A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

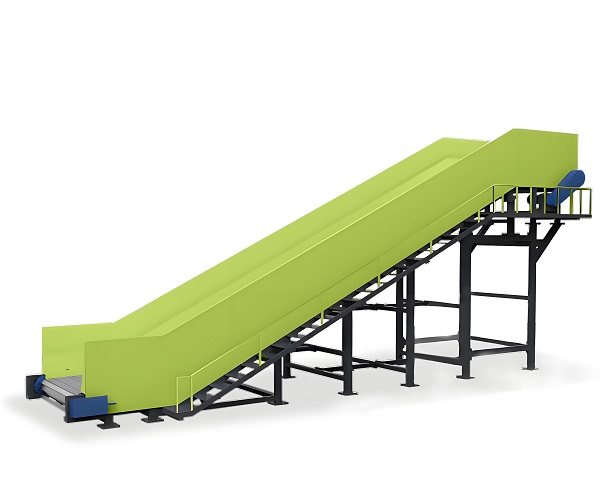

What is the Chain Plate Conveyor

A Chain Plate Conveyor, a crucial piece of equipment in modern industrial material handling, is designed to transport various materials efficiently and reliably. It operates on the principle of a chain-driven system, with metal plates attached to the chains, providing a sturdy and continuous surface for conveying items.

The structure of a Chain Plate Conveyor mainly consists of a drive unit, chains, plates, idlers, and a frame. The drive unit, usually powered by an electric motor and a reducer, initiates the movement. High-strength chains, which are the core of the conveying mechanism, are connected to the drive sprockets and run along the track formed by idlers. The plates, firmly attached to the chains, form a flat and stable conveying surface. The frame provides structural support and ensures the overall stability of the conveyor.

This type of conveyor offers several significant advantages. Firstly, it boasts a high load - bearing capacity. The robust chain and plate structure enable it to handle heavy - duty materials, such as large machine parts, heavy packages, and bulk items like stones or metals, which other conveyors may struggle to transport. Secondly, its durability is remarkable. Made from wear - resistant materials, the chains and plates can withstand harsh operating conditions, including high temperatures, corrosive environments, and abrasive materials, reducing maintenance frequency and extending the service life. Additionally, the Chain Plate Conveyor allows for smooth and continuous transportation, minimizing the risk of material jams or spills, which is crucial for maintaining production efficiency.

Chain Plate Conveyors are widely used across multiple industries. In the automotive manufacturing industry, they are employed to transport engine blocks, chassis components, and other large parts between different production stations. In the food processing industry, hygienic versions of these conveyors, made from food - grade materials, are used to move packaged goods, ensuring product safety and integrity. In the mining and construction industries, they handle bulk materials like ores, gravels, and sand, facilitating the movement of materials from extraction sites to processing areas or storage locations.

The Chain Plate Conveyor plays an indispensable role in industrial material handling. With continuous technological advancements, it is evolving to become more intelligent, energy - efficient, and adaptable, meeting the ever - changing demands of modern industries.

Operating principle of Chain Plate Conveyor

Chain Plate Conveyor is a mechanical equipment that relies on chain traction and chain plates to carry materials for continuous conveying. It is widely used in food processing, chemical, metallurgy, logistics and other industries. Its working principle is based on mechanical transmission and structural coordination, and can efficiently and stably complete the horizontal or inclined conveying of materials.

The core components of the chain plate conveyor include the drive device, chain, chain plate, tensioning device and frame. The drive device is usually composed of a motor, a reducer and a sprocket. The motor provides power, and after the speed is reduced and the torque is increased by the reducer, the sprocket is driven to rotate. The chain is wrapped around the drive sprocket and the tensioning sprocket to form a closed loop, which is a key component for transmitting power and pulling the chain plate. The chain plate is connected to the chain through the chain link to form a working surface for carrying materials. Its material and structure are determined according to the characteristics of the conveying material, such as food-grade stainless steel chain plates for food conveying, and high-strength carbon steel chain plates for heavy-duty industrial material conveying. The tensioning device can adjust the tightness of the chain to ensure that the chain and sprocket maintain a good meshing state to prevent slipping.

