A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

What is the Shaftless Screw Conveyor

The shaftless screw conveyor is a highly efficient material conveying equipment. With its unique structural design and excellent performance, it plays a key role in many industries. Its main body consists of a U-shaped or semicircular trough, a spiral blade without a central shaft, a drive device and an inlet and outlet. Different from the traditional shafted screw conveyor, it welds the spiral blade directly on the hollow tube or mandrel, completely eliminating the material entanglement problem that may be caused by the central shaft.

During operation, the drive device drives the shaftless screw body to rotate at high speed, and the thrust generated by the spiral blade pushes the material to move along the axial direction of the trough until it is discharged from the outlet. This design makes it have significant advantages in conveying materials with high viscosity and high fiber content, such as sludge in municipal sewage treatment, kitchen waste in domestic waste treatment, and straw in the agricultural field. At the same time, the small gap design between the spiral blade and the inner wall of the trough body can not only ensure the smooth transportation of materials, but also prevent accumulation and blockage.

In terms of performance, the shaftless screw conveyor can be flexibly customized according to the characteristics of the material and the conveying requirements. By adjusting the pitch and diameter of the spiral blades, the conveying efficiency can be effectively improved. The variable pitch design is suitable for materials with poor fluidity and can achieve compression conveying; increasing the blade diameter can meet the needs of long-distance conveying. In addition, the fully enclosed tank body gives it good sealing performance, avoiding dust and leakage of materials, protecting the quality of materials and optimizing the working environment.

With these advantages, shaftless screw conveyors are widely used in municipal environmental protection, food processing, agriculture and other fields. The municipal industry is used for sludge and garbage transportation; the food industry transports fruit and vegetable waste and meat scraps; the agricultural field is responsible for the transportation of poultry and livestock manure and straw. In addition, by adding flushing, anti-blocking monitoring and other devices, the reliability and automation of the equipment are further improved, providing a stable and efficient solution for material transportation in various industries.

Operating principle of Shaftless Screw Conveyor

The working principle of the shaftless screw conveyor is based on a unique structural design and mechanical transmission. Its main body consists of a U-shaped or semicircular trough, a spiral blade without a central shaft, a drive device and an inlet and outlet. The spiral blade without a central shaft is the core component. It is directly welded on a hollow tube or a spiral mandrel, eliminating the material entanglement problem caused by the central shaft of the traditional shafted screw conveyor.

When the equipment is running, the drive device drives the shaftless screw body to rotate at high speed, and the thrust generated by the rotation of the spiral blade becomes the power source for material transportation. When the material enters the trough from the feed inlet, it moves toward the outlet along the axial direction of the trough under the continuous push of the spiral blade. Since there is no obstruction of the central shaft, materials with high viscosity, high fiber content and easy entanglement, such as sludge, domestic garbage, and kitchen waste, can also be smoothly transported to avoid blockage.

During the conveying process, the spiral blade maintains a small gap with the inner wall of the trough. This design ensures that the material can be effectively pushed forward and will not accumulate in the gap. At the same time, in order to adapt to different material characteristics and conveying requirements, the pitch and diameter of the spiral blade can be flexibly designed. For example, for materials with poor fluidity, a variable pitch design is adopted, with a small pitch at the feed end and a gradually increasing pitch at the discharge end, so that the material is compressed during transportation and the transportation efficiency is improved; if the transportation distance is long, the diameter of the spiral blade can be increased to enhance the transportation capacity.

The fully enclosed trough of the shaftless screw conveyor gives it good sealing performance, which can effectively prevent dust and leakage during material transportation, ensuring the cleanliness and integrity of the material and reducing pollution to the environment. In actual applications, flushing devices, anti-blocking monitoring devices, etc. can also be installed according to needs to further improve the reliability and automation of the equipment, making it widely used in municipal environmental protection, food processing, agriculture and other fields.

