A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

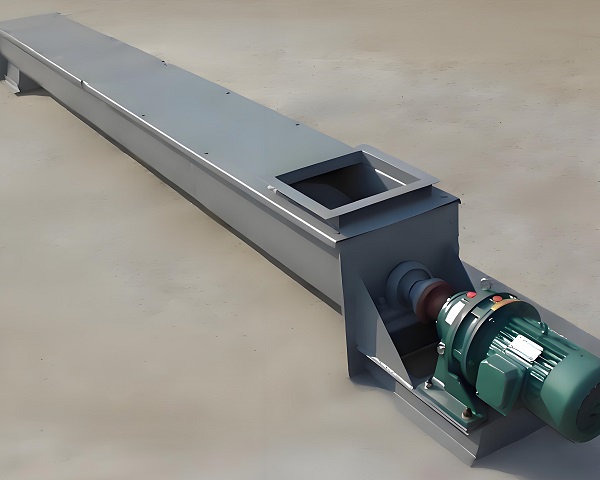

What is the Screw Conveyor

The screw conveyor is mainly composed of spiral blade, drive shaft, chute, driving device and discharge port. The working principle is based on the rotation of the spiral blade. When the motor drives the spiral shaft to rotate, the spiral blade pushes the materials along the chute to realize the conveying of materials from the feed port to the discharge port. Based on different structures, it can be divided into horizontal spiral conveyor, vertical spiral conveyor and inclined spiral conveyor, which can meet various conveying requirements.

The equipment has obvious technical advantages. Compact structure, small floor area, flexible installation in limited space; With good sealing performance and fully enclosed chute design, the material dust can be effectively prevented from flying out, the working environment can be improved, and the material can be protected from moisture and pollution. It is especially suitable for conveying powdery, granular and small materials, such as cement, grains, pulverized coal, etc. In addition, the conveying process of the screw conveyor is stable, and the conveying speed and flow of materials can be conveniently controlled by adjusting the rotating speed of the motor to realize quantitative conveying.

Screw conveyors show strong versatility in their applications. In the grain processing industry, it is used for receiving and cleaning raw grains and conveying finished grains; In chemical production, it can safely transport various powdery chemical raw materials; In the building materials industry, it undertakes the transfer of cement, sand and other materials in the workshop; In the field of environmental protection, it can be used for sludge transportation in sewage treatment plant and material transportation in waste treatment plant; Even in the food industry, the sanitary screw conveyor can be used for conveying food such as chocolate beans and confections to ensure food safety. With the development of technology, screw conveyor is upgrading towards intelligent and energy saving to better meet the increasing material transportation demand of various industries.

Operating principle of Screw Conveyor

The core components of the screw conveyor are helical blades, helical shafts and chutes. Its working principle is based on the helical propulsion mechanism and material movement characteristics. The helical blade is closely welded or sleeved on the helical shaft. When the drive device (such as motor through coupling and reducer) drives the helical shaft to rotate at high speed, the helical blade generates continuous rotational thrust.

In the horizontal conveying process, the materials are subject to the axial thrust generated by the rotation of the spiral blade. Due to the friction between the materials and the inner wall of the chute and the materials, the friction is enough to prevent the materials from rotating with the spiral blade. At this time, the material is like a "nut" pushed by the spiral blade. Driven by the axial thrust, the material moves in a straight line along the inner wall of the chute and moves continuously from the feed inlet to the discharge outlet to realize continuous horizontal conveying.

For vertical or inclined conveying scenarios, the screw conveyor has to overcome the material's own gravity. On one hand, the high-speed rotation of spiral blade gives the upward centrifugal force and spiral thrust to the material; On the other hand, the restriction of the chute prevents the material from spreading around. When the combined force of spiral thrust and centrifugal force is enough to overcome the material gravity and friction with the chute wall, the material can climb up along the spiral blade surface to complete vertical or inclined conveying. In order to guarantee the conveying effect, the vertical screw conveyor usually has higher rotating speed and more compact pitch design.

In addition, the screw conveyor can realize different processing requirements for materials by changing the structure of the helical blades (e.g. variable pitch blade, belt blade) and the configuration (e.g. multi-head screw). Variable pitch blade can compress materials during conveying; Multi-head screw improves conveying efficiency. At the same time, with the help of speed regulating motor or frequency converter, the rotating speed of spiral shaft can be flexibly adjusted, the conveying speed and flow of materials can be accurately controlled, and the demands of diversified production processes can be met.

Advantages and features of Screw Conveyor

The spiral conveyor mainly drives the materials to move along the axial direction of the casing by the rotation of the spiral blade to complete the conveying task. With compact structure and small floor area, it can be flexibly designed into horizontal, inclined and even vertical conveying forms according to the actual needs, and can realize efficient material transmission in a narrow space, especially suitable for workshops, warehouses and other places with limited space.

Screw conveyor has obvious advantages in conveying performance. It can continuously and stably transport powdery, granular and small materials, such as grains, cement, pulverized coal, etc., with good sealing performance during the conveying process. The enclosure is designed to be fully enclosed to effectively prevent dust spillover, reduce environmental pollution, and prevent materials from being affected by damp and scattering, so as to ensure that the quality of materials will not be affected. In addition, by adjusting the rotating speed of the spiral shaft or changing the pitch of the spiral blade, the conveying capacity and conveying speed of materials can be flexibly controlled to meet the diversified demands of different production links.

