A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

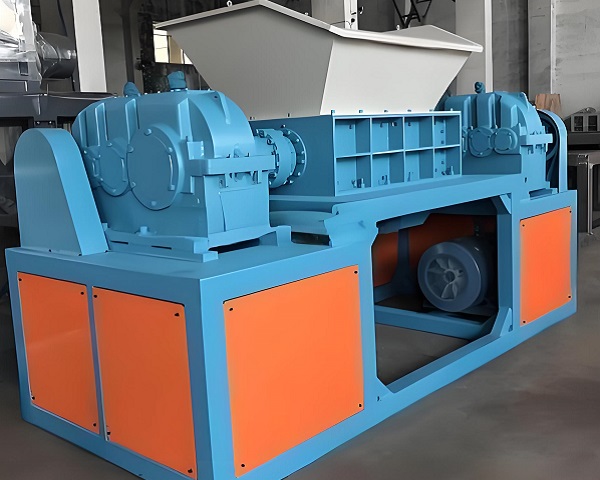

What is the Double-Shaft Industrial Waste Shredder

The double-shaft industrial waste shredder is a device that plays a key role in the field of industrial waste treatment. With its efficient and reliable performance, it helps reduce, recycle and harmlessly treat industrial waste.

From the perspective of structural design, it has two synchronously counter-rotating knife shafts, which are the core components for achieving efficient shredding. The knife shafts are equipped with high-strength and highly wear-resistant blades. These blades are carefully designed and manufactured with sharp edges and sturdy blades that can withstand the strong impact and wear of industrial waste. The knife shaft is connected to the motor through an advanced transmission system to ensure the stability and efficiency of operation. At the same time, the frame of the equipment is made of high-quality steel and has a sturdy structure, which provides reliable support for the entire shredding process.

In terms of working principle, when industrial waste is put into the feed port of the shredder, it will enter the shredding cavity between the two knife shafts. At this time, the motor drives the knife shaft to rotate at high speed, and strong shearing force, tearing force and extrusion force are generated between the blades, just like two crossed and high-speed blades, cutting, tearing and squeezing the waste and breaking it into small pieces. This unique shredding method enables the equipment to handle industrial waste of various types and hardness, such as plastics, rubber, wood, metal scraps, etc.

In terms of application fields, the double-axis industrial waste shredder has a wide range of applicability. In the renewable resource recycling industry, it can shred waste plastics, rubber, etc., which is convenient for subsequent cleaning, smelting and reprocessing to achieve resource recycling; in the field of solid waste treatment, it can pre-treat large pieces of materials in domestic garbage and industrial solid waste, reduce the volume, and improve the efficiency of subsequent sorting, landfill or incineration; in the field of biomass energy, it can shred biomass such as wood and straw to provide suitable raw materials for biomass power generation and biofuel production.

The double-axis industrial waste shredder also has the advantages of stable operation, convenient maintenance, safety and reliability. Its advanced control system can monitor the operating status of the equipment in real time to ensure the safe operation of the equipment. At the same time, the modular design of the equipment makes maintenance and replacement of parts more convenient, reducing the cost of use.

Operating principle of Double-Shaft Industrial Waste Shredder

The double-shaft food waste crusher is a key equipment for processing food waste. Its working principle is based on a unique mechanical structure and mechanical principle. It can efficiently crush food waste into small particles for subsequent processing.

Core structure

The main frame of the equipment is mainly composed of two parallel and synchronously counter-rotating knife shafts. The knife shaft is made of high-strength, wear-resistant alloy steel to ensure that it will not deform or break under long-term high-load operation. There are multiple blades evenly distributed on each knife shaft. The shape and angle of the blades are carefully designed, with sharp edges and solid blades, which can withstand the strong impact and friction of food waste. The knife shaft is installed on a sturdy frame through bearings, and the frame provides stable support for the entire equipment to ensure the stability of the knife shaft during operation.

Detailed explanation of the crushing process

When the food waste is put into the feed port, it enters the crushing chamber between the two knife shafts. At this time, the motor drives the transmission device to make the two knife shafts start to rotate synchronously in the opposite direction. The knife shaft drives the blades to move relative to each other, and strong shearing force, tearing force and extrusion force are formed between the blades.

You can imagine the blades as two crossed and high-speed rotating sharp blades. When food waste passes through, the shear force is like scissors cutting paper, which quickly cuts off the waste; the tearing force is like two hands tearing hard, further decomposing the waste; the squeezing force is like two heavy objects squeezing and crushing the waste. Under the combined action of these three forces, the food waste is quickly cut and shredded into fine particles.