Advantages and features of Shaftless Screw Conveyor

The biggest feature of the shaftless screw conveyor is that it abandons the traditional central shaft structure, and the spiral blades are directly welded on the rotating sleeve. This shaftless design gives it a natural advantage in conveying materials that are easy to entangle and have high viscosity. For example, sludge in municipal sewage, fibrous waste generated by food processing, and poultry and livestock manure in the agricultural field will not cause equipment blockage due to winding around the central shaft, which greatly improves the stability and reliability of equipment operation.

In terms of conveying performance, the shaftless screw conveyor performs excellently. It can achieve continuous and stable material conveying, and the conveying process has good sealing. The U-shaped or semi-circular trough body is matched with a sealing cover plate to effectively prevent material overflow and dust flying, which not only ensures the cleanliness of the working environment, but also avoids the contamination of materials during the conveying process. It is suitable for industries such as food and medicine with high hygiene requirements. At the same time, by adjusting the pitch and speed of the spiral blades, the conveying speed and conveying volume of the material can be flexibly controlled to meet the diverse needs of different production scenarios.

From the perspective of maintenance and cost, the shaftless screw conveyor is also quite advantageous. Due to its simple structure and the absence of complex components such as the center shaft, daily inspection and maintenance are more convenient, reducing the difficulty of maintenance and labor costs. When the equipment is running, the friction resistance between the center shaft and the material is reduced, and the energy consumption is relatively low. Long-term use can effectively save the company's operating costs. In addition, its compact structural design makes it occupy a small area and can be flexibly arranged in a small space. Whether it is horizontal transportation or small-angle inclined transportation, it can easily handle it. It is widely used in municipal administration, environmental protection, agriculture, industry and other fields, providing reliable guarantee for the efficient transportation of various materials.

Technical Parameter Table of Shaftless Screw Conveyor

| Model | Screw Diameter (mm) | Capacity (m³/h) | Conveying Length (m) | Motor Power (kW) | Screw Speed (rpm) | Trough Material | Weight (kg) |

|---|---|---|---|---|---|---|---|

| WLS-260 | 260 | 5–10 | 2–12 | 3.0 | 20–40 | Carbon Steel | 800–1500 |

| WLS-320 | 320 | 8–18 | 2–15 | 4.0 | 20–40 | Stainless Steel | 1200–1800 |

| WLS-360 | 360 | 12–25 | 3–20 | 5.5 | 20–40 | Stainless Steel | 1800–2600 |

| WLS-420 | 420 | 18–35 | 3–25 | 7.5 | 20–40 | Stainless Steel + Plastic Liner | 2400–3500 |

| WLS-500 | 500 | 25–50 | 5–30 | 11 | 20–40 | Stainless Steel + Wear Plate | 3000–4500 |

If you have any special requirements, we will customize according to your special needs.

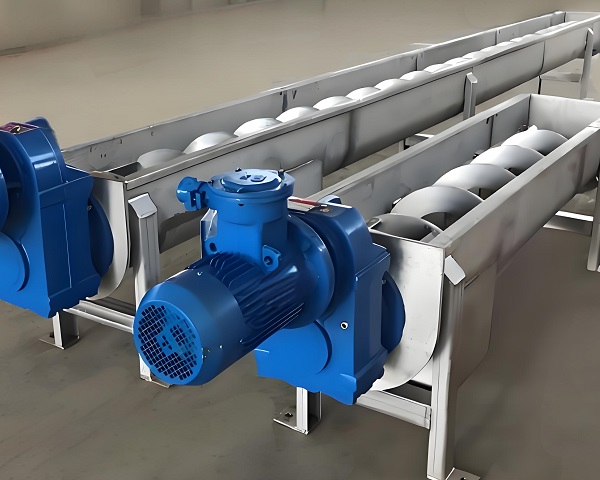

Product Picture Display of Shaftless Screw Conveyor

FAQ about Shaftless Screw Conveyor

>What is the main difference between shaftless screw conveyors and shafted screw conveyors?

Shafted screw conveyors rely on the center shaft to drive the spiral blades to rotate, while shaftless screw conveyors have no center shaft, and the blades are directly fixed on the rotating sleeve. The shaftless design enables it to convey fiber-belted and sticky materials, is not easy to clog, and does not need to remove the center shaft for maintenance, which is more convenient.