When the equipment is started, the motor of the drive device runs, and the power is transmitted through the reducer to rotate the drive sprocket, thereby driving the chain to circulate on the frame. The chain plate moves with the chain to form a continuous material conveying channel. The material is placed on the chain plate, and under the dual effects of friction and chain plate movement, it moves forward with the chain plate. During the conveying process, if the conveying direction of the material needs to be changed or sorted, it can be achieved by setting up bends, diversion devices, etc. When the material is conveyed to the designated location, it is unloaded by gravity or a discharge device.

During the entire working process, the various components cooperate with each other, the drive device provides power, the chain transmits power, the chain plate carries the material, the tensioning device ensures the stable operation of the chain, and the frame plays a supporting and fixing role, which together ensures that the chain conveyor can efficiently and reliably complete the material conveying task.

Advantages and features of Chain Plate Conveyor

The Chain Plate Conveyor is a mechanical equipment that uses metal chain plates as load-bearing components and realizes continuous material transportation through chain traction. In the fields of industrial production, logistics and transportation, its unique characteristics and significant advantages make it a popular conveying equipment.

In terms of structure and performance, the Chain Plate Conveyor has a strong load-bearing capacity. The chain plate is made of high-strength metal material and can withstand the transportation of heavy weight and large volume materials, such as mine ores, large machinery parts, etc., and performs well in heavy industrial scenes. Its operation is stable and reliable. The chain transmission system has been precisely designed and processed, with high transmission efficiency. It is not easy to slip, run off the track and other problems. It can operate continuously for a long time, greatly reducing the frequency of downtime maintenance and ensuring production continuity.

In terms of conveying characteristics, the Chain Plate Conveyor has extremely wide adaptability. It can convey bulk materials in block and granular form, as well as piece items, and the conveying speed can be adjusted according to the characteristics of the material; the conveying line is flexible and changeable, and can realize horizontal, inclined or even vertical conveying. It can also be designed into a variety of conveying forms such as straight lines, turns, and rings according to the layout of factory workshops, warehouses and other sites, effectively saving space and improving site utilization.

The Chain Plate Conveyor also has the advantage of being easy to maintain and clean. Its chain plate has a simple structure and is easy to disassemble and install. If it is damaged, a single chain plate can be quickly replaced to reduce maintenance costs. The surface is flat and smooth, and it is not easy for materials to adhere. It is very convenient to clean, especially suitable for industries with high hygiene requirements such as food and medicine. At the same time, the equipment has low operating noise, which reduces interference with the working environment and conforms to the modern green production concept. With these characteristics and advantages, the Chain Plate Conveyor continues to play an important role in various production scenarios, providing reliable guarantee for efficient material transportation.

Technical Parameter Table of Chain Plate Conveyor

| Specification / Model | CP400 | CP600 | CP800 | CP1000 |

|---|---|---|---|---|

| Chain Plate Width | 400 mm | 600 mm | 800 mm | 1000 mm |

| Conveyor Length | 2–30 m | 2–50 m | 2–60 m | 2–80 m |

| Conveyor Speed | 0.5–15 m/min | 0.5–15 m/min | 0.5–20 m/min | 0.5–20 m/min |

| Load Capacity | ≤200 kg/m | ≤300 kg/m | ≤500 kg/m | ≤800 kg/m |

| Plate Material | Carbon Steel / Stainless Steel | Carbon Steel / Stainless Steel | Stainless Steel | Stainless Steel |

| Drive Method | Motor + Gear Reducer Direct Drive | Motor + Sprocket & Chain | Motor + Chain Drive | Motor + Chain Drive |

| Operating Temperature | -10°C to 150°C | -10°C to 200°C | -10°C to 250°C | -10°C to 300°C |

| Applications | Food, Packaging, Small Parts | Electronics, Assembly Line | Metallurgy, Heat Treatment | Heavy-duty Automated Conveying |

If you have any special requirements, we will customize according to your special needs.

