A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

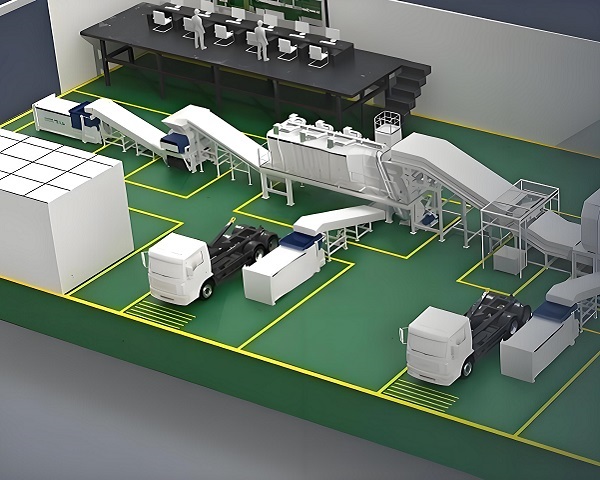

Domestic waste screening project in Russia Introduce

Project Background and Objectives

In medium-sized cities in Russia, with the acceleration of urbanization and the improvement of residents' living standards, the amount of domestic waste generated continues to grow. Traditional waste disposal methods can no longer meet the needs of environmental protection and resource utilization. waste screening is a key link in achieving waste reduction, harmlessness and resource utilization, and is of great significance. This project aims to establish an efficient and reliable domestic waste screening system for medium-sized cities in Russia, improve waste disposal efficiency, increase resource recycling rate, and reduce negative impacts on the environment.

Municipal solid waste screening equipment

Waste composition analysis

Through the investigation and analysis of the composition of domestic waste in medium-sized cities in Russia, its main components include: paper (about 30%-40%), commonly newspapers, magazines, office paper, wrapping paper, etc.; plastic (about 20%-30%), covering plastic bottles, plastic bags, plastic tableware, plastic packaging, etc.; metal (about 5%-10%), mainly cans, tin cans, scrap metal products, etc.; organic matter (about 20%-30%), such as food residues, fruit peels, vegetable leaves, etc.; others (about 10%-20%), including glass, ceramics, masonry, ash, etc. Understanding these components is crucial for the rational selection of screening equipment and the design of process flow.

Municipal solid waste screening equipment

Equipment selection

1. Plate conveyor

Use a general series of large and medium-sized plate conveyors, which are suitable for conveying waste along horizontal or inclined working sections. It has the characteristics of large traction, strong carrying capacity, low energy consumption, corrosion resistance, impact resistance, continuous unloading, etc., and can adapt to harsh working conditions such as complex materials and open air. The transmission system adopts a planetary cycloid pinwheel reducer, which has a large transmission ratio, high efficiency, small size, few faults, long life, reliable and stable operation, low noise, easy maintenance, strong overload capacity, impact resistance, small inertia moment, and is suitable for frequent start-up scenarios. The equipment trough junction has good airtightness, which effectively prevents material leakage. The unique trough shape and small gap can prevent waste from being stuck or blocked during dumping or transportation. The conveyor belt is welded from high-quality bent steel plates and structural steel, with good rigidity. The arcs on both sides of the bent steel plate play a role in sealing and stabilizing in different curvatures, which can well suppress the complexity and instability of waste. For example, in a waste treatment project, the plate conveyor operates stably and transports a large amount of waste every day, ensuring the smooth progress of the subsequent treatment process.

