A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

What is the Disc Separator

Disc Separator is an efficient material screening, classification and separation equipment. With its unique structure and working principle, it plays a key role in many industries.

Structurally, the disc screen is mainly composed of motor, screen frame, screen plate, shaft and sprocket. The motor is the power source and provides driving force for the operation of the equipment. The screen frame is a supporting structure, on which a feed hopper, a qualified material drop hopper and a large-size material drop hopper are arranged. The screen plate is usually polygonal and installed on parallel shafts. Sprockets are fixed at the ends of the shafts, and the shafts are driven by chains to achieve synchronous rotation of each shaft. The disc in the middle of the shaft forms a sieve hole between the screen plate and the shaft, so that the material can be screened and graded.

When the disc screen is working, the motor starts, driving the sprocket on the shaft to rotate, and each shaft and the disc on it rotate synchronously in the same direction. The materials to be screened enter the feed hopper evenly. Under the action of the rotating disc, materials smaller than the size of the sieve holes, under the action of gravity and centrifugal force, pass through the sieve holes and fall into the qualified material drop hopper; while materials larger than the size of the sieve holes continue to move along the screen surface driven by the disc, and finally discharged from the large-size drop hopper, thereby achieving accurate separation of materials of different particle sizes.

In terms of application, the disc screen performs very well. In the food processing industry, it can screen raw materials such as grains, beans, and nuts to remove impurities and ensure product quality and hygiene standards; in the mining and metallurgical fields, it can grade materials such as ores, coal, and coke to assist in subsequent refining and processing; in the chemical and plastic industries, it can screen chemical raw materials, plastic particles, etc. to ensure product purity and uniformity; in agriculture and forestry, it can be used to screen seeds, fertilizers, wood, etc. to improve production efficiency and product quality; in the pharmaceutical industry, it can screen pharmaceutical raw materials and intermediates to ensure the safety and effectiveness of drugs.

Compared with traditional screening equipment, the disc screen has obvious advantages. First, the self-cleaning function is strong. The rotating screen disc can prevent the material from sticking and clogging the screen hole. Especially when dealing with sticky materials or garbage, it can reduce the frequency of shutdown for cleaning and improve production continuity. Second, the screening efficiency is high, and the processing capacity can reach several times that of traditional equipment. For example, in the field of garbage sorting, its processing capacity is 4 times that of the same specification drum screen, and the screening efficiency is 2 times. Third, it has wide adaptability. It can meet the requirements of different materials and screening accuracy by adjusting the screen disc spacing, screen hole size and equipment speed, and the modular design makes the equipment easy to maintain and replace parts.

The disc screen has become an ideal choice for material screening in many industries with its high efficiency, stability and strong adaptability, providing strong support for efficient production and product quality improvement in various industries.

Operating principle of Disc Separator

Disc Separator is a device that achieves efficient separation based on the difference in physical properties of materials. It is widely used in the fields of ore selection, metal recovery and industrial waste treatment. Its working principle relies on the synergy of unique structural design and physical field, and can accurately separate materials with different magnetic properties, electrical properties or densities.

The core structure of the disc separator consists of one or more sets of parallel discs, a transmission system, a physical field generating device (such as a magnetic system or electrode) and a collection tank. The surface of the disc is usually covered with special materials (such as wear-resistant rubber or magnetic coating) to enhance the adsorption or repulsion of the target material. When working, the disc rotates at a constant speed driven by a motor to form a continuous material processing surface.

In the magnetic separation type Disc Separator, its sorting principle is based on the difference in material magnetism. The built-in magnetic system (permanent magnet or electromagnetic coil) of the equipment generates a high-intensity magnetic field. When a mixed material containing magnetic minerals (such as magnetite, hematite) enters the sorting area, the magnetic particles are attracted by the magnetic field force, adsorbed to the surface of the disc, and leave the magnetic field action area as the disc rotates. After the disc is separated from the magnetic field, the magnetic particles fall off due to gravity or auxiliary unloading devices (such as brush rollers, airflow) and fall into the collection tank, while non-magnetic or weakly magnetic materials are directly discharged under the action of gravity and centrifugal force to achieve separation.

For the disc separator of the electrostatic type, the working principle is based on the difference in the conductivity of the material. The equipment generates a high-voltage electrostatic field through electrodes. When the material enters the electric field area, the particles with good conductivity quickly absorb the charge and induce with the surface of the disc, and are adsorbed on the disc. After the disc rotates to the unloading area, the charge is released through the grounding device and falls off and collected; non-conductive or weakly conductive materials cannot effectively absorb the charge, and are directly discharged under the action of gravity and centrifugal force, thus completing the separation.

Some disc separators also combine density differences for sorting. The centrifugal force generated by the rotation of the disc and gravity work together to make the material with higher density closer to the surface of the disc, and produce a difference in separation path with the material with lower density during the movement, and finally enter different collection areas.

