A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

What is the Mud and Stone Separator

Mud and Stone Separator is a mechanical equipment that focuses on efficiently separating solid particles such as mud and stones. It is widely used in many fields such as construction, mining, and river dredging. Its core function is to accurately separate mud and stone in the mixed material through mechanical force and physical principles to achieve resource recycling and reduce environmental pollution.

From the working principle, mud and stone separation equipment usually combines multiple technologies such as vibration, screening, and water washing. After the equipment is started, the mixed material first enters the vibrating screen, and the material is loosened and preliminarily graded through high-frequency vibration. The stones with larger particle sizes are quickly separated under the action of vibration and slide along the screen surface to the discharge port; while the mud and fine sand and gravel with smaller particle sizes pass through the sieve holes and enter the water washing stage. In the water washing area, the high-speed water flow strongly washes the material, fully dissolves the mud and separates it from the sand and gravel, and then further dehydrates it through cyclones, dewatering screens and other equipment to finally obtain a pure mixture of sand, gravel and mud and water. After the mud and water are concentrated and filtered, mud cakes and clean water are formed. Clean water can be recycled, and mud cakes are easy to transport and dispose of later.

In terms of structural design, mud and stone separation equipment mostly adopts modular design, which is mainly composed of feeding system, vibration screening system, water washing system, dehydration system and electronic control system. Each system has a clear division of labor and close cooperation. The feeding system is responsible for uniform material transportation, the vibration screening system performs preliminary screening, the water washing system strengthens the separation effect, the dehydration system ensures the cleanliness and dryness of sand and gravel, and the electronic control system realizes the automatic operation and parameter control of the equipment to ensure the efficiency and stability of the entire separation process.

Compared with traditional manual or simple separation methods, Mud and Stone Separator has significant advantages. First, the high degree of automation can greatly reduce manpower input and reduce labor intensity; second, the separation efficiency is far higher than that of manual labor, and the processing capacity can reach tens to hundreds of tons per hour, with high separation accuracy and high sand and gravel recovery rate; third, energy saving and environmental protection, through water recycling and centralized treatment of mud cakes, it reduces water resource waste and environmental pollution, which is in line with the concept of sustainable development.

Mud and stone separation equipment plays a key role in practical applications. In construction projects, it can separate and recycle sand and gravel from waste concrete and slag to make recycled aggregates; in mining, it helps with the initial sorting of ore and improves the grade of ore; in river dredging scenarios, it can effectively separate silt and stones and purify the river environment. With the continuous advancement of technology, the performance of Mud and Stone Separator will continue to be optimized, and its application scope will be further expanded, providing strong support for resource recycling and ecological environmental protection.

Operating principle of Mud and Stone Separator

Mud and Stone Separator is a device for efficient separation of mud and stone mixed materials. It is widely used in construction, mining, river dredging and other fields. Its working principle integrates a variety of physical separation technologies to ensure the accurate separation of mud and stone.

The principle of vibration screening is a common basic technology for mud and stone separators. A specially designed vibrating screen is installed inside the equipment. When the mixed material enters the separator, the vibration motor generates high-frequency vibration, driving the screen to shake rapidly. Larger particles such as stones jump on the screen and move along the screen surface due to their large mass and inertia, and are finally discharged from the end of the screen; while mud and fine particles are smaller than the screen holes, and pass through the screen under the action of vibration and enter the collection device below. By adjusting the vibration frequency and amplitude, the screening efficiency can be optimized to adapt to mixed materials of different particle sizes.

The spiral grading principle also plays an important role in some mud and stone separators. Spiral blades are installed inside the equipment. When the material enters the separator, the spiral blades rotate slowly driven by the motor. Mud and smaller particles have good fluidity and will settle to the bottom of the separator and be pushed to the outlet by the spiral blades for discharge; large particles such as stones are deposited at the bottom due to gravity, gradually move upwards as the spiral blades rotate, and finally separated from the higher outlet. This method utilizes the difference in material density and fluidity to achieve a continuous and stable separation process.

In addition, some mud and rock separators also use hydrocyclone separation technology. After the mixed material enters the cyclone together with water, under the centrifugal force generated by high-speed rotation, materials with higher density such as stones are thrown to the inner wall of the cyclone, and move downward along the inner wall and discharged from the bottom outlet; mud and particles with lower density gather toward the center of the cyclone due to the smaller centrifugal force, and flow out from the top overflow port to complete the separation. This technology is particularly suitable for processing mixed materials with fine particles and high mud content, with high separation efficiency and low energy consumption.

