A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

What is the Roller Screen

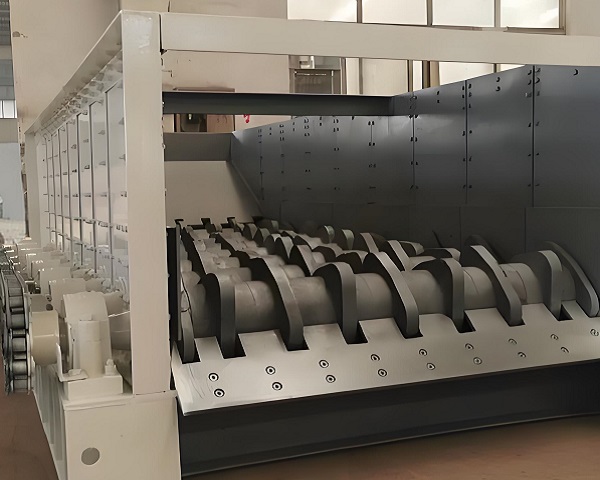

The roller screen is a mechanical device that relies on multiple parallel arranged and specially structured screen shafts to rotate to achieve material screening. It is widely used in many industries such as electricity, mining, metallurgy, and building materials. Its core working principle is to drive the reducer through the motor to drive the screen shaft to rotate. After the material enters the screen surface, under the rotation and material-shifting action of the screen shaft, the material smaller than the gap of the screen shaft falls to complete the screening, and the material larger than the gap moves forward along the screen shaft to the discharge port for discharge.

The structural design of the roller screen is exquisite and practical. It consists of multiple screen shafts arranged in parallel to form a screen surface. The screen shaft is equipped with screen pieces of special shapes, such as banana shape and trapezoidal shape. These screen pieces not only have strong wear resistance, but also can effectively prevent material jams. The screen shaft spacing can be flexibly adjusted according to the particle size of the material and the screening requirements. Usually, a segmented design is adopted. The front section screen shaft spacing is large, which is used to quickly separate small particle materials, and the spacing of the rear section gradually decreases to achieve fine screening. In addition, the sealing device equipped with the equipment can effectively prevent dust from spilling out and ensure a clean and safe working environment.

In terms of performance, the roller screen has significant advantages. First, the screening efficiency is high. The rotation of the screen shaft makes the material move forward in a spiral shape on the screen surface, fully contacting the screen surface, reducing the accumulation and blockage of the material, and the processing volume per unit time far exceeds that of the traditional vibrating screen. Second, it has strong adaptability. Whether it is ore with uneven particle size, wet coal, or sticky domestic garbage, effective screening can be achieved by adjusting the parameters such as the screen shaft speed and the screen structure. Third, the operation is stable and reliable. The roller screen adopts low-speed operation, the equipment has small vibration, low noise, small wear of mechanical parts, and long maintenance cycle, which reduces the operating cost of the enterprise.

In actual application scenarios, the roller screen is very useful. In thermal power plants, it is used to screen the coal entering the furnace, and send coal of qualified particle size into the boiler to improve combustion efficiency; in the mining industry, it can perform preliminary screening on the mined ore, separate the waste rock, and improve the ore grade; in the field of urban waste treatment, it can effectively separate recyclable materials such as plastic, paper, and metal from the garbage, creating conditions for subsequent resource utilization. With the continuous advancement of technology, roller screens are developing towards intelligence and large-scale, providing stronger support for efficient production in various industries.

Operating principle of Roller Screen

The roller screen is an efficient screening equipment, which is mainly composed of multiple parallel rollers, drive devices, frames and other components. Its working principle is based on mechanical movement and material size differences, and precise screening is achieved through ingenious structural design.

When the equipment is running, the drive device drives multiple rollers to rotate synchronously. The roller surface is usually provided with screens or screen plates of special shapes. These screens or screen plates are arranged according to a certain pattern to form a screen hole gap. After the material to be screened enters the roller screen from the feed inlet, it first contacts the rotating roller. Due to the thrust generated by the continuous rotation of the roller, the material moves on the screen surface along the arrangement direction of the roller. During the movement, the material particles smaller than the size of the screen hole fall through the gap of the screen hole under the action of gravity and the mechanical force generated by the rotation of the roller, becoming the undersize; while the material particles larger than the size of the screen hole continue to move on the surface of the roller until they are discharged from the discharge port and become the oversize, thus completing the screening process.

