A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

What is the Double-Shaft Waste Tire Shredder

The double-shaft waste tire shredder is a key equipment in the field of waste tire recycling and treatment, and is of great significance to promoting resource recycling and environmental protection.

From the working principle, it relies on two synchronous counter-rotating knife shafts to carry out operations. The knife shaft is equipped with a special blade. When the waste tire enters the shredding chamber, the blade will gradually break the tire into uniform small pieces with strong shear force, tearing force and extrusion force. This crushing method is efficient and stable, and can cope with waste tires of different sizes and thicknesses.

In terms of equipment structure, the double-shaft waste tire shredder is scientifically and reasonably designed. The sturdy and durable frame provides stable support for the entire equipment, ensuring that there will be no shaking or deformation under high-intensity operation. The two knife shafts are connected by a precise transmission system to ensure synchronous speed and smooth operation. The blade is made of high-strength and high-wear-resistant alloy steel. After a special heat treatment process, it has excellent hardness and toughness, can remain sharp for a long time, reduce replacement frequency, and reduce use costs.

The equipment has significant advantages. The crushing efficiency is extremely high, and a large number of waste tires can be processed in a short time, effectively improving production efficiency. The material after crushing has uniform particle size, and the blade spacing can be adjusted according to actual needs to produce rubber fragments of different specifications to meet the diverse subsequent processing requirements. At the same time, the double-axis waste tire shredder has stable and reliable operation, low failure rate, and simple maintenance, which greatly reduces downtime and repair costs.

In terms of application scenarios, it is widely used in tire recycling plants, rubber product companies, and resource recycling bases. Waste tires processed by the shredder can be used as raw materials to produce rubber particles, recycled rubber, waterproof materials, etc., to realize the resource utilization of waste tires, which not only alleviates the environmental pressure caused by the accumulation of waste tires, but also creates considerable economic benefits.

The double-axis waste tire shredder has become an indispensable and important equipment in the waste tire recycling industry with its excellent performance and wide application prospects.

Operating principle of Double-Shaft Waste Tire Shredder

The double-shaft waste tire shredder is a key equipment in the field of waste tire treatment. Its working principle is based on the principle of mechanical mechanics. Through the synergistic effect of two rotating cutter shafts, the waste tires can be efficiently crushed. The following is an analysis from the core structure and operation logic.

Core structure composition

The double-shaft waste tire shredder is mainly composed of two parallel and synchronously counter-rotating cutter shafts, on which many special blades are installed. These blades are arranged according to a certain pattern and spacing to form a strong shearing and tearing action surface. In addition, the equipment is also equipped with a drive system to provide power for the rotation of the cutter shaft; the feed port is used to feed the waste tires into the shredding chamber; and the discharge port is responsible for discharging the crushed materials.

Detailed explanation of operation logic

1.Material entry and initial bite

When the waste tire enters the shredding chamber through the feed port, it will first contact the blades on the two rotating cutter shafts. Since the cutter shafts rotate in the opposite direction, the blades will clamp the tire like a pliers, generating a strong bite force to initially fix the tire in the shredding area.

2.Shearing and tearing action

As the cutter shaft continues to rotate, relative motion will be formed between the blades. This relative movement generates a strong shear force, which cuts the tire like a pair of scissors cutting paper. At the same time, the sharp edge and special shape of the blade will exert a tearing force on the tire, further destroying the structure of the tire. Under the combined effect of shearing and tearing, the tire begins to be gradually broken.

3.Extrusion and crushing completed

During the shearing and tearing process, the knife shaft will also exert an extrusion effect on the tire. After the tire is squeezed, the internal fiber and rubber structure will be further destroyed and become looser. As the knife shaft continues to rotate, the tire is gradually broken into small pieces and finally discharged from the discharge port.

4.Crushing effect guarantee

In order to ensure the crushing effect, the blade material of the double-shaft waste tire shredder is usually made of high-strength and high-wear-resistant alloy steel to ensure that the blade remains sharp during long-term operation. In addition, the equipment is also equipped with an intelligent control system, which can automatically adjust the rotation speed of the knife shaft and the spacing between the blades according to the material, thickness and crushing requirements of the tire to achieve the best crushing effect.

Advantages and features of Double-Shaft Waste Tire Shredder

The double-axis waste tire shredder is a key equipment in the waste tire recycling industry. With its unique design and performance advantages, it plays an important role in the field of resource recycling. Its characteristics and advantages are mainly reflected in the following aspects:

Core features

1. Double-axis collaborative operation: The equipment adopts a double-axis structure, and the two knife shafts rotate synchronously in opposite directions to form a strong shear force and tearing force. This collaborative working mode is similar to two huge "scissors", which can efficiently and stably crush waste tires. Compared with single-axis equipment, the crushing efficiency is significantly improved.