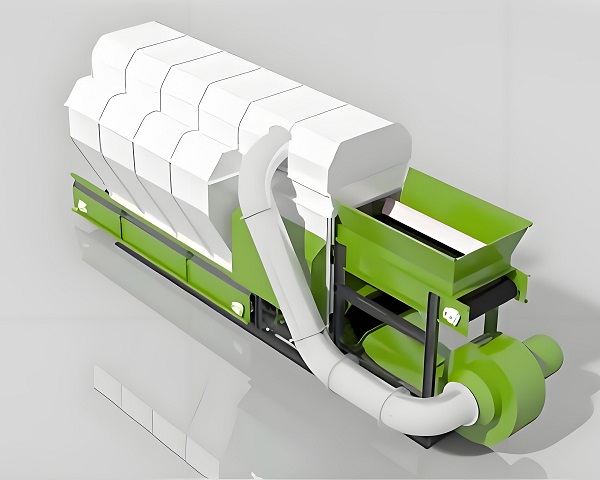

2. Fabricator

The fabricator is a fabricator that is independently developed using advanced foreign technology and is suitable for the composition of local waste materials. The use of a trapezoidal symmetrical arc spiral scraper can effectively alleviate the phenomenon of waste entanglement with the drum, waste accumulation, and bridging, with a material distribution rate of up to 70%-95%. It should be noted that it is strictly forbidden to feed large objects (such as tree trunks and branches, large pieces of cloth, thin and long cloth strips, iron wires, and other large objects larger than 200mm, as well as stones, construction waste, etc.) into the material distribution machine. In actual application, this material distribution machine can evenly distribute waste to subsequent equipment, improving the screening efficiency and effect.

3. Large-piece sorting belt conveyor

The belt conveyor is suitable for short-distance transportation of bulk materials in waste treatment. It has the characteristics of large conveying capacity, long single machine length, low energy consumption, simple structure, and easy maintenance. It is mainly composed of six parts: conveyor belt, drive device, roller, roller, electrical protection device, and safety protection device. Sensors are used to protect equipment, and safety protection devices (such as pull-wire switches) are used to ensure personnel safety. In the large-item sorting process, the belt conveyor runs at a suitable speed, which makes it convenient for the sorting personnel to pick out the large items on the belt (such as wood, bamboo, cardboard, and large fabrics). At the same time, the oversized plastic bags are manually broken open to expose the bottles and other items inside, thereby improving the subsequent screening efficiency.

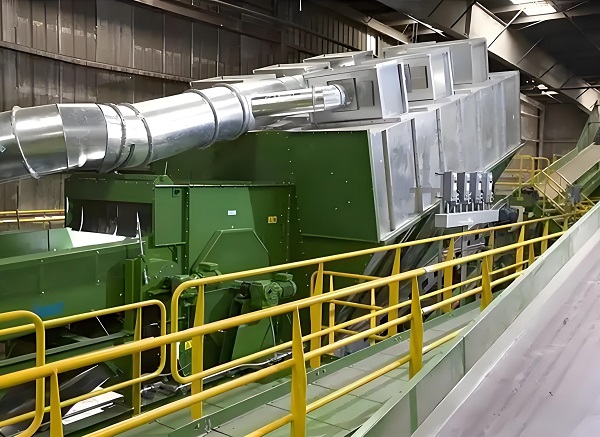

Domestic waste screening trommel screen

4. Trommel screen

The trommel screen is a rotating body with a screen attached, which is driven and supported by 4 load-bearing rollers. The guide plate and bag-breaking cutter teeth are installed inside the rotating body. It can receive the feed from the belt conveyor in the previous link. Under the rotation of the trommel screen, the mixed waste is screened according to the particle size, such as dividing the waste into two parts with a particle size greater than 100mm (or set according to actual needs, such as 60mm) and less than the particle size. The screened oversize and undersize are discharged from the trommel screen respectively to complete the screening task. For example, in a waste screening project in a certain city, the trommel screen effectively separates the fine particles and larger lumps in the mixed waste, providing convenience for subsequent targeted treatment.

5. Bottle separator

It is used to separate bottle materials from waste. On the bottle separation belt conveyor, bottle items will roll down to the material box in the opposite direction of the belt, and the remaining materials will be sent to the manual sorting belt conveyor along the forward direction of the belt. In actual operation, this equipment can efficiently separate plastic bottles, glass bottles, etc. from mixed waste, improving the recycling efficiency of bottle resources.