In order to improve the screening effect, the roller screen has many ingenious designs. On the one hand, the speed and direction of the roller can be adjusted according to the characteristics of the material. For materials with good fluidity and obvious differences in particle size, appropriately increasing the roller speed can speed up the screening speed; for materials with high viscosity and easy to agglomerate, the speed can be reduced and the roller steering can be adjusted. The rubbing and squeezing between the rollers can be used to disperse the materials, avoid clogging the sieve holes, and ensure smooth screening. On the other hand, the sieve holes of the roller screen are of various shapes and sizes, and the common ones are round, square, and strip. Users can choose the appropriate sieve hole specifications according to actual needs. For example, the circular sieve hole has a higher screening accuracy and is suitable for materials with strict particle size requirements; the strip sieve hole is more suitable for processing sheet and strip materials to prevent the material from getting stuck in the sieve hole.

Some roller screens are also equipped with cleaning devices, such as brushes and scrapers. These devices can promptly remove materials attached to the rollers and sieve holes, further ensure the smooth flow of the sieve holes, and maintain the long-term stable operation of the equipment. With its unique working principle and structural design, the roller screen has been widely used in many industries such as coal, ore, garbage disposal, and building materials, and has become an important equipment in the material screening process.

Advantages and features of Roller Screen

In terms of screening efficiency, the roller screen performs excellently. It drives the material forward and achieves screening through multiple parallel rollers with specially shaped screens that rotate in the same direction. This dynamic screening method allows the material to fully contact the screen surface, which can greatly increase the screening speed and processing capacity compared to traditional static screens. For example, in the coal screening of thermal power plants, the roller screen can process hundreds of tons of coal per hour, efficiently transporting coal that meets the particle size requirements to the boiler to ensure power generation efficiency.

The roller screen has strong adaptability to materials. Whether it is granular sand and coal, or wet coal and clay with high viscosity and easy to clog, or irregularly shaped domestic garbage, it can effectively screen. The screen shaft spacing and screen shape can be flexibly adjusted according to the characteristics of the material. For materials that are easy to entangle, it can also be equipped with anti-entanglement design screens to prevent material entanglement from affecting the screening effect. This feature makes it widely used in mining, building materials, environmental protection and other industries.

In terms of anti-clogging performance, the roller screen has obvious advantages. The rotating motion of the screen shaft can stir and push the material, and even if it encounters wet and sticky materials, it can avoid clogging of the screen holes. At the same time, the special structure of the screen plate allows the material to continuously change its direction of movement during the rolling process, reduce material accumulation, maintain the continuity and stability of screening, and do not need to stop frequently for cleaning, which greatly improves the utilization rate of the equipment.

From the maintenance point of view, the roller screen has the characteristics of simple structure and convenient maintenance. The main components of the equipment are the screen shaft and the screen plate, and the modular design is easy to disassemble and replace. Daily maintenance only requires regular inspection of the operation of the screen shaft, the degree of wear of the screen plate, and necessary lubrication and tightening. Compared with complex equipment such as vibrating screens, the roller screen has lower maintenance costs and longer maintenance cycles, which effectively reduces the operating costs of enterprises.

The roller screen has low noise and low vibration during operation, which meets the requirements of environmental protection and safe production. Its stable operating state not only reduces the impact on the surrounding environment, but also extends the service life of the equipment itself, creating more lasting economic benefits for the enterprise. With these outstanding characteristics and advantages, the roller screen has become an indispensable and efficient screening equipment in modern industrial production.

The above details the characteristics and advantages of the roller screen. If you want to know about its specific application cases in a particular industry, or a comparative analysis with other screening equipment, please feel free to let me know.

Technical Parameter Table of Roller Screen

| Model | No. of Rollers | Roller Length (mm) | Screen Gap (mm) | Capacity (TPH) | Motor Power (kW) | Application Material | Dimensions (mm) |

|---|---|---|---|---|---|---|---|

| RS-800 | 6 | 1000 | 20 – 50 | 30 | 3.0 | Coal / Sand / Biomass | 2800×1200×1300 |

| RS-1000 | 8 | 1200 | 25 – 60 | 50 | 4.0 | Construction Waste / Ore | 3200×1400×1400 |

| RS-1300 | 10 | 1500 | 30 – 70 | 80 | 5.5 | MSW / Stone / Wood Chips | 3600×1500×1500 |

| RS-1600 | 12 | 1800 | 35 – 80 | 120 | 7.5 | Mixed Waste / Biomass Fuel | 4200×1600×1600 |

| RS-2000 | 14 | 2000 | 40 – 100 | 160 | 11.0 | Ore / Municipal Waste | 4700×1800×1700 |

| RS-2500 | 16 | 2200 | 50 – 120 | 200 | 15.0 | Construction & Demolition | 5200×2000×1800 |

If you have any special requirements, we will customize according to your special needs.

Product Picture Display of Roller Screen

FAQ about Roller Screen

>What are the advantages of Roller Screen compared to other screening equipment?

Compared with traditional vibrating screens, it is not easy to clog and is particularly suitable for processing wet and sticky materials. Compared with fixed screens, it has higher screening efficiency and requires lower installation height. It runs smoothly, has low noise and low energy consumption. The equipment is relatively sturdy, has low maintenance and overhaul frequency, and has a long service life.

>Can Roller Screen handle sticky materials?

It can effectively handle sticky materials. The rotation of the roller can make the sticky materials roll and move continuously on the screen surface, reducing the adhesion and accumulation of materials at the screen holes and reducing the risk of clogging. Some roller screens are also equipped with self-cleaning devices to further clean sticky materials adhering to the screen plate.

>How to choose the right Roller Screen model?

Factors such as material characteristics (such as particle size, moisture, viscosity, hardness, etc.), processing capacity, screening accuracy, and installation space need to be considered. When the processing volume is large and the material particle size is large, choose large-size equipment; for high screening accuracy requirements, pay attention to the sieve plate design and gap adjustment function; if the installation space is limited, choose a compact model.

>Can the sieve hole size of the Roller Screen be adjusted?

The sieve hole size of some Roller Screens can be adjusted. Some equipment changes the installation spacing of the sieve plate or adopts an adjustable sieve plate structure to achieve the change of the sieve hole size to meet the screening needs of different materials. However, there are also some fixed-size equipment whose sieve hole size is determined at the factory and cannot be adjusted.

>Is the installation and commissioning of the Roller Screen complicated?

During installation, ensure that the equipment is placed horizontally, the foundation is firm, the transmission connection between the motor and the roller is accurately aligned, and the electrical system installation complies with safety regulations. During the commissioning stage, start the equipment without load first, check whether the equipment runs smoothly and whether there is abnormal noise, then gradually load the material, and adjust the roller speed, sieve plate spacing and other parameters according to the screening effect. In general, the installation and commissioning process is relatively standardized, and if it is strictly carried out according to the operating instructions, it is not difficult.

>What does daily maintenance of Roller Screen include?

Daily maintenance includes regular inspection of the wear of rollers and sieve plates, and timely replacement of severely worn parts; checking the lubrication of transmission parts (such as chains and gears) and replenishing lubricating oil; cleaning the residual materials on the surface of the equipment and the screen surface to prevent material accumulation from affecting the operation of the equipment; monitoring the vibration and noise during the operation of the equipment, and timely troubleshooting and handling of abnormalities.

>What faults may occur during the operation of Roller Screen and how to solve them?

Common faults include material blocking the sieve holes, which can be solved by adjusting the material feed speed, cleaning the sieve plate, and appropriately increasing the roller speed; abnormal rotation of the roller may be caused by motor failure, transmission component damage or roller jamming, and the motor needs to be checked, damaged parts replaced, and debris around the roller cleaned; excessive vibration of the equipment may be caused by a weak foundation, loose parts or unbalanced rollers, and the foundation needs to be reinforced, parts tightened, and roller balance adjusted.

>What is the approximate service life of Roller Screen?

Under normal use and maintenance conditions, the service life of Roller Screen is relatively long, generally up to several years to more than ten years. However, the actual service life is affected by factors such as material properties (such as hardness, corrosiveness), frequency of use, and quality of maintenance. If high-wear and high-corrosive materials are processed and maintenance is not timely, the life of the equipment will be shortened.

>Can the Roller Screen be customized to meet special needs?

Yes. The manufacturer can customize the size, material, sieve plate structure, transmission method and control system of the equipment according to the customer's special material handling requirements, site restrictions, automation requirements, etc. For example, a special sieve plate shape is designed for special materials, and the equipment specifications are increased for high-yield requirements.

>Is the energy consumption of the Roller Screen high?

Compared with some other screening equipment, the Roller Screen has lower energy consumption. Through reasonable roller design and transmission system, it effectively reduces energy consumption while ensuring efficient screening. However, energy consumption will also vary depending on the equipment model, operating parameters and material handling volume.

>What are the safety precautions for operating the Roller Screen?

Wear protective gear such as helmets and gloves during operation; do not open protective devices during operation to avoid physical contact with moving parts; check the grounding of the equipment regularly to prevent electric shock accidents; before cleaning or repairing the equipment, cut off the power supply and ensure that the equipment is completely stopped.

>What types of Roller Screen are there?

According to the drive mode, it can be divided into two types: single-axis single-motor drive and multi-axis chain combination drive. According to the purpose, it can be divided into types with different functions such as pre-screening, controlled screening, material grading, etc. According to the structural characteristics, there are also many types with different screen plate shapes (such as round, triangular, etc.) and different screen plate installation methods.