A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

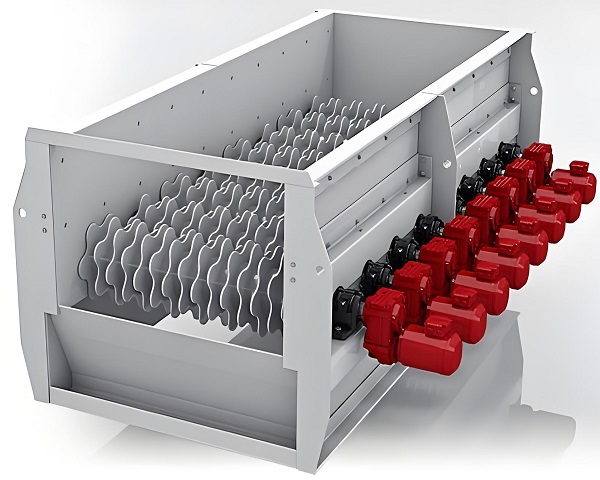

What is the Star Screen

Star screen is a highly efficient screening equipment, named for its unique structure of star-shaped screen discs. With its innovative design and excellent performance, it plays an important role in solid waste treatment, resource recycling, building materials processing and other fields.

The core working principle of the star screen is based on a rotating star-shaped screen disc group. These screen discs are composed of multiple radially distributed steel fingers, similar to the shape of stars, and are driven by a motor to rotate. When the material enters the screening area, under the combined action of the centrifugal force and gravity generated by the rotation of the screen disc, the material smaller than the gap of the screen disc is separated and falls, and the material larger than the gap continues to move forward under the push of the screen disc until it is discharged from the screen body, thereby achieving accurate classification of materials of different particle sizes.

In terms of structural design, the star screen has unique advantages. Its modular design makes it easy to disassemble and replace key components such as the screen disc and the drive system, which not only reduces the difficulty of maintenance, but also can quickly adjust the screen disc spacing and speed according to the characteristics of different materials, greatly improving the adaptability of the equipment. In addition, the equipment has less vibration and runs smoothly during operation, which effectively reduces the impact on the surrounding environment and prolongs its service life.

The application scenarios of the star screen are very wide. In the field of domestic waste treatment, it can effectively separate different types of waste such as kitchen waste, plastic, paper, etc., to help the subsequent resource utilization and harmless treatment; in the recycling of construction waste, it can screen concrete blocks, bricks, sand and gravel, etc., and convert them into recycled aggregates for re-production; in the biomass energy industry, it can also easily screen biomass raw materials such as wood chips and straw, providing high-quality raw materials for biomass power generation and biofuel production.

Compared with traditional screening equipment, the star screen has significant advantages. It can handle complex materials that are wet, sticky, and easy to entangle, and is not prone to clogging problems, and the screening efficiency is greatly improved; the energy consumption is relatively low, and while achieving efficient screening, it reduces operating costs. However, the star screen also has certain limitations, such as the relatively limited screening accuracy for ultra-small particle size materials, and the high initial investment cost of the equipment.

With the increasingly stringent environmental protection requirements and the growing demand for resource recycling, the star screen has a very broad market prospect with its own technical advantages. In the future, by combining with intelligent control systems, the star screen is expected to achieve more precise parameter adjustment and automated operation, further enhancing its competitiveness in the field of material screening.

Operating principle of Star Screen

The working principle of the star screen relies on its unique structural design and mechanical mechanism, and realizes efficient screening of materials through the synergy of rotational motion and force.

The core component of the star screen is the star-shaped screen disc group. Each screen disc is composed of multiple radially distributed steel fingers, shaped like a star. These screen discs are connected in series through the central axis and driven by a motor to rotate at high speed. When the material enters the screening area, it will be affected by multiple forces. The first is the centrifugal force generated by the rotation of the screen disc, which makes the material quickly diffuse to the edge of the screen disc, increases the contact area between the material and the screen disc, and creates conditions for screening; at the same time, the gravity of the material itself also plays a role in the screening process, and the two cooperate with each other to promote the movement of the material.

Materials smaller than the gap between the steel fingers of the screen disc can smoothly pass through the gap under the combined force of centrifugal force and gravity, fall from the bottom of the screen disc, and complete the initial screening. Materials larger than the gap, because they cannot pass through the screen disc, will move forward along the surface of the screen disc under the continuous push of the steel fingers of the screen disc. In this process, the material and the screen disc constantly collide and roll, further ensuring the full separation of materials of different particle sizes. Finally, the larger materials will be pushed to the end of the screen body for discharge, thus achieving accurate classification of materials of different particle sizes.