2. Well-designed blades: The blades are made of high-strength, high-wear-resistant alloy steel and are made through a special heat treatment process. They have high hardness and good toughness. The shape and arrangement of the blades have been carefully designed to achieve self-sharpening during the crushing process, and they can remain sharp after long-term use, reducing the frequency of replacement and reducing the cost of use.

3. The feed port has strong adaptability: The feed port is large in size and can accommodate waste tires of different specifications. No pre-cutting is required, and the whole tire can be directly put in. It is easy to operate and saves manpower and time costs.

Significant advantages

1. High crushing efficiency: The strong crushing effect of the double shaft can quickly crush the waste tires into small pieces, with large processing capacity, which can meet the needs of large-scale production. For example, a medium-sized double-shaft waste tire shredder can process several tons of waste tires per hour, greatly improving production efficiency.

2. Uniform crushing particle size: By adjusting the blade spacing and the blade shaft speed, the particle size of the crushed material can be accurately controlled to ensure uniform discharge. Uniform particle size is conducive to subsequent processing, such as the production of rubber particles, recycled rubber, etc., which improves product quality.

4. Stable and reliable operation: The equipment has a sturdy structure and uses high-quality transmission parts and bearings, which runs smoothly, with low noise and low vibration. At the same time, it has an overload protection function. When encountering hard objects or overload conditions, it can automatically shut down to avoid equipment damage and extend the service life of the equipment.

5. Good environmental protection performance: During the crushing process, the equipment is well sealed, which can effectively prevent dust from flying and reduce pollution to the environment. In addition, the crushed waste tires are easy to transport and store, reducing the difficulty and cost of subsequent processing.

Technical Parameter Table of Double-Shaft Waste Tire Shredder

| Item | Unit | TS-800 | TS-1200 | TS-1600 |

|---|---|---|---|---|

| Total Power | kW | 22×2 | 45×2 | 75×2 |

| Main Shaft Speed | rpm | 16–25 | 10–20 | 8–18 |

| Blade Thickness | mm | 20/30 | 30/50 | 50/60 |

| Number of Blades | pcs | 20–30 | 20–40 | 20–50 |

| Shredding Chamber Size | mm | 800×600 | 1200×900 | 1600×1200 |

| Capacity | t/h | 1–3 | 3–6 | 6–10 |

| Output Size (Adjustable) | mm | 30–100 | 30–150 | 50–200 |

| Overall Dimensions (L×W×H) | mm | 2200×1400×1800 | 3200×2000×2200 | 4200×2600×2600 |

| Weight | t | 4.5 | 8.5 | 13.5 |

| Control System | - | PLC Automatic | PLC Automatic | PLC Automatic |

If you have any special requirements, we will customize according to your special needs.

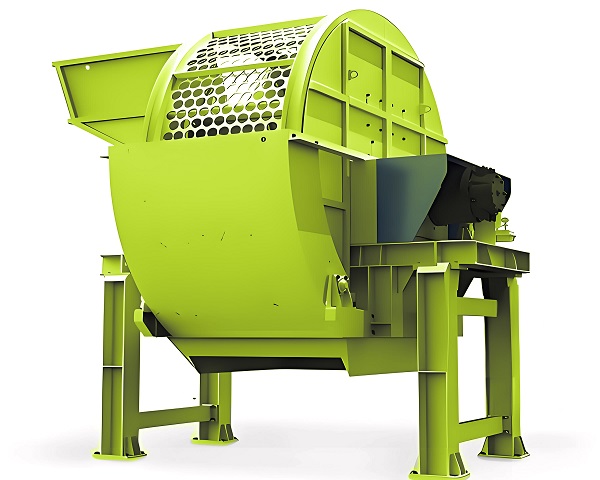

Product Picture Display of Double-Shaft Waste Tire Shredder

FAQ about Double-Shaft Waste Tire Shredder

>1. What is the working principle of the double-shaft waste tire shredder?

The double-shaft waste tire shredder completes the crushing operation through two synchronous counter-rotating knife shafts. The knife shaft is equipped with high-strength alloy steel blades. After the waste tire enters the shredding chamber, the blades shear, tear and squeeze the tire like scissors. The relative movement of the two knife shafts generates a strong force, which gradually breaks the tire into small pieces. At the same time, the blades can be self-sharpened during the crushing process, ensuring long-term and efficient operation, and the crushed materials are finally discharged from the discharge port.

>2. What types of waste tires are suitable for this equipment?

