A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

What is the Flip Flow Screen for Sale

Flip Flow Screen is a high-efficiency screening device designed for handling wet, sticky, and easily blocked materials. Compared with traditional circular vibrating screens or linear vibrating screens, Flip Flow Screen uses the principle of coordinated vibration of dual vibration sources and elastic screen systems to make the screen produce a wave-like dynamic similar to "jumping", thereby achieving the effect of self-cleaning and efficient screening.

The core feature of this equipment lies in its unique screen structure. The screen is made of high-strength elastic material and is installed on a tensioning frame made of rubber or polyurethane. The tensioning frame and the screen body form a two-degree-of-freedom system through a connecting rod. When the exciter vibrates, the screen body and the screen will vibrate at different frequencies and directions, causing the screen to continuously "flip" and "swing", effectively preventing the screen holes from being blocked. At the same time, the jumping movement of the material on the screen surface also enhances the separation between particles, greatly improving the screening efficiency.

Flip Flow Screen is usually used to screen materials with fine particle size (such as 0.1mm-10mm), high water content or high clay content. It is widely used in coal, urban garbage, construction waste, metallurgical slag, chemical industry and other industries. For example, in wet coal slime, refuse-derived fuel (RDF), asphalt recycling and other working conditions, Flip Flow Screen can show performance far exceeding that of traditional screening equipment.

The equipment is stable, low noise and easy to maintain. Because the screen is modularly designed, it can be replaced quickly after damage without dismantling the entire equipment.

Flip Flow Screen is an ideal equipment for solving difficult screening conditions, especially for fine particles and wet sticky materials that cannot be effectively processed by conventional screening methods. Its advantages of high efficiency, self-cleaning and low energy consumption are being recognized and adopted by more and more industrial fields.

Operating principle of Flip Flow Screen for Sale

Core working principle: double-mass relaxation motion

The core principle of Flip flow screen is to use the "relaxation effect" generated by the double-mass vibration system. The equipment mainly consists of a fixed frame and a movable screen box, which are connected by elastic elements (such as rubber springs and metal springs). The specific movement process is as follows:

1. Excitation source drive:

The vibration motor or exciter drives the fixed frame to generate high-frequency vibration (the vibration frequency is usually 10~15Hz), and at the same time transmits the vibration to the movable screen box through the elastic element.

2. Asynchronous motion produces relaxation effect:

The vibration directions of the fixed frame and the movable screen box are opposite and asynchronous, resulting in periodic tension and relaxation deformation of the flexible screen surface (such as rubber screen plate, polyurethane screen mesh) installed between the two.

When the fixed frame moves upward and the movable screen box moves downward, the screen surface is stretched (tension state); conversely, when the fixed frame moves downward and the movable screen box moves upward, the screen surface shrinks (relaxation state).

This "relaxation" movement causes the screen surface to deform with large amplitude and high acceleration (up to 20~30g), forming a high-frequency impact effect similar to "waves".

3. Material screening process:

After wet and sticky materials enter the screen surface, they undergo the following process under the action of relaxation movement:

Particle dispersion: The high-frequency deformation of the screen surface destroys the material agglomerates and separates the bonded particles from each other.

Improved screening efficiency: When the screen surface is tensioned, the screen holes are stretched and expanded to promote the screening of fine particles; when relaxed, the screen surface shrinks and squeezes the material, further pushing the particles through the screen holes, and at the same time, the particles blocked in the screen holes are removed through the elastic deformation of the screen surface.

Self-cleaning function: The periodic deformation of the screen surface can effectively prevent the material from adhering to the screen and reduce the clogging phenomenon. It is especially suitable for processing sticky materials with a moisture content of up to 25%~30% (such as coal slime, wet mineral powder).

Key structural design and motion characteristics

1. The role of the flexible screen surface:

Flip flow screen uses a screen surface made of elastic materials such as rubber and polyurethane instead of traditional metal screens. The elastic deformation ability of the flexible screen surface is the core of achieving relaxation and tension movement. Its advantages include: Wear resistance and impact resistance, suitable for processing high-hardness and highly corrosive materials; The shear force generated during the deformation process can effectively disperse viscous materials and avoid agglomeration.

2. Dynamic characteristics of the dual-mass vibration system: The fixed frame and the movable screen box form a dual-degree-of-freedom vibration system through elastic elements. The mass, stiffness and damping of the two must be accurately matched to ensure the stability of asynchronous motion. By adjusting the frequency and phase of the exciting force, the system can be put into a resonant state, maximizing the relaxation effect and improving the screening efficiency.

3. Low frequency and large amplitude characteristics: Compared with the "high frequency and small amplitude" mode of traditional vibrating screens, Flip flow screen adopts "low frequency and large amplitude" (amplitude can reach 8~15mm), which can produce stronger material impact and dispersion effects with the deformation of the screen surface, especially suitable for processing wet materials with a wide range of particle sizes (such as 0~50mm).