The star disc screen can also optimize the screening effect by adjusting the screen disc spacing and rotation speed. The screen disc spacing directly determines the upper limit of the material particle size that can pass through the screen disc. Users can flexibly adjust the spacing according to actual needs to adapt to the screening requirements of different materials. The rotation speed affects the size of the centrifugal force on the material. The higher the speed, the greater the centrifugal force, the faster the material moves on the screen disc, and the higher the screening efficiency. However, too high a speed may cause the material to be discharged without being fully screened. Therefore, the operator needs to reasonably set the screen disc spacing and rotation speed according to the material characteristics to achieve the best screening accuracy and efficiency.

It is precisely with this unique working principle that the star disc screen can efficiently handle various complex materials and show strong performance advantages in the fields of solid waste treatment and resource recycling.

Advantages and features of Star Screen

Star screen stands out in the field of material screening with its unique design and excellent performance. Its characteristics and advantages are remarkable, bringing efficient solutions to multiple industries.

In terms of structural design, the star screen is very distinctive. It adopts a modular design, and key components such as the screen plate and drive system are easy to disassemble and replace. This feature not only greatly reduces the difficulty and time cost of equipment maintenance, but also can quickly adjust the screen plate spacing and speed according to different material characteristics to achieve flexible adaptation. Its star-shaped screen plate is composed of radially distributed steel fingers. This special structure makes the material evenly stressed during the screening process, runs smoothly, and the equipment vibrates less, reducing the impact on the surrounding environment and extending its service life.

In terms of working performance, the star screen has outstanding advantages. It can efficiently handle complex materials that are wet, sticky, and easy to entangle, which is difficult for traditional screening equipment to achieve. The centrifugal force generated by the rotation of the screen plate cooperates with gravity to fully disperse the material on the screen plate, effectively avoiding the problem of material blocking the screen holes, and greatly improving the screening efficiency. In addition, the star screen has relatively low energy consumption. While ensuring efficient screening, it reduces the operating costs of the enterprise and achieves a win-win situation of economic and environmental benefits.

From the perspective of application scenarios, the star screen has strong adaptability and a wide range of applications. In the treatment of domestic waste, it can accurately separate different types of waste such as kitchen waste, plastics, and paper, which helps the subsequent resource utilization and harmless treatment; in the field of construction waste recycling, it can screen concrete blocks, bricks, sand and gravel into recycled aggregates to promote resource recycling; in the biomass energy industry, it also performs well in screening biomass raw materials such as wood chips and straw, providing high-quality raw materials for biomass power generation and biofuel production.

Although the star screen has limited screening accuracy for ultra-small particle materials and high initial investment costs, its unique structural design, excellent working performance and wide application adaptability make it an indispensable and important equipment for modern material screening. With the continuous development and improvement of technology, the star screen is expected to play a greater role in more fields and continue to inject new impetus into the development of the industry.

Technical Parameter Table of Star Screen

| Model | No. of Star Shafts | Shaft Length (mm) | Screen Aperture (mm) | Capacity (TPH) | Motor Power (kW) | Screening Efficiency (%) | Dimensions (mm) |

|---|---|---|---|---|---|---|---|

| SS-600 | 6 | 1000 | 20 – 40 | 15 | 3.0 | 85 | 2500×1200×1300 |

| SS-900 | 8 | 1200 | 30 – 50 | 25 | 4.0 | 88 | 3000×1400×1400 |

| SS-1200 | 10 | 1500 | 40 – 60 | 40 | 5.5 | 90 | 3500×1500×1500 |

| SS-1600 | 12 | 1800 | 50 – 70 | 60 | 7.5 | 92 | 4000×1600×1600 |

| SS-2000 | 14 | 2000 | 60 – 80 | 90 | 11.0 | 94 | 4500×1800×1700 |

| SS-2500 | 16 | 2200 | 70 – 100 | 120 | 15.0 | 96 | 5000×2000×1800 |

If you have any special requirements, we will customize according to your special needs.

Product Picture Display of Star Screen

FAQ about Star Screen

>In which industries is Star Screen mainly used?

In municipal solid waste treatment, it is used to separate organic and inorganic materials to facilitate recycling and composting; in the field of construction and demolition waste treatment, it can screen wood, metal, aggregates, etc. for recycling and reuse; in the biomass processing industry, it screens biomass such as wood chips and green waste for energy production and composting; in recycling plants, it can separate recyclables such as plastics, paper, and metals by size; during composting operations, it removes impurities and separates high-quality organic materials to produce high-quality compost.

>What are the advantages of Star Screen compared to other screening equipment?