Discharge and particle size control

The crushed food waste particles will be discharged from the discharge port. In order to meet the particle size requirements of different subsequent treatment processes, the pulverizer is equipped with an adjustable blade spacing. By adjusting the blade spacing, the degree of cutting and squeezing of the food waste by the blade can be changed, thereby controlling the size of the crushed particles. For example, when anaerobic fermentation is used to produce biogas, smaller particles are required to improve the fermentation efficiency. At this time, the blade spacing can be appropriately reduced; while in composting, the particle size requirements are relatively loose, and the blade spacing can be appropriately increased.

The double-shaft food waste crusher, with its unique working principle, can efficiently crush food waste into particles of appropriate size, providing a strong guarantee for the resource utilization and harmless treatment of food waste.

Advantages and features of Double-Shaft Industrial Waste Shredder

The Double-Shaft Industrial Waste Shredder plays a key role in the field of industrial waste treatment. Its multiple advantages make it an ideal equipment for treating various types of industrial waste.

1. Efficient and powerful crushing capacity

Dual-axis collaborative operation: The equipment uses two synchronous counter-rotating knife shafts, which are equipped with high-strength and sharp blades. During the crushing process, the two knife shafts cooperate with each other, and strong shearing, tearing and squeezing forces are formed between the blades, like two precise and efficient "scissors". They can quickly cut and tear various industrial wastes, such as plastics, rubber, wood, and metal scraps, into small pieces, and the crushing efficiency is much higher than that of single-axis equipment.

Wide range of processed materials: Whether it is soft plastic film, rubber products, or relatively hard wood and metal scraps, the double-axis industrial waste shredder can easily cope with it. It has a wide range of material adaptability and can meet the treatment needs of waste in different industrial fields.

2. Accurate and controllable discharge particle size

Adjustable blade spacing: The equipment is designed with adjustable blade spacing. The operator can accurately adjust the distance between the blades according to actual needs, thereby controlling the particle size of the crushed material. For example, when the waste needs to be crushed into smaller particles for subsequent recycling, the blade spacing can be appropriately reduced; if only preliminary crushing is required, the blade spacing can be increased. This flexibility enables the equipment to adapt to different subsequent processing processes.

Uniform and stable discharge: Through precise mechanical design and manufacturing process, the double-shaft industrial waste shredder can ensure that the particle size of the crushed material is uniform and stable, avoiding the problem of uneven discharge particle size, which is conducive to improving the efficiency and quality of subsequent processing links.

3. Stable and reliable operating performance

Sturdy and durable structure: The frame and knife shaft are made of high-strength steel to ensure that the equipment will not deform or damage under long-term high-load operation. The blade has undergone special heat treatment, high hardness, good toughness, and strong wear resistance, which greatly extends the service life and reduces the cost of equipment maintenance and blade replacement.

Complete safety protection devices: Equipped with multiple safety protection devices such as overload protection, leakage protection, and emergency stop button. When the equipment encounters abnormal conditions such as overload and leakage, it can automatically stop to avoid equipment damage and safety accidents, and ensure the personal safety of operators.

4. Energy-saving and environmentally friendly design concept

Reduce energy consumption: The equipment adopts advanced transmission system and optimized structural design, which effectively reduces energy consumption while ensuring crushing efficiency, saving operating costs for enterprises.

Reduce pollution: During the crushing process, the equipment adopts a sealed design to effectively prevent dust from flying and reduce pollution to the environment. At the same time, industrial waste is broken into small pieces, which is convenient for subsequent recycling and resource processing, in line with the requirements of sustainable development.

Technical Parameter Table of Double-Shaft Industrial Waste Shredder

| Item | Unit | IS-600 | IS-1000 | IS-1500 |

|---|---|---|---|---|

| Total Power | kW | 18.5×2 | 37×2 | 55×2 |

| Main Shaft Speed | rpm | 15–25 | 10–20 | 8–15 |

| Blade Thickness | mm | 20 | 30 | 40 |

| Number of Blades | pcs | 26 | 34 | 40 |

| Shredding Chamber Size | mm | 600×500 | 1000×800 | 1500×1000 |

| Capacity | t/h | 0.5–2 | 2–5 | 4–8 |

| Output Size (Adjustable) | mm | 30–80 | 30–100 | 50–150 |

| Overall Dimensions (L×W×H) | mm | 1800×1100×1600 | 2800×1800×2100 | 3800×2200×2500 |

| Weight | t | 3.2 | 6.8 | 10.5 |

| Control System | - | PLC Automatic | PLC Automatic | PLC Automatic |

If you have any special requirements, we will customize according to your special needs.

Product Picture Display of Double-Shaft Industrial Waste Shredder

FAQ about Double-Shaft Industrial Waste Shredder

>1. What is the working principle of the double-shaft industrial waste shredder?

The double-shaft industrial waste shredder has two synchronously counter-rotating knife shafts, which are equipped with sharp and sturdy blades. When industrial waste enters the equipment, the motor drives the knife shaft to run at high speed, and strong shearing force, tearing force and extrusion force are generated between the blades. It is like two crossed and rapidly rotating "scissors" to cut, tear and squeeze the waste, breaking it into small pieces, thereby achieving effective treatment of industrial waste of different types and hardness.