>What are the main applications of shaftless screw conveyors?

It is widely used in municipal sewage treatment (transporting sludge, screen residue), food processing (transporting fruit and vegetable waste, meat scraps), agriculture (transporting poultry and livestock manure, straw), papermaking (transporting pulp residue) and other fields, especially suitable for handling materials that are easy to entangle and have strong viscosity.

>What is the conveying capacity of shaftless screw conveyors?

The conveying capacity depends on the diameter of the screw body, the rotation speed and the material characteristics. Generally, the conveying capacity of small equipment is 2-5 cubic meters per hour, and that of large equipment can reach 30-50 cubic meters per hour. The conveying capacity can be flexibly controlled by adjusting the rotation speed.

>Can shaftless screw conveyors convey materials at an angle?

Yes, but the inclination angle should not be too large. It is generally recommended not to exceed 30°. A large inclination angle may affect the conveying efficiency and even cause the material to slide down. In actual use, the inclination angle should be reasonably designed according to the material characteristics and conveying distance.

> How to avoid blockage of shaftless screw conveyor?

Regularly clean the residual materials in the tank to avoid accumulation; control the feed volume to be uniform and stable, and do not exceed the rated conveying capacity of the equipment; for sticky materials, increase the pitch of the spiral blades, add flushing devices, etc. to prevent blockage.

> What does the daily maintenance of shaftless screw conveyor include?

Check the wear of the spiral body and replace the severely worn blades in time; regularly lubricate the bearings and drive devices; clean the adhered materials on the wall of the tank body; monitor the motor current and equipment operation noise, and find abnormalities and troubleshoot in time.

> What is the service life of the shaftless screw conveyor?

Under normal maintenance, the service life of the whole machine is about 5-8 years. As wearing parts, spiral blades and bearings need to be checked and replaced regularly. Reasonable maintenance can extend the overall life of the equipment.

> Can shaftless screw conveyors convey high-temperature materials?

Ordinary material shaftless screw conveyors are not suitable for high-temperature materials. High temperature will accelerate the deformation and wear of the screw body and the trough body. If high-temperature materials need to be transported, high-temperature resistant materials must be used and equipped with cooling devices.

>Is the energy consumption of shaftless screw conveyors high?

Compared with shafted screw conveyors, shaftless screw conveyors have slightly lower energy consumption due to reduced central shaft resistance. Its energy consumption is mainly related to the conveying volume, conveying distance and material characteristics. After optimized design, the unit conveying energy consumption is at the industry average level.

>What are the requirements for the installation of shaftless screw conveyors?

During installation, the equipment must be level or fixed at the designed inclination angle; the trough body connection parts must be tightly sealed to prevent material leakage; the drive device must be firmly installed to avoid vibration during operation; the inlet and outlet must be accurately connected with other equipment.

>Can shaftless screw conveyors be automatically controlled?

Yes, by adding sensors (such as material level sensors, speed sensors) and PLC control systems, automatic start and stop, conveying volume adjustment, fault alarm and other functions can be realized to meet the needs of automated production lines.

>What factors affect the price of shaftless screw conveyors?

The price is mainly affected by factors such as equipment specifications (spiral diameter, length), material (carbon steel, stainless steel), conveying volume requirements, degree of customization and brand. The market price ranges from tens of thousands to hundreds of thousands of yuan.

>Will the shaftless screw conveyor generate dust when conveying materials?

Dust may be generated when conveying powdered materials. Dust spillage can be reduced and the working environment can be improved by sealing the trough, installing a dust collection device or setting a dust cover at the feed inlet.

>Can the shaftless screw conveyor be used in the food industry?

Yes, but stainless steel materials that meet food hygiene standards must be selected to ensure that the surface of the spiral and trough is smooth and has no dead corners, which is easy to clean and disinfect, prevents material residues from breeding bacteria, and meets food safety production requirements.