Compared with traditional screening equipment, it has better screening effects on wet, sticky, and easily entangled materials because its unique star disk design can reduce material blockage. It has high screening efficiency and can continuously and efficiently process large amounts of materials. The equipment operates stably, has low vibration, and has relatively low requirements for the installation foundation. The modular design makes maintenance and replacement of parts more convenient and reduces maintenance costs.

>What is the processing capacity of Star Screen?

The processing capacity depends on equipment specifications, material characteristics, etc. Common models have an hourly processing capacity ranging from tens to hundreds of cubic meters, and large equipment can reach 900 cubic meters per hour. The material has good fluidity and uniform particles, and the processing capacity is relatively high; the material has high viscosity and complex composition, and the processing capacity will be affected.

>Can Star Screen handle wet materials?

Yes. The rotation of the star disc makes the material constantly jump and roll, reducing the adhesion and accumulation of wet materials on the screen surface, and effectively preventing the sieve holes from being blocked. Even when handling materials with high moisture content, such as wet garbage and wet biomass raw materials, it can maintain good screening performance.

>How to choose a suitable Star Screen model?

Material characteristics (particle size, shape, humidity, viscosity, etc.), processing capacity requirements, screening accuracy, and budget need to be considered. For processing large-particle materials, choose equipment with large-size star discs and large gaps; for high screening accuracy requirements, choose models with small star disc gaps and close arrangement; for large processing capacity, large-size equipment is suitable; at the same time, balance equipment performance and cost based on budget.

>Is Star Screen complex to install?

Due to its modular design, installation is relatively simple. First, transport each module of the equipment to the installation site, assemble according to the instructions, connect the rotating shaft, star disk and other components, install the motor and transmission device, and ensure that all components are firmly connected. During debugging, check the horizontality of the equipment, the flexibility of the rotating parts, run the equipment without load, observe the operating status of the equipment, and perform load debugging after no abnormality.

>What aspects does Star Screen daily maintenance include?

It is necessary to regularly clean the residual materials on the surface and gap of the star disk to prevent material accumulation from affecting the screening effect; check the lubrication of the rotating shaft, motor and other components, and replenish lubricating oil in time; check whether the various connection parts of the equipment are loose, and tighten them in time if they are loose; monitor the vibration and noise of the equipment during operation, and troubleshoot the faults in time if abnormalities are found.

>What faults may occur during the operation of Star Screen?

Common faults include material blockage, which may be caused by high material viscosity, too small star plate gap or uneven feeding. It is necessary to adjust the feeding, clean the screen surface or replace the appropriate equipment; motor failure, such as overheating and non-operation, may be caused by overload, insufficient lubrication, etc., and the motor and circuit need to be checked, and the damaged parts need to be repaired or replaced; abnormal equipment vibration may be caused by component wear and loose installation. Check the wear and tighten the components again.

>Can Star Screen be customized?

Yes. Manufacturers can customize according to customer's special needs, such as designing special star plate structure for special shape materials; increasing equipment size and motor power for high processing capacity requirements; and customizing compact or special layout equipment according to site space limitations.

>Does Star Screen have high energy consumption?

Through optimized design and selection of high-efficiency motors, the energy consumption is at a reasonable level. Compared with some screening equipment of the same type, its energy consumption is not high. The energy consumption of equipment operation is related to the processing capacity, material characteristics, and equipment speed. Reasonable adjustment of operating parameters can reduce energy consumption and reduce operating costs.

>How long is the service life of Star Screen?

Under normal use and maintenance, key components such as star disks and rotating shafts are made of high-quality wear-resistant materials and can last for several years. However, due to the degree of material wear, frequency of use, and quality of maintenance, the service life may be shortened when processing high-hardness and highly corrosive materials. Regular maintenance can extend the overall service life of the equipment.

>How effective is Star Screen in screening recyclables of different materials in the recycling industry?

It performs well in the recycling industry. For plastic recyclables, it can screen different types of plastics by size, which is convenient for subsequent classification and processing; when processing paper recyclables, it can separate different specifications of paper and remove impurities; for metal recyclables, it can screen metal parts of different sizes to improve the purity and efficiency of recycling and help effectively recycle resources.

>What are the safety precautions when operating Star Screen?

When operating, wear protective gloves, goggles and other protective equipment to prevent material splashing and injuring people; it is strictly forbidden to open the protective device when the equipment is running to avoid contact with rotating parts; regularly check the grounding of the equipment to ensure electrical safety; before cleaning or repairing the equipment, be sure to cut off the power supply and wait until the equipment stops rotating completely before operating to prevent accidental startup and danger.