Disc Separator achieves efficient separation of complex mixed materials through ingenious design and flexible application of physical fields. Its accuracy and reliability make it an indispensable key equipment in modern industrial material processing. With the development of technology, new disc separators continue to optimize magnetic system structure, electric field distribution and automation control level, further improving separation efficiency and adaptability.

Advantages and features of Disc Separator

With its unique structural design and working principle, Disc Separator has shown significant characteristics and advantages in the field of resource sorting and has become a key equipment for efficient material processing.

Its core feature lies in its efficient sorting ability. The disc separator uses a disc with magnetic or special adsorption materials to fully contact the material during rotation, and uses magnetic force or physical adsorption principles to quickly and accurately separate the target material from the mixed material. In the metal recycling industry, mixed ferromagnetic metals and non-magnetic materials can be efficiently separated, greatly improving the recycling efficiency and metal purity; in the field of mineral processing, ores with magnetic differences can also be effectively sorted to help extract high-value minerals.

Disc Separator has strong adaptability and can handle a variety of materials. Whether it is granular, powdery materials, or irregularly shaped waste, the device can respond flexibly. By adjusting the rotation speed of the disc, the magnetic field strength or the characteristics of the adsorption material, it can adapt to the sorting needs of materials of different properties. In the treatment of electronic waste, copper, iron, aluminum and other metals can be accurately separated according to the type and property of the metal to meet the diverse sorting requirements.

The equipment's operational stability and low maintenance requirements are also outstanding advantages. Its structural design is simple and compact, and the core component disc is made of wear-resistant and corrosion-resistant materials, reducing the risk of wear and failure. In addition, the operation process of the disc separator is relatively simple, without complex mechanical transmission structure, which reduces maintenance frequency and cost. Even under long-term continuous operation conditions, it can maintain stable sorting performance, saving a lot of manpower and maintenance resources for the company.

The equipment also has good environmental protection characteristics. During the sorting process, materials are separated based on physical principles without the use of chemical agents, avoiding environmental pollution problems. At the same time, the efficient sorting function improves the resource recovery rate, reduces waste emissions, conforms to the concept of sustainable development, and helps the development of the circular economy.

The Disc Separator has a high degree of automation and can be linked with other production equipment. Equipped with advanced sensors and control systems, it can monitor the sorting effect in real time, automatically adjust the operating parameters, and ensure sorting accuracy and efficiency. This not only reduces the intensity of manual operation, but also improves the intelligence level of the production process, adapting to the needs of modern industrial production.

With the advantages of efficient sorting, wide adaptability, stability and durability, green environmental protection and automation, Disc Separator plays an important role in many industries and provides strong support for efficient resource utilization and sustainable development.

Technical Parameter Table of Disc Separator

| Model | Disc Diameter (mm) | No. of Discs | Separation Speed (RPM) | Capacity (TPH) | Motor Power (kW) | Separation Precision (%) | Dimensions (mm) |

|---|---|---|---|---|---|---|---|

| DS-300 | 300 | 20 | 1450 | 1.5 | 1.1 | 90 | 1200×600×800 |

| DS-500 | 500 | 30 | 1500 | 3.0 | 2.2 | 92 | 1500×800×900 |

| DS-800 | 600 | 40 | 1600 | 5.5 | 3.0 | 94 | 1800×900×1100 |

| DS-1000 | 700 | 50 | 1700 | 8.0 | 4.0 | 95 | 2000×1000×1200 |

| DS-1500 | 800 | 60 | 1750 | 12.0 | 5.5 | 96 | 2200×1100×1300 |

| DS-2000 | 1000 | 80 | 1800 | 18.0 | 7.5 | 98 | 2500×1200×1400 |

If you have any special requirements, we will customize according to your special needs.

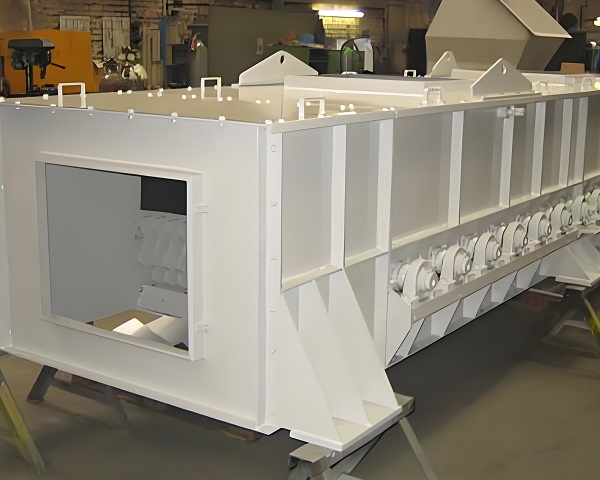

Product Picture Display of Disc Separator

FAQ about Disc Separator

>What fields are Disc Separators mainly used in?

It is widely used in mining to separate metal ores such as copper, iron, and manganese; in the food industry, it is used to sort nuts, grains, and seeds; in the environmental protection field, it treats sewage and separates sludge and clean water; in the plastic recycling industry, it sorts plastics of different materials according to density differences; it is also used for material separation in industries such as chemical raw materials and building materials.

>What are the characteristics of Disc Separators of different materials?

Stainless steel is corrosion-resistant and suitable for fields with high hygiene requirements such as food and medicine; carbon steel is low-cost and high-strength, and is often used in mining, building materials and other scenes that do not require high corrosion resistance; ceramic materials are wear-resistant and acid-resistant, and are suitable for processing high-hardness and highly corrosive materials such as ores and chemical raw materials.

>How to choose a suitable Disc Separator model?

It needs to be considered comprehensively based on material characteristics (density, particle size, magnetism, etc.), processing volume, separation accuracy and budget. For processing volume, large-diameter and high-speed models are selected; for high separation accuracy requirements, attention should be paid to the disc structure design; for processing corrosive materials, corrosion-resistant material models are preferred.

>What factors affect the separation efficiency of Disc Separator?

The separation efficiency is affected by factors such as disc speed, material feed speed and concentration, disc surface structure, and material properties. The higher the speed, the greater the centrifugal force, but too high a speed can easily cause material splashing; uniform and stable feeding and moderate concentration can improve efficiency; the disc surface structure is adapted to the material characteristics, which can enhance the separation effect.

>What matters need to be paid attention to when installing Disc Separator?

During installation, it is necessary to ensure that the equipment is placed horizontally to avoid unstable operation due to tilting; the connection between the motor and the disc must be accurately aligned to ensure smooth transmission; the electrical system installation complies with safety regulations and is well grounded; sufficient maintenance space is reserved for later maintenance.

>What does daily maintenance of Disc Separator include?

Daily maintenance includes regular cleaning of residual materials on the surface of the disc to prevent blockage and corrosion; checking the lubrication of the motor and transmission parts, and replenishing lubricating oil in time; monitoring the vibration and noise of the equipment during operation, and stopping the machine for inspection in time if abnormalities are found; regular calibration of separation parameters to ensure stable separation effect.

>How to troubleshoot Disc Separator failures?

If the separation effect is not good, check whether the feed is uniform and the disc speed is normal; if the equipment vibrates abnormally, check whether the anchor bolts are loose and whether the disc is balanced; if the motor is overheated or has abnormal noise, it may be insufficient lubrication or component wear. Check the lubrication system and wear parts and deal with them in time.

>Can Disc Separator handle sticky materials?

It is usually not suitable for handling highly sticky materials because they are easy to adhere to the surface of the disc, causing blockage, affecting the separation effect and equipment operation. If treatment is required, the material can be pre-treated (such as drying, diluting), or a specially designed device (such as a scraper device) can be selected.

>Is the energy consumption of Disc Separator high?

Energy consumption is related to the equipment model and operating parameters. Large-scale, high-speed equipment has relatively high energy consumption, but energy consumption can be reduced by optimizing the disc design, using high-efficiency motors and intelligent control systems. In actual operation, reasonable control of feed volume and speed can effectively save energy.

>What is the service life of Disc Separator?

Under normal use and maintenance, the equipment service life can reach 5-10 years. However, due to factors such as material characteristics (wear, corrosion degree), frequency of use, and maintenance quality, handling highly abrasive materials or improper maintenance will shorten the life of the equipment.

>Can Disc Separator be customized?

Yes. Manufacturers can customize the disc material, size, speed, surface structure, and degree of automation according to customer needs. For example, for special material separation needs, design a unique disc groove shape or magnetic configuration; for high processing capacity needs, increase equipment specifications.

>What are the advantages of Disc Separator compared to other separation equipment?

Compared with traditional screening and sedimentation equipment, it has higher separation efficiency and can handle finer particles; compared with centrifugal separators, it has a simple structure and convenient maintenance, and is suitable for a variety of materials; compared with conventional magnetic separation equipment, magnetic separation Disc Separator has higher separation accuracy and can operate continuously.

>What are the safety precautions for operating Disc Separator?

Wear protective gear during operation to prevent material splashing and injuring people; do not open the protective cover when the equipment is running; check the grounding of the equipment regularly to prevent electric shock; be sure to cut off the power supply before cleaning or repairing the equipment, and wait until the equipment stops rotating completely before operating.

>What is a Disc Separator?

Disc Separator is a disc separator, which is a device that separates mixed materials by rotating discs using centrifugal force, density difference or magnetic principle. The specially designed grooves, blades or magnetic coatings on the surface of the disc, combined with high-speed rotation, can accurately separate particles or fluids with different characteristics, and are widely used in industries, environmental protection and other fields.

>What is the working principle of Disc Separator?

Its working principle is based on centrifugal force and material property differences. After the mixed material enters the rotating disc, it moves to the edge of the disc under the action of centrifugal force. Particles with high density and large particle size are subjected to greater centrifugal force and are thrown out along the outside of the disc; particles with low density and small particle size are discharged from the inside. If used for magnetic separation, the disc with magnetic parts adsorbs magnetic materials to separate magnetic and non-magnetic materials.