Screw conveyors are equally outstanding in terms of maintenance and cost. The equipment is composed of a small number of components, mainly composed of spiral shaft, casing and driving device, with simple structure, convenient daily inspection and maintenance, and reduced maintenance difficulty and cost. Moreover, the power consumption is low during operation, and the friction between the spiral blade and the material is small, which can effectively save energy and reduce the enterprise operation cost compared with other conveying equipment. At the same time, the screw conveyor can also realize auxiliary functions such as mixing and mixing in the conveying process. One machine is used for multiple purposes, further improving the utilization rate and cost performance of the equipment. With the development of technology, the screw conveyor has been continuously upgraded in terms of wear resistance, corrosion resistance and other performances, and the applicable scenarios are also continuously expanded, providing reliable guarantee for material transportation in various industries.

Technical Parameter Table of Screw Conveyor

| Model | Capacity (t/h) | Screw Diameter (mm) | Screw Pitch (mm) | Screw Speed (r/min) | Motor Power (kW) | Conveying Length (m) | Inclination (°) | Material |

|---|---|---|---|---|---|---|---|---|

| LS160 | 3–10 | 160 | 160 | 90 | 2.2 | 2–20 | 0–20 | Carbon Steel |

| LS200 | 6–20 | 200 | 200 | 90 | 3.0 | 2–30 | 0–20 | Carbon Steel |

| LS250 | 10–40 | 250 | 250 | 75 | 4.0 | 2–30 | 0–20 | Stainless Steel |

| LS315 | 20–60 | 315 | 315 | 60 | 5.5 | 2–40 | 0–20 | Stainless Steel |

| LS400 | 40–100 | 400 | 400 | 50 | 7.5 | 3–50 | 0–20 | Carbon Steel |

If you have any special requirements, we will customize according to your special needs.

Product Picture Display of Screw Conveyor

FAQ about Screw Conveyor

>What are the types of screw conveyors?

It is mainly divided into horizontal screw conveyor, vertical screw conveyor and inclined screw conveyor. Horizontal type is applicable to short-distance horizontal conveying; Vertical type for vertical lifting; The sloped type is used for transport scenarios with a certain gradient.

>How do I select the appropriate screw conveyor?

Selection is required according to material characteristics (grain size, humidity, viscosity), conveying capacity, conveying distance and installation space. Shaftless screw conveyor can be selected for conveying viscous materials; Larger diameter axial screw conveyors are preferred for high throughput scenarios.

>What is the maximum conveying capacity of the screw conveyor?

The conveying capacity is influenced by the screw diameter, rotating speed, blade form and material characteristics. The hourly conveying capacity of small screw conveyor is about 1-5 tons, and the conveying capacity of large equipment can reach more than 50 tons, and the conveying capacity of special customized model is even higher.

>What are the key points for daily maintenance of screw conveyor?

Regularly check the lubrication of the screw shaft and the bearing, and clean the residual materials in the casing to prevent caking; Tighten the bolts at each connection part to avoid looseness; Monitor the motor current and temperature, and handle abnormal vibration timely.

>What are the common faults of the screw conveyor?

Common failures include broken screw shaft, motor overload, material blockage, etc. The broken screw shaft is mostly caused by conveying overload or hard objects in materials; Overload of the motor may be caused by seized bearing or excessive conveying resistance.

>Does the screw conveyor convey wet material?

Ordinary screw conveyor is easy to cause blocking when conveying wet materials, so shaftless screw conveyor can be selected or additional moisture holes can be added to the shell. However, materials with high water content may still aggravate equipment wear and shorten service life.

>Is the energy consumption of the screw conveyor high?

The energy consumption of screw conveyor is lower than that of belt conveyor and other equipment. The material is directly pushed by the spiral blade, the power transmission efficiency is high, and the energy consumption per unit conveying capacity is about 60% - 80% of the traditional belt conveyor.

>What are the requirements for screw conveyor installation?

The machine body shall be horizontal during installation to avoid material accumulation due to inclination; The shell connection of each section shall be sealed tightly to prevent leakage; The coaxiality of the driving device and the screw shaft shall meet the standard to reduce the operating resistance.

>What is the degree of automation of the screw conveyor?

It can be equipped with frequency converter to realize automatic adjustment of conveying speed. Combined with weighing sensor, material level switch and other devices, it can be linked with PLC control system to meet the accurate feeding requirements of automatic production line.

>What is the service life of the screw conveyor?

Under normal use and maintenance, the service life of the screw conveyor can reach 8-12 years. Vulnerable parts such as spiral blade and bearing shall be replaced regularly. Reasonable maintenance can extend the service life of the whole machine.

>Will the screw conveyor cause damage when conveying materials?

For brittle materials (such as grains and glass particles), high-speed rotating helical blades may cause partial damage. The material damage can be reduced by reducing the rotating speed, adopting variable pitch blade or installing buffer device.