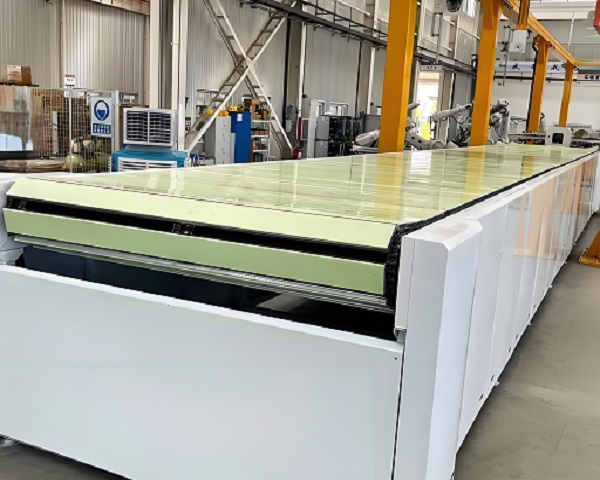

Product Picture Display of Chain Plate Conveyor

FAQ about Chain Plate Conveyor

>What types of Chain Plate Conveyors are there?

According to the structure, it can be divided into flat-top Chain Plate Conveyors, side-bend Chain Plate Conveyors, climbing Chain Plate Conveyors, etc.; according to the drive mode, it can be divided into motor drive and hydraulic drive; according to the chain material, there are stainless steel, carbon steel, plastic steel and other types to meet the needs of different working conditions.

>What is the working principle of the Chain Plate Conveyor?

The motor drives the reducer to drive the sprocket to rotate, and the sprocket engages with the chain on the chain plate, so that the chain plate circulates on the guide rail, thereby realizing the horizontal, inclined or vertical conveying of materials, and the operation is stable and reliable.

>What materials are suitable for Chain Plate Conveyors?

Suitable for conveying various types of high-temperature, sharp, heavy and other materials, such as bread and biscuits in food processing, granular raw materials in the chemical industry, ore and coal in mines, and parts in machinery manufacturing.

>What are the advantages of Chain Plate Conveyors?

It has the characteristics of large conveying capacity, stable operation, long service life and convenient maintenance; the conveying length, width and conveying form can be customized according to needs, high temperature resistance, corrosion resistance, and can adapt to harsh working environments.

>How to install and debug the Chain Plate Conveyor?

During installation, ensure that the frame is level, the sprocket and chain are properly meshed, and the chain is firmly connected; during the debugging stage, check the running speed and chain tightness, test the no-load and load running status, and ensure that the equipment runs smoothly without abnormalities.

>How to maintain the Chain Plate Conveyor on a daily basis?

Regularly check the chain tension and adjust it in time; lubricate the chain, sprocket and other transmission parts; clean the chain and the material residue on the frame; check whether the chain and chain are worn or broken, and repair and replace them in time if problems are found.

>How to troubleshoot the Chain Plate Conveyor failure?

If there is a jam in the operation, check whether there is a foreign object stuck, the chain is too tight or the sprocket is worn; if the conveying speed is abnormal, check the motor, reducer and transmission parts; if the chain is off, adjust the guide rail or tensioning device.

>How to adjust the conveying speed of the Chain Plate Conveyor?

Usually, the motor speed is adjusted by the frequency converter to change the running speed of the Chain Plate Conveyor; the speed can also be adjusted by replacing the reducer with different transmission ratios or adjusting the number of sprocket teeth.

>How to choose the material of the Chain Plate Conveyor?

The food industry needs to use stainless steel or non-toxic plastic steel that meets food hygiene standards; corrosion-resistant stainless steel or special coating materials should be selected for chemical and corrosive environments; high-strength carbon steel or heat-resistant alloy materials are used for conveying heavy objects or high-temperature materials.

>What is the future development trend of Chain Plate Conveyors?

In the future, it will develop in the direction of intelligence, energy saving and multi-functionality, integrate Internet of Things technology to realize remote monitoring and fault warning, optimize the drive system to reduce energy consumption, and develop new Chain Plate Conveyors that can realize sorting, cleaning and other multi-functional integration.