6. Manual sorting platform

The manual sorting platform is equipped with multiple workstations (such as 8 workstations), and the manual sorting belt conveyor slowly (such as 0.3 m/s) delivers materials to each workstation. There is a lower hopper on the right side of each workstation, and different collection devices are connected to the lower part of the lower hopper. Among them, paper and plastic are connected to the belt conveyor, and the rest of the materials are connected to the mobile material box. Through manual sorting, different types of materials such as plastics, paper, remaining glass bottles, cans, etc. can be selected. If you need to increase the types of sorted materials, you can add more human selection stations. The manual sorting platform is surrounded by guardrails and ladders for people to go up and down to ensure the safety of operators. In actual operation, manual sorting can flexibly identify and select various materials with recycling value, making up for the shortcomings of mechanical screening.

Domestic waste screening trommel screen

7. Magnetic separator

The RCYD series electromagnetic self-unloading iron remover is composed of high-performance electromagnetic core, discarded iron belt, reduction motor, frame, drum and other parts, which are used to automatically remove 0.1-25kg magnetic materials from non-magnetic materials. Its internal magnetic circuit adopts computer simulation design and perfect double-pole structure to ensure the long-term operation of the whole machine without trouble in harsh environment. For example, in a waste treatment plant, the magnetic separator can effectively separate magnetic materials such as metal cans and iron sheets from waste, realize the recycling of metal resources, and avoid the damage of metal to subsequent processing equipment.

8. Mobile material box

It is used to collect and transport different types of waste materials. It has the characteristics of convenient movement and loading and unloading, and the quantity and specifications can be flexibly configured according to actual needs. In the waste screening project, the mobile material box collects and transports the materials sorted out in each link to the designated location in time, ensuring the smooth progress of the entire screening process.

Project Benefit Analysis

Municipal waste screening equipment

1. Environmental Benefits

Through the effective screening of domestic waste, recyclables can be recycled, reducing resource waste and the exploitation of primary resources, and reducing the ecological damage caused by resource exploitation. For example, recycled paper can reduce tree felling, and recycled metals can reduce the smelting of metal ores, thereby protecting the ecological environment.

The amount of landfill is reduced, and the occupation of land resources and the risk of soil and groundwater pollution by landfill are reduced. At the same time, the amount of waste incineration is reduced, the emission of harmful gases (such as dioxins, etc.) during the incineration process is reduced, and the air quality is improved.

Separate treatment of organic matter (such as composting, etc.) can realize the resource utilization of organic matter, reduce the greenhouse gas emissions generated by the decomposition of organic matter in the natural environment, and help to cope with climate change.

2. Economic Benefits

Recycled recyclables (such as paper, plastic, metal, etc.) can be sold to related companies to obtain certain economic benefits. With the development of the resource recycling market and the improvement of recycling technology, the value of recyclables will gradually increase, bringing more economic benefits to the project.

Through waste screening and reasonable treatment, the cost of waste disposal is reduced. Compared with traditional waste disposal methods, such as direct landfill or incineration, the comprehensive treatment cost of this project is lower, which improves the economic benefits of waste disposal.

The implementation of the project has driven the development of related industries, such as equipment manufacturing, transportation, resource recycling and utilization, created employment opportunities, and promoted the development of the local economy.

Municipal waste screening equipment

3. Social benefits

It has improved the city's environmental sanitation level, improved the living environment of residents, and improved the quality of life and happiness of residents.

It has enhanced the environmental awareness of residents. Through the publicity and implementation of the project, residents have a better understanding of the importance of waste classification and resource recycling, and promoted the formation of environmental protection behaviors of residents.

It has provided strong support for the sustainable development of the city, promoted the practice of the concept of green development in the city, and enhanced the image and competitiveness of the city.

This Russian medium-sized city domestic waste screening project plan can effectively screen and classify domestic waste through the reasonable selection of plate conveyors, material distribution machines, trommel screens and other equipment, and the design of scientific process flow, so as to achieve waste reduction, harmlessness and resource treatment. After the implementation of the project, it will bring significant environmental benefits, economic benefits and social benefits, and make positive contributions to the sustainable development of medium-sized cities in Russia. During the project implementation process, it is necessary to strictly follow the project implementation plan, strengthen equipment installation and commissioning, personnel training and project operation management, and ensure the smooth progress of the project and long-term stable operation.