Advantages and features of Flip Flow Screen for Sale

Flip Flow Screen is a highly efficient screening equipment, widely used in material grading operations in mining, coal, building materials, metallurgy and other industries. Its unique working principle and structural design make it show significant advantages in handling wet, sticky and fine-grained materials. The following is a detailed analysis of its core features and advantages:

Working principle and structural innovation of Flip Flow Screen

The core principle of Flip Flow Screen is to achieve screening through a dual-mass vibration system. The screen box and the relaxation screen plate are supported by two sets of springs respectively. The main vibration motor drives the screen box to produce linear vibration, while the auxiliary vibration device drives the relaxation screen plate to vibrate at a high frequency and small amplitude, so that the screen plate produces periodic relaxation and tension movement. This composite motion mode of "screen box vibration + screen plate relaxation" breaks the limitation of traditional screening equipment relying on single vibration, and is especially suitable for handling high-humidity and high-viscosity materials (such as coal slime, wet sand, clay, etc.) that ordinary vibrating screens are difficult to deal with.

The core features of Flip Flow Screen

1. High-efficiency anti-blocking screen plate design

The screen plate of Flip Flow Screen is made of elastic polyurethane material and is designed to have an alternating "tension-relaxation" movement mode. When the screen plate is relaxed, the surface will produce elastic deformation, and the wet material adhering to the screen hole will fall off due to the deformation of the screen plate, which fundamentally solves the problem of easy blockage of traditional metal screens. For example, when processing coal slime with a moisture content of more than 25%, the blockage rate of traditional vibrating screens can reach more than 30%, while the blockage rate of Flip Flow Screen can be controlled within 5%.

2. High screening efficiency and processing capacity

The composite vibration mode causes the material to produce a complex motion trajectory of throwing, sliding, and flipping on the screen surface, so that the material particles can contact the screen holes more fully, and the probability of fine particles passing through the screen is significantly increased. Under the same specifications, the processing capacity of Flip Flow Screen is 30%~50% higher than that of traditional vibrating screens, and the screening efficiency can reach more than 90% (traditional screens are generally 70%~80%).

3. Low energy consumption and long life

The dual-mass vibration system reduces the impact on the frame through spring shock absorption, and the energy consumption of the whole machine is 20%~30% lower than that of traditional screens.

The wear resistance of the polyurethane screen plate is 3~5 times that of the metal screen, and it is easy to replace, and the maintenance cost is reduced by about 40%.

4. Flexible and adjustable screening parameters

By adjusting the frequency and phase difference of the main and auxiliary vibration motors, the relaxation amplitude and vibration intensity of the screen plate can be flexibly changed to meet the screening needs of materials with different particle sizes (coarse particles can reach 100mm, fine particles can reach 0.2mm) and humidity, and the equipment has strong versatility.

Application scenario advantages of Flip Flow Screen

1. Screening problems of wet fine particles

In the coal washing industry, traditional vibrating screens are prone to blockage of the screen holes due to the adhesion of moisture and fine mud when processing coal slime, and frequent shutdowns are required for cleaning. The anti-blocking characteristics of Flip Flow Screen can realize continuous operation, reduce downtime, and improve production line efficiency. For example, after a coal preparation plant introduced Flip Flow Screen, the coal slurry screening efficiency increased from 65% to 88%, and the annual processing capacity increased by about 200,000 tons.

2. Fine classification of high value-added materials

In the beneficiation process of gold and rare metal mines, Flip Flow Screen can efficiently classify fine-grained slurry to avoid the loss of precious metals caused by blockage in traditional screening. Its screening accuracy can reach 0.074mm (200 mesh), which meets the needs of fine beneficiation.

3. Environmental protection and energy-saving advantages

The low noise design of the elastic screen plate (noise ≤85dB) meets environmental protection requirements and reduces industrial noise pollution.

The characteristics of low energy consumption and low maintenance are in line with the goal of green mine construction, especially suitable for areas with strict requirements on energy consumption and environmental protection.

With its high anti-blocking efficiency, energy-saving and durable, and strong adaptability, Flip Flow Screen has become a revolutionary equipment in the field of wet fine-grained material screening. As the requirements for screening efficiency and refinement in industries such as mining and environmental protection increase, the application prospects of Flip Flow Screen will be broader, especially in resource recovery, solid-liquid separation and other subdivided scenarios, where its technical advantages will be further highlighted. Choosing Flip Flow Screen can not only improve production efficiency, but also reduce overall costs, making it an ideal choice for modern industrial screening upgrades.