In practical applications, in order to achieve the best separation effect, mud and rock separators often combine multiple separation principles. For example, first remove larger stones through vibration screening, and then use spiral classification or hydrocyclone technology to further separate fine particles and mud, so as to achieve multi-level and precise separation of mixed materials and meet the processing requirements under different working conditions.

Mud and Stone Separator uses the principles of vibration screening, spiral classification, hydrocyclone, and the synergy of multiple technologies to efficiently separate mud and stones, solving material handling problems for related industries and improving resource utilization efficiency and environmental protection of construction production.

Advantages and features of Mud and Stone Separator

Mud and Stone Separator is a professional equipment developed to solve the problem of separating mud and stones in solid-liquid mixed materials. It has shown remarkable characteristics and advantages in the fields of construction, mining, environmental protection, etc.

Efficient separation is the primary advantage of Mud and Stone Separator. The equipment adopts advanced mechanical separation technology, combined with multiple principles such as vibration screening, centrifugal separation or cyclone separation, to quickly and accurately separate mud and stones. In the construction of building piling, it can quickly handle a large amount of mud mixture generated by construction, efficiently separate solid particles such as stones and gravel, purify the mud, and solid materials can also be classified and recycled, which greatly improves the construction efficiency and avoids construction delays caused by material accumulation.

Its strong adaptability is also remarkable. Whether it is extremely viscous clay mud or complex mixed materials containing large-size stones, Mud and Stone Separator can flexibly respond to various working conditions by adjusting equipment parameters and replacing screens or components of different specifications. In the mining scenario, the mud produced by the mine pit has complex composition and stones of different sizes. With its adjustable separation system, the equipment can adapt to muds of different concentrations and different stone contents to ensure stable separation.

Mud and Stone Separator also has significant environmental benefits. By effectively separating mud and stones, the pollution of soil and water bodies caused by random discharge of mud is reduced. At the same time, the separated solid materials can be further processed and utilized to achieve resource recycling. For example, in the river dredging project, the mud treated by the equipment can be discharged after purification, and the separated stones and silt can be used for road paving or brick making, reducing the pressure of waste on the environment and practicing the concept of green construction.

From the perspective of equipment maintenance, the Mud and Stone Separator has a scientific and reasonable design, compact structure and easy disassembly. The key components are made of wear-resistant and corrosion-resistant materials, which prolongs the service life of the equipment; the modular design makes daily maintenance and troubleshooting more convenient. Once a problem occurs, maintenance personnel can quickly locate and replace damaged parts, reduce equipment downtime and reduce maintenance costs.

The equipment has a high degree of automation and is equipped with an intelligent control system, which can monitor the equipment's operating status and separation effect in real time. Operators can adjust the equipment's operating parameters through the control system according to actual needs, achieving unmanned or less-manned operation, which not only improves production efficiency, but also reduces manual operation intensity and human errors.

Mud and Stone Separator provides reliable material handling solutions for related industries with its advantages of efficient separation, strong adaptability, environmental protection and energy saving, simple maintenance and high degree of automation, and promotes engineering construction and resource development to a more efficient and greener direction.

Technical Parameter Table of Mud and Stone Separator

| Model | Max Capacity (TPH) | Screen Aperture (mm) | Pump Power (kW) | Separation Efficiency (%) | Dimensions (mm) | Weight (kg) |

|---|---|---|---|---|---|---|

| MSS-500 | 20 | 5 – 20 | 3.0 | 85 | 3000×1000×1300 | 1500 |

| MSS-800 | 40 | 10 – 30 | 4.0 | 88 | 3500×1200×1400 | 2000 |

| MSS-1000 | 60 | 15 – 40 | 5.5 | 90 | 4000×1400×1500 | 2500 |

| MSS-1500 | 100 | 20 – 50 | 7.5 | 92 | 4500×1600×1600 | 3200 |

| MSS-2000 | 150 | 30 – 60 | 11.0 | 95 | 5000×1800×1700 | 4500 |

| MSS-2500 | 200 | 40 – 80 | 15.0 | 98 | 5500×2000×1800 | 6000 |

If you have any special requirements, we will customize according to your special needs.

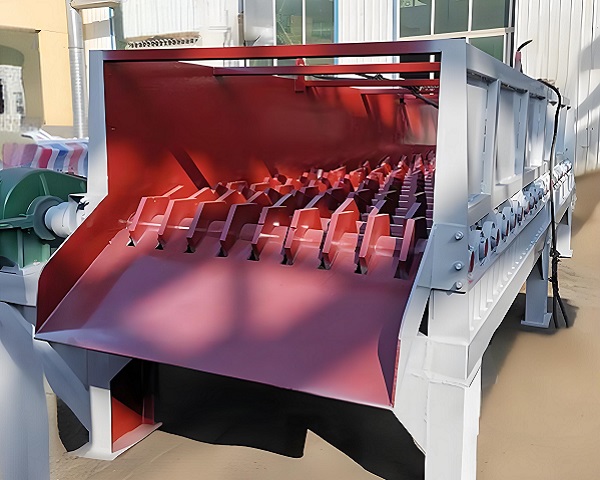

Product Picture Display of Mud and Stone Separator

FAQ about Mud and Stone Separator

>How to determine the processing capacity of Mud and Stone Separator?

The processing capacity mainly depends on the size of the equipment, including the number, length, diameter and overall size of the rollers. Large equipment has many rollers and large size, and has a strong processing capacity, which can reach hundreds or even thousands of tons per hour; small equipment is suitable for working conditions with smaller processing volume. In addition, material properties such as particle size distribution, humidity, viscosity, etc. will also affect the processing capacity. Generally speaking, materials with uniform particles, low humidity and low viscosity can be processed faster.

>How to choose a suitable Mud and Stone Separator?

It is necessary to comprehensively consider the material properties, such as the proportion of mud and stone in the material, the particle size range, humidity, viscosity, etc., to determine the key parameters of the equipment such as the roller gap and material (corrosion-resistant materials should be selected for corrosive materials). At the same time, the equipment specifications should be determined in combination with the processing volume requirements. The site space will also affect the equipment selection. If the site is limited, a compact equipment with a small footprint can be selected. In addition, the brand reputation and after-sales service quality of the equipment are also important reference factors.

>Will the Mud and Stone Separator generate noise and dust during operation? How to solve it?

Some noise and dust may be generated during operation. The noise mainly comes from the rotation of the motor and roller and the friction between the material and the equipment parts. The noise can be reduced by selecting low-noise motors, shock-absorbing the equipment (such as installing shock-absorbing pads), and adding sound insulation materials to the equipment shell. In terms of dust, spray dust suppression devices can be installed at the feed port, discharge port and inside the equipment, dust collection hoods can be installed above the equipment, and dust removal equipment such as pulse bag dust collectors can be connected to collect and treat dust to reduce dust emissions.

>Is the maintenance of Mud and Stone Separator complicated? What should be paid attention to?

The maintenance is relatively simple. Daily check the rotation of the roller to ensure that it is flexible and free of jams, and clean up the debris wrapped around the roller in time; check the running status of the motor regularly, add lubricating oil on time to prevent the motor from overheating and damage; pay attention to the wear of various parts of the equipment, especially the discs, blades and other wearing parts on the rollers, and replace them in time when they are severely worn. At the same time, ensure that the electrical system of the equipment is normal to prevent short circuits, leakage and other faults.

>Can Mud and Stone Separator handle wet and sticky materials?

Yes. Some mud and stone separators are specially designed for wet and sticky materials, such as using specially shaped roller blades to increase the friction between the material and the blades to prevent the material from sticking; strengthening the vibration function of the equipment to assist the material to slide through vibration; some are also equipped with heating devices to appropriately reduce the viscosity of the material to ensure that when handling wet and sticky materials, a good separation effect can still be maintained.

>Is it difficult to install and debug Mud and Stone Separator?

Installation and debugging work requires professional personnel to operate, but the overall difficulty is not too great. During installation, the equipment needs to be placed stably on a solid foundation to ensure that the level meets the standard, and then the roller, motor, transmission device, collection device and other components are connected in turn to ensure that each component is firmly connected. During the debugging stage, start the equipment without load first, check whether the motor direction is correct, whether the roller rotates smoothly, and whether there is abnormal noise and vibration. Then gradually load the material, and fine-tune the roller gap, motor speed and other parameters according to the separation effect of the material until the best working state is achieved.

>What faults may occur during the operation of Mud and Stone Separator and how to solve them?

Common faults include roller jamming, which may be caused by material entanglement or bearing damage. It is necessary to clean the entanglement and check and replace the bearings; motor overheating may be caused by overload and poor heat dissipation. The load can be reduced and the motor cooling fan and vents can be cleaned; if the separation effect is not good, if the roller gap is not appropriate, the gap can be adjusted. If it is caused by problems such as material humidity, auxiliary drying and vibration can be used to improve it. In addition, the transmission chain may become loose or fall off, and the chain needs to be adjusted and repaired in time.

>Can the Mud and Stone Separator be customized to meet special needs?

In most cases, it can be customized. Manufacturers can customize the structure, size, material, degree of automation, etc. of the equipment according to the customer's special material characteristics (such as extremely fine particles, highly corrosive materials), special site conditions (such as narrow space, low plant), special processing requirements (super-large or super-small processing scale), etc. For example, to adapt to low plants, low-profile equipment is designed; for corrosive materials, corrosion-resistant stainless steel is selected to make key components.

>Does the Mud and Stone Separator consume a lot of energy?

The energy consumption is related to the power, running time and material handling capacity of the equipment. Generally speaking, the energy consumption of mud and stone separators using advanced energy-saving technology and high-efficiency motors is relatively reasonable. By optimizing the equipment structure, reducing unnecessary power loss, and reasonably adjusting the equipment operating parameters, it can reduce energy consumption while working efficiently. Compared with some traditional equipment with large processing capacity but low efficiency, the new Mud and Stone Separator performs better in energy consumption control.

>How does the Mud and Stone Separator separate construction waste of different components in construction waste treatment?

It performs well in construction waste treatment. It has a significant effect on separating stones, bricks and other light debris such as soil, gypsum, wood chips and plastics in construction waste. By reasonably setting the roller gap and operating parameters, different components can be accurately separated. For example, larger stones can be effectively separated from fine soil particles, and light plastics, fibers and other garbage mixed in them can be screened out, providing a good foundation for the subsequent classification and recycling of construction waste.

>How long is the service life of Mud and Stone Separator?

Under normal use and maintenance conditions, the equipment has a long service life. If key components such as rollers, motors, transmission devices, etc. are made of high-quality materials and are properly maintained on a daily basis, the equipment can operate stably for 5-10 years or even longer. However, the actual service life is affected by factors such as material properties (such as material hardness and corrosiveness), frequency of use, and quality of maintenance. Frequent use under harsh working conditions and untimely maintenance will shorten the service life of the equipment accordingly.

>Compared with other types of mud and stone separation equipment, what is unique about Mud and Stone Separator?

The uniqueness of Mud and Stone Separator lies in its roller screening structure. Compared with equipment such as vibrating screens, it has better adaptability to wet and sticky materials and is not easy to clog the screen. Compared with spiral separators, the equipment structure is relatively simple and the maintenance cost is low. At the same time, its separation accuracy can be flexibly controlled by adjusting the roller gap, which can adapt to the separation needs of various complex materials, and has obvious advantages in processing large particles.

>What is the working principle of Mud and Stone Separator?

Mud and Stone Separator, or mud and stone separator, usually adopts the principle of roller screening. The roller in the equipment is driven by a motor to rotate, and a special disc or blade is installed on the roller. After the material enters the equipment, it moves forward driven by the roller. Due to the gap between the disc or blade, the mud and fine particles smaller than the gap size will fall from the gap and be taken away by the collection device below; while the stones larger than the gap size are transported to the end of the equipment along the surface of the roller and discharged, so as to achieve efficient separation of mud and stone.

>What fields are Mud and Stone Separator mainly used in?

It is widely used in many fields. In mining, it is used for the preliminary separation of mud and stone mixed materials after the original ore is mined to reduce the processing pressure of subsequent crushing and mineral processing equipment; in the production of sand and gravel aggregates, it is used to separate the soil impurities in the sand and gravel raw materials to improve the quality of sand and gravel; in the field of construction waste treatment, the stones in the construction waste can be separated from the soil and light waste, which is convenient for subsequent resource utilization; in addition, it is also used in scenes involving mud and stone separation such as agriculture and river dredging.

>What are the advantages of Mud and Stone Separator compared to other mud and stone separation methods?

Compared with other separation methods such as water washing, Mud and Stone Separator does not require a large amount of water resources, can work in water-scarce areas or scenarios with limited water use, and avoids environmental problems caused by sewage discharge. Compared with manual sorting, it has a high degree of automation and a large processing volume, which can greatly improve work efficiency and reduce labor costs. At the same time, the equipment has a high separation accuracy and can adapt to different material characteristics by adjusting parameters such as roller gap.