Advantages and features of Domestic waste screening project in Russia

Features and advantages of the project plan for domestic waste screening in medium-sized cities in Russia:

1. Strong adaptability of equipment and outstanding processing capacity

The equipment selected in the plan fully considers the characteristics of complex composition and harsh working conditions of domestic waste in medium-sized cities in Russia. The plate conveyor adopts a planetary cycloid pinwheel reducer with high transmission efficiency and impact resistance. The unique material trough and conveyor belt design can effectively suppress the complexity and instability of garbage and ensure efficient transportation of garbage; the material distributor uses advanced foreign technology and uses a trapezoidal symmetrical arc spiral scraper to increase the material distribution rate to 70%-95%, solving the problem of garbage entanglement and accumulation, and laying the foundation for subsequent screening. These equipment combinations form a powerful processing capacity, which can realize efficient sorting and screening of various types of domestic waste.

2. Scientific process flow and efficient resource recovery

The project process flow is scientifically and reasonably designed, covering multiple links such as garbage entry weighing, unloading, transportation, sorting, screening, etc., and each link is closely connected. First, large pieces of garbage that affect subsequent processing are removed through large-piece sorting, and then the drum screen is used for particle size screening. In combination with the bottle separator, manual sorting platform and magnetic separator, the paper, plastic, metal, bottle and other recyclables can be accurately separated. This refined process design maximizes the resource recycling rate, fully recycles all kinds of resources in the garbage, and reduces resource waste.

3. Intelligent electrical control, safe and stable operation

Adopting PLC centralized control mode, with automatic and manual selection modes, which can be flexibly switched according to actual needs. At the same time, it has functions such as overvoltage and overcurrent self-protection, fault alarm, equipment status display, etc., and is equipped with an emergency stop button and electric shock protection device, which can not only ensure that the equipment automatically cuts off the power supply and promptly alarms for maintenance under abnormal conditions, but also ensure the personal safety of operators, and realize the intelligent, safe and stable operation of the equipment.

4. The project has significant benefits and high comprehensive value.

In terms of environmental benefits, it reduces the amount of landfill and incineration, reduces pollution risks, protects soil, groundwater and air quality, and promotes the resource utilization of organic matter; in terms of economic benefits, it obtains income through recycling recyclables, reduces waste disposal costs, and drives the development of related industries; in terms of social benefits, it improves the level of urban environmental sanitation, enhances residents' environmental awareness, provides support for urban sustainable development, and enhances the city's image and competitiveness. The comprehensive benefits of the project reflect its important value in environmental protection, economy and society.

5. The implementation plan is perfect to ensure the implementation of the project.

From project preparation, equipment procurement and transportation, to installation and commissioning, personnel training, trial operation and formal operation, detailed implementation plans and time nodes have been formulated. Clarifying the tasks and goals of each stage to ensure the orderly advancement of the project provides a strong guarantee for the smooth implementation and long-term stable operation of the project.

Main Machine

Customer Feedback

As the implementer of the domestic waste screening project, we are very satisfied with this plan and the implementation effect of the project. The adaptability of the equipment in the plan is amazing. The plate conveyor and the placing machine show excellent performance when dealing with complex garbage components, ensuring the efficient operation of garbage treatment, and there has never been a processing stagnation due to equipment problems.

The scientific process is a highlight of the project. From large-scale sorting to precise separation of various resources, every link is closely coordinated, and the resource recycling rate is far beyond expectations, providing a strong boost for the recycling of urban resources. The intelligent design of electrical control not only makes the equipment run stably, but also greatly reduces the operating risks and ensures the safety of staff.

The comprehensive benefits brought by the project are significant, the environment has been significantly improved, and residents' satisfaction with urban sanitation has been greatly improved; the economic benefits created by resource recycling have also injected new vitality into urban development. The perfect implementation plan allows the project to be successfully implemented, and each stage can be advanced as expected. This plan truly achieves a win-win situation for environmental protection and economy. It is an excellent example in the field of urban waste treatment and is worth promoting to more cities!