A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

Construction Waste Screening Solution Introduce

Zhongcheng Machinery designed a scientific and reasonable overall plan for the crushing and screening of construction waste for a construction waste treatment in the Philippines.

1. Crushing and processing

Crushing is the key link in the treatment of construction waste. According to the composition characteristics of construction waste, jaw crushers and impact crushers are mainly used. Jaw crushers are suitable for processing hard materials such as bricks and concrete. They crush materials through the pressure and swing of the plates, with good crushing effect and high quality of crushed materials. Impact crushers are used to process materials that jaw crushers cannot process again. They have strong crushing ability and can crush coarse materials in a short time.

2. Screening and processing

Screening is an important step to classify the crushed construction waste according to particle size and properties. Commonly used screening equipment includes circular vibrating screens, fixed screens and cyclone screens. The circular vibrating screen makes the material move along the free fall through the internal vibration of the equipment to achieve material classification; the fixed screen uses the natural flow of the material to classify, which is suitable for large particle materials; the cyclone screen has the characteristics of high precision and clear screening efficiency, which is suitable for the classification and screening of materials with a wide range of particle sizes.

3. Subsequent utilization

After crushing and screening, construction waste is recycled. The screened materials of different particle sizes can be used for road foundation filling, construction material recycling, etc. For example, some particles can be used in construction, roadbed, cement products and other fields. At the same time, recyclable materials such as steel bars and wood in construction waste are effectively recycled and reused during the crushing and disposal process, reducing the consumption of natural resources and the negative impact of construction activities on the environment.

This plan promotes the implementation of the construction waste crushing and screening treatment plan, and promotes the resource utilization and sustainable development of construction waste.

Advantages and features of Construction Waste Screening Solution

The advantages and characteristics of this construction waste crushing and screening solution are reflected in the crushing efficiency, screening efficiency, high screening purity, energy saving and environmental protection:

1. Revolutionary breakthrough in efficiency

a. Crushing efficiency upgrade

The three-stage crushing matrix of "jaw crusher + cone crusher + shaping crusher" is adopted to adapt to the complex composition of construction waste in the Philippines. The efficiency of the jaw crusher in coarse crushing of reinforced concrete is 85%, and the fine crushing capacity of the cone crusher is 400t/h, which is 60% higher than that of traditional equipment. The shaping crusher optimizes the aggregate particle shape, and the needle-like content is less than 5%, meeting the C30 concrete standard.

b. Leap in screening accuracy

The four-layer high-frequency vibrating screen realizes four-level sorting of 0-5/5-10/10-20/20+mm with an accuracy of 98%. Integrated air separation and magnetic separation system, the separation rate of light materials is 99.2%, and the metