A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

What is the Belt Conveyor

Belt Conveyor is a mechanical device that uses conveyor belt as traction and load-bearing component to realize continuous material transportation. With its high efficiency, stability, energy saving and other characteristics, it is widely used in the global industrial field and has become an important part of the modern logistics and transportation system.

Structurally, Belt Conveyor is mainly composed of conveyor belt, drive device, roller, roller, tensioning device and frame. The conveyor belt is the core component. Common materials include rubber, plastic, canvas, etc. The appropriate type can be selected according to the characteristics of the conveyed material (such as weight, corrosiveness, temperature, etc.); the drive device provides power for the conveyor belt through the combination of motor and reducer; the roller is divided into drive roller and redirecting roller, the former drives the conveyor belt to operate, and the latter changes the running direction of the conveyor belt; rollers are used to support the conveyor belt and materials to reduce running resistance; the tensioning device ensures that the conveyor belt has sufficient tension to prevent slipping.

Belt Conveyor has significant advantages. First, it has a strong conveying capacity, and can adjust the bandwidth and running speed according to demand to meet the transportation of materials of different scales; second, it has a long conveying distance, and can achieve ultra-long-distance continuous conveying by connecting multiple devices in series or using special designs; third, it has stable and reliable operation, low noise, low energy consumption, and low maintenance cost; in addition, its conveying line layout is flexible, and it can be transported horizontally, inclined or even vertically, and can be bent according to the site terrain.

In terms of application scenarios, Belt Conveyor has a wide range of uses. In the mining industry, it undertakes the mining and transportation of bulk materials such as ore and coal; at port terminals, it is used to load and unload bulk cargo to improve cargo turnover efficiency; in the food, chemical and other industries, it can also be used to transport granular, powdered and even finished goods to ensure the continuity of the production process. With the development of technology, Belt Conveyor is upgrading towards intelligence, large capacity and long distance, and will play an important role in more fields in the future.

Operating principle of Belt Conveyor

Belt Conveyor is widely used in many industries such as mining, ports, chemicals, and grain processing due to its efficient, continuous, and stable material conveying capabilities. Its working principle is based on friction and mechanical transmission, and it mainly realizes material conveying through the coordinated operation of core components such as drive devices, conveyor belts, rollers, and tensioning devices.

The drive device is the power source for the operation of the belt conveyor, and is usually composed of a motor, a reducer, and a coupling. After the motor is started, the power is transmitted to the reducer through the coupling. The reducer reduces the high speed of the motor and increases the torque, and finally transmits the power of the appropriate speed and torque to the drive roller. The surface of the drive roller fits tightly with the conveyor belt, and the friction between the two drives the conveyor belt to run.

As a key component of the belt conveyor, the conveyor belt is responsible for carrying and conveying materials. Common materials include rubber belts, plastic belts, etc. During operation, the conveyor belt wraps around the drive roller and the redirecting roller to form a closed ring structure. When the driving roller rotates under the drive of the driving device, the friction force causes the conveyor belt to move in a predetermined direction, and the materials placed on the conveyor belt are transported from the feed end to the discharge end along with the movement of the conveyor belt.

The roller plays the role of supporting the conveyor belt and materials in the belt conveyor, and is divided into upper rollers and lower rollers. The upper roller supports the load-bearing section of the conveyor belt to ensure that the conveyor belt maintains a stable shape when conveying materials; the lower roller supports the return section of the conveyor belt. The roller is generally composed of a roller body and a bearing, which can rotate flexibly, effectively reducing the friction resistance of the conveyor belt during operation and reducing energy loss.

The function of the tensioning device is to keep a certain tension on the conveyor belt, ensure that there is enough friction between the conveyor belt and the driving roller, and prevent the conveyor belt from slipping. Common tensioning methods include weight type, spiral type and hydraulic type. The weight type tensioning device applies tension to the conveyor belt by hanging a heavy object; the spiral type uses a screw to adjust the tension of the conveyor belt; the hydraulic tensioning device accurately controls the tension through the hydraulic system to meet the needs of different working conditions.

Belt conveyors achieve efficient and continuous material transportation through the close coordination of various components, friction and mechanical transmission, providing an important guarantee for the automation and efficiency of industrial production.

Advantages and features of Belt Conveyor

Belt conveyor is a machine that transports materials in a continuous manner. With its unique design and excellent performance, it occupies an important position in many industries such as mining, ports, chemicals, and grain, and has many significant characteristics and advantages.

From the perspective of structure and principle, belt conveyors are mainly composed of conveyor belts, rollers, rollers, drive devices and other components. The conveyor belt is both a component that carries materials and a traction component. The friction between the driving roller and the conveyor belt drives the conveyor belt to run and realize continuous transportation of materials. This structural design is simple and reliable, with stable operation and relatively convenient maintenance.

The belt conveyor has a strong conveying capacity and can adjust the width and running speed of the conveyor belt according to actual needs. The conveying volume per hour can range from a few tons to thousands of tons, which can meet the material transportation needs of different scales. Its conveying distance is also very impressive, ranging from a few meters to thousands of meters. It can even achieve ultra-long distance transportation through the relay of multiple devices, reducing the intermediate transfer links and improving transportation efficiency.

In terms of energy saving and environmental protection, compared with other transportation equipment, belt conveyors have less friction and lower energy consumption during operation; at the same time, the closed conveying design can effectively prevent materials from spilling and dusting during transportation, reduce pollution to the environment, and meet the requirements of green production. In addition, it has strong applicability and can convey materials in various forms such as powder, granular, and block, and can adapt to different conveying angles such as horizontal, inclined, and even vertical (special design).

In terms of automation and cost control, belt conveyors are easy to realize automatic control and can be linked with other production equipment to form an intelligent production and transportation system; and its structure is simple, parts are highly versatile, maintenance and replacement are convenient, equipment service life is long, and comprehensive operating costs are low. With these outstanding characteristics and advantages, belt conveyors have become one of the preferred equipment for material transportation in modern industrial production, and will continue to upgrade and optimize with technological development.

Technical Parameter Table of Belt Conveyor

| Specification / Model | B500 | B650 | B800 | B1000 |

|---|---|---|---|---|

| Belt Width | 500 mm | 650 mm | 800 mm | 1000 mm |

| Conveyor Length (customizable) | 5–30 m | 5–50 m | 5–80 m | 5–100 m |

| Belt Speed | 0.8–2.0 m/s | 0.8–2.0 m/s | 0.8–2.5 m/s | 0.8–2.5 m/s |

| Capacity | 60–120 t/h | 100–200 t/h | 200–400 t/h | 300–600 t/h |

| Motor Power | 3–7.5 kW | 4–11 kW | 5.5–18.5 kW | 7.5–22 kW |

| Frame Structure | Truss / Tube Steel | Truss / Tube Steel | Truss / Tube Steel | Truss / Tube Steel |

| Belt Type | EP Rubber Belt | EP Rubber Belt | EP Rubber Belt | EP Rubber Belt |

| Inclination Angle | ≤18° | ≤18° | ≤18° | ≤18° |

If you have any special requirements, we will customize according to your special needs.

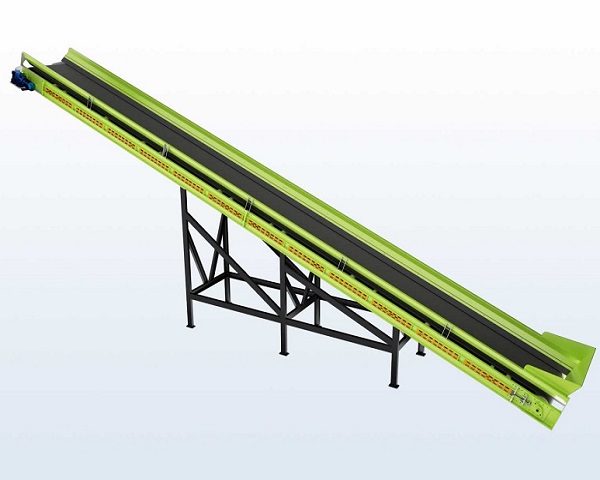

Product Picture Display of Belt Conveyor

FAQ about Belt Conveyor

What is the working principle of Belt Conveyor?

Belt Conveyor relies on the driving device to drive the active roller, and drives the conveyor belt to run with the help of the friction between the roller and the conveyor belt. The material is placed on the conveyor belt, and under the drive of the conveyor belt, it moves with the conveyor belt by friction and its own gravity, thus completing the material conveying process.

What types of Belt Conveyor are there?

According to the structure, it can be divided into horizontal belt conveyor, inclined belt conveyor, turning belt conveyor, etc.; according to the material of the conveyor belt, it can be divided into rubber belt conveyor, plastic belt conveyor, etc.; according to the driving mode, it can be divided into single roller drive and multi-roller drive. Different types are suitable for different working conditions and material conveying needs.

What are the advantages of Belt Conveyor?

Belt Conveyor has the advantages of long conveying distance, large conveying capacity, low energy consumption, stable operation, simple operation and convenient maintenance. It can realize continuous conveying, reduce the number of material loading and unloading, and improve production efficiency. At the same time, it can also be transported in various ways such as horizontal and inclined according to needs.

What should I pay attention to when using Belt Conveyor?

When using, ensure that the material is fed evenly to avoid local overload; regularly check the wear and tension of the conveyor belt to prevent the conveyor belt from deviating or breaking; keep all parts well lubricated; start and stop the equipment strictly in accordance with the operating procedures, and stop the machine for repair in time if abnormalities occur.

How to maintain the Belt Conveyor?

Regularly clean the material residue on the conveyor belt to prevent material accumulation from affecting operation; check whether the conveyor belt joints are firm and cracked; lubricate the rotating parts such as rollers and idlers; adjust the conveyor belt deviation; replace the severely worn parts in time to ensure the normal operation of the equipment.

How to solve the conveyor belt deviation of the Belt Conveyor?

First check whether the idlers are installed in parallel. If not, adjust the position of the idlers; check whether the rollers are sticky and clean the surface of the rollers; adjust the tensioning device to make the conveyor belt evenly stressed; you can also correct the conveyor belt deviation by adjusting the self-aligning idlers or installing anti-deviation devices.

What materials are suitable for conveying Belt Conveyors?

Belt Conveyor is suitable for conveying bulk materials such as powder, granular, small blocks, such as coal, ore, sand and gravel, grain, etc. It can also convey piece items. However, for materials with special properties such as strong corrosiveness, high temperature, flammable and explosive, conveyor belts with special materials and protective measures are required.

How to determine the conveying speed of Belt Conveyor?

The conveying speed needs to comprehensively consider factors such as material properties, conveying volume, conveyor belt width, and conveying distance. Generally speaking, the conveying speed of powdery materials is lower, and the speed of granular materials can be appropriately increased; when the conveying volume is large and the distance is long, a higher conveying speed can be selected, but it is necessary to ensure that the material is stable and does not spill during the conveying process.

How to calculate the driving power of Belt Conveyor?

The calculation of driving power involves parameters such as material weight, conveying length, conveying height, conveyor belt speed, and running resistance. It is usually calculated based on empirical formulas or with the help of professional software. At the same time, a certain safety factor must be considered to ensure that the drive device can meet the actual operation requirements.

What is the future development trend of Belt Conveyor?

In the future, belt conveyors will develop towards intelligence, large-scale, energy-saving and environmental protection. Intelligence is reflected in functions such as automatic monitoring and fault diagnosis; large-scale can meet the needs of large-scale material transportation; energy saving reduces energy consumption by optimizing structure and adopting efficient drive technology; environmental protection focuses on reducing dust leakage and noise pollution.