, the service life of the whole machine can reach 8-10 years, and the replacement cycle of the screen plate is about 1-3 years (depending on the working conditions). Regular maintenance can extend the service life of the equipment and components.

>Which industries will use Waste Flip Flow Screen?

It is mainly used in municipal solid waste treatment, industrial waste recycling, construction waste recycling, food processing waste treatment, resource recycling and other industries. It is a key equipment for achieving waste reduction and resource utilization.