>2. What types of industrial waste can it mainly handle?

The equipment can handle many types of industrial waste. In the field of plastics, it can handle plastic bottles, plastic films, plastic barrels, etc.; in terms of rubber, it can handle waste tires, rubber tubes, etc.; wood waste, such as wooden boards, wooden pallets, branches, etc., is also a piece of cake; it can also handle metal scraps, such as iron filings, aluminum filings, stainless steel scraps, etc. In addition, it also has a good handling capacity for some composite materials and waste containing foreign matter.

>3. What are the advantages of a double-shaft industrial waste shredder?

The advantages are significant. First, the crushing efficiency is high. The double-shaft design increases the crushing area and can quickly process a large amount of waste; second, the crushing effect is good, and the waste can be crushed into uniform small pieces for subsequent processing; third, it has a wide range of applications and can process waste of various materials and forms; fourth, it is stable in operation, made of high-quality materials and advanced processes, and has a low failure rate; fifth, it is easy to maintain, and the modular design makes it easier to replace and repair parts.

>4. How to choose a suitable double-shaft industrial waste shredder model?

Choosing a model requires considering many factors. First, it is necessary to clarify the type of waste to be processed, the output and particle size requirements. Different models have different designs for different materials and outputs. Secondly, consider the power and blade speed of the equipment. The power and speed are related to the processing capacity and efficiency. In addition, pay attention to the size and weight of the equipment to ensure that the installation site can accommodate it. Finally, refer to the manufacturer's reputation and after-sales service, and choose products with reliable quality and guaranteed after-sales service.

>5. What are the key points for equipment maintenance?

Maintenance is essential. Check the wear of the blade regularly. If the wear is serious, replace it in time to ensure the crushing effect; check the operation of the knife shaft to ensure that there is no abnormality such as jamming and abnormal noise; clean the residual waste inside the equipment to prevent accumulation from affecting the performance of the equipment; regularly add lubricating oil to the transmission parts to reduce wear; check the electrical system to ensure that the line connection is normal and there are no safety hazards such as leakage.

>6. What are its safety protection devices?

To ensure the safety of operation, the equipment is equipped with a variety of safety protection devices. There is an overload protection device. When the equipment encounters an overload, it can automatically stop to avoid damage to the motor and knife shaft; the leakage protection device can prevent electric shock accidents caused by leakage; the emergency stop button can quickly cut off the power supply and stop the equipment in an emergency; the protective cover covers the dangerous parts such as the knife shaft to prevent the operator from accidental contact and injury.

>7. What is the energy consumption of the double-axis industrial waste shredder?

The energy consumption of the equipment is affected by many factors. Generally speaking, the energy consumption of processing waste of different types and hardness will vary, and the energy consumption of processing waste with high hardness and strong toughness is relatively high. At the same time, the power of the equipment also determines the energy consumption level. The greater the power, the higher the energy consumption. However, the advanced dual-axis industrial waste shredder can effectively reduce energy consumption and improve energy utilization while ensuring the treatment effect by optimizing the transmission system and motor efficiency.

>8. How does it help the subsequent treatment process?

In the subsequent treatment process, the dual-axis industrial waste shredder plays an important role. After the waste is shredded into small pieces, it is easy to sort and improve the sorting efficiency and accuracy; for waste that needs to be recycled and reused, the uniform particles after shredding are more conducive to smelting, pulping and other processing processes; in incineration treatment, small particles of waste burn more fully, improving energy recovery efficiency; in landfill treatment, it can reduce the volume of waste, reduce landfill costs and environmental impact.

>9. How to judge the quality of dual-axis industrial waste shredder?

Quality can be judged from many aspects. Check the material of the equipment. High-quality steel and blade materials can ensure the durability of the equipment. Understand the manufacturing process. Advanced technology can improve the accuracy and stability of the equipment. Inspect the production experience and technical strength of the manufacturer. The product quality of manufacturers with rich experience and strong technology is more guaranteed. Check user reviews and market reputation to understand the performance of the equipment in actual use. You can also conduct field visits and test machines to intuitively feel the performance and quality of the equipment.

>10. What is the development trend of the double-axis industrial waste shredder?

The future development trend is obvious. In terms of intelligence, it will be equipped with more advanced sensors and control systems to realize remote monitoring, automatic adjustment and other functions; in terms of high efficiency and energy saving, it will continuously optimize the design and process to reduce energy consumption; in terms of environmental protection, it will adopt more effective noise reduction and dust reduction measures to reduce the impact on the environment; at the same time, the equipment will develop in the direction of large-scale and automation to meet the growing processing needs and improve production efficiency.