The double-shaft waste tire shredder has a wide range of applications and can handle waste tires of various specifications and materials, including car tires, truck tires, engineering vehicle tires, etc. Whether it is a full steel tire, a semi-steel tire, or a tire with steel wire, it can be effectively crushed. Even waste tires with severe wear and deformation can be smoothly processed by this equipment, providing convenience for subsequent recycling.

>3. Compared with a single-shaft shredder, what are the advantages of a double-shaft shredder?

Double-shaft shredders have the advantages of high crushing efficiency and uniform crushing particle size. The synchronous counter-rotation of the two shafts produces greater shear force and tearing force, faster crushing speed and stronger processing capacity. For example, the amount of tires processed by a double-shaft shredder in the same time may be several times that of a single shaft. Moreover, the double-shaft design makes the crushing process more stable, can better control the particle size of the output material, and meet different subsequent processing requirements, while the single-shaft shredder may be less efficient and uneven when processing harder or thicker tires.

>4. What is the blade material and replacement cycle of the equipment?

The blade of the equipment is usually made of high-strength and high-wear-resistant alloy steel, such as Cr12MoV. After special heat treatment, the hardness of this material can reach HRC58-62, and it has excellent wear resistance and impact resistance. The replacement cycle of the blade depends on factors such as tire material, processing volume and use intensity. Generally speaking, under normal working conditions, the blade can be used continuously for several months or even longer. However, when the blade is worn to a certain extent and affects the crushing effect, it needs to be replaced in time to ensure the normal operation and crushing effect of the equipment.

>5. How to ensure the running stability of the double-axis waste tire shredder?

The equipment adopts a sturdy and durable frame design to provide stable support for the overall operation. High-quality transmission parts and bearings ensure the smooth rotation of the knife shaft and reduce vibration and noise. At the same time, the equipment is equipped with an overload protection device, which can automatically shut down when encountering hard objects or overload conditions to avoid equipment damage. In addition, regular maintenance is also the key to ensuring stable operation, including checking the wear of the blades and lubricating the transmission parts.

>6. What is the performance of the equipment in terms of environmental protection?

The double-axis waste tire shredder performs well in environmental protection. The equipment is well sealed, which can effectively prevent dust from flying during the crushing process and reduce air pollution. The volume of the crushed waste tires is greatly reduced, which is convenient for transportation and storage, and reduces energy consumption and exhaust emissions during transportation. Moreover, the crushed materials can be used to produce rubber particles, recycled rubber, etc., to realize the resource utilization of waste tires and reduce the burden on the environment.

>7. Can the crushing particle size of the double-axis waste tire shredder be adjusted?

It can be adjusted. By adjusting the blade spacing and the blade shaft speed, the particle size of the crushed material can be accurately controlled. For example, if smaller rubber particles are needed, the blade spacing can be appropriately reduced and the blade shaft speed can be increased; if larger pieces are needed, the blade spacing can be increased and the speed can be reduced. This adjustment function enables the equipment to meet the needs of different subsequent processing, such as the production of rubber particles, the production of recycled rubber, and other processes with different requirements for particle size.

>8. What are the key points for equipment maintenance?

The key points for maintenance include: Regularly check the wear of the blades and replace the severely worn blades in time; check the tension of transmission parts such as belts and chains to ensure normal transmission; regularly lubricate the bearings to reduce wear; clean the residual materials inside the equipment to prevent blockage and corrosion; check the electrical system to ensure that the line connection is normal without looseness or short circuit. Regular maintenance can extend the service life of the equipment and ensure its efficient and stable operation.

>9. What factors should be considered when purchasing a double-axis waste tire shredder?

First of all, consider the processing capacity of the equipment and choose a suitable model according to your own production scale. Secondly, pay attention to the material and design of the blades. High-quality blades can improve crushing efficiency and service life. Furthermore, examine the stability and reliability of the equipment, such as the frame structure, transmission system, etc. In addition, after-sales service should also be considered, including installation and commissioning, training, maintenance, etc. Price is also an important factor, but we should not only pursue low prices, but also comprehensively consider the performance and quality of the equipment.

>10. What is the return on investment of the double-axis waste tire shredder?

The return on investment is relatively high. With the tightening of environmental protection policies, the market demand for waste tire recycling has increased. The materials processed by the double-axis waste tire shredder can be used to produce rubber particles, recycled rubber, etc., which have high economic value. The efficient and stable operation of the equipment can reduce processing costs and improve production efficiency. Although the purchase of equipment requires a certain investment, in the long run, its processing capacity, efficient operation and resource recovery value can enable investors to recover costs and make profits in a relatively short period of time, and the return on investment is relatively considerable.