Technical Parameter Table of Flip Flow Screen for Sale

| Model | Screen Deck Size (mm) | Number of Decks | Screen Aperture (mm) | Capacity (t/h) | Vibration Frequency (Hz) | Motor Power (kW) | Dimensions (mm) |

|---|---|---|---|---|---|---|---|

| FFS1230 | 1200 × 3000 | 1 | 1–30 | 10–80 | 15–25 | 11 | 3600 × 2000 × 1800 |

| FFS1536 | 1500 × 3600 | 1 | 1–30 | 30–120 | 15–25 | 15 | 4200 × 2300 × 2000 |

| FFS1836 | 1800 × 3600 | 1 or 2 | 1–30 | 50–160 | 16–24 | 18.5 | 4400 × 2600 × 2100 |

| FFS2060 | 2000 × 6000 | 1 or 2 | 1–30 | 80–250 | 16–24 | 22 | 6800 × 2900 × 2300 |

| FFS2460 | 2400 × 6000 | 1 or 2 | 1–30 | 100–320 | 16–24 | 30 | 7000 × 3200 × 2500 |

If you have any special requirements, we will customize according to your special needs.

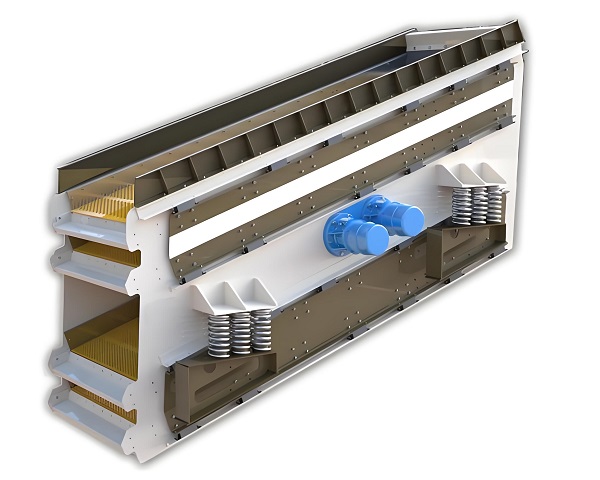

Product Picture Display of Flip Flow Screen for Sale

FAQ about Flip Flow Screen for Sale

>1. Is the screen hole of Flip flow screen replaceable?

Yes, the Flip flow screen has a modular structure. Modules with different screen hole sizes can be freely replaced according to the screening requirements, which greatly enhances the adaptability and flexibility of the equipment.

>2. What are the common models of Flip flow screen?

Common models include FFS1230, FFS1536, FFS1836, FFS2060, FFS2460, etc. The models are usually named after the screen surface size. The appropriate specifications can be selected according to the output and material properties.

>3. In which industries is Flip flow screen mainly used?

Flip flow screen is widely used in coal, mining, construction waste, urban solid waste, metallurgy, sand and gravel, cement, chemical industry and other industries, especially suitable for screening materials with high water content and easy to clog.

>4. Compared with ordinary vibrating screens, what are the advantages of Flip flow screen?

Its main advantages include: high screening efficiency, strong self-cleaning ability, not easy to block holes, can screen fine wet materials, low vibration noise, long service life, and is an ideal equipment for handling difficult screening tasks.

>5. How fine is the material suitable for Flip flow screen to screen?

Flip flow screen is suitable for materials in the range of 1mm-50mm, especially in the screening of wet and sticky fine particles of 0.1mm-10mm, which is far superior to conventional screening equipment.

>6. What are the common materials for the screen of Flip flow screen?

Flip flow screen usually uses elastic screen made of polyurethane (PU) or rubber. These materials are wear-resistant, elastic, and have long service life, and can effectively withstand high-frequency stretching.

>7. Is the screen of Flip flow screen easy to damage?

Due to the modular design and high-quality elastic materials, the screen has high durability. Even if it is partially damaged, some modules can be quickly replaced without replacing the screen as a whole, which is convenient for maintenance.

>8. What is the processing capacity of Flip flow screen?

The processing capacity depends on the model, material characteristics and screen size, and generally ranges from 10-400 tons/hour. Heavy-duty models can achieve higher production capacity.

>9. Is the operation noise of Flip flow screen loud?

The operation noise of Flip flow screen is relatively low, mainly because the screen body and screen mesh are flexibly connected, and the vibration transmission is reduced by the shock-absorbing device, which is suitable for factory environments with high environmental protection requirements.

>10. Does Flip flow screen support multi-layer screening?

Some Flip flow screen models support double-layer structure, which can achieve coarse and fine classification at the same time, improve screening efficiency and space utilization, but single-layer structure is used in most working conditions to ensure the screening rate.

>11. Is Flip flow screen energy-saving?

Compared with traditional vibrating screens, its motor power is moderate, but due to its high screening efficiency and large processing capacity, its unit energy consumption is lower, and it has a good energy-saving effect.

>12. How to maintain Flip flow screen?

The main maintenance contents include regular inspection of screen tension, exciter lubrication, bolt tightening and rubber component wear. Due to the simple structural design, the maintenance cycle is long and the workload is small.

>13. What are the requirements for the installation foundation of Flip flow screen?

Due to the small vibration, the requirements for the foundation of Flip flow screen are relatively low, but it needs to be kept horizontal and stable, and equipped with shock pads or shock absorber frames to improve the operation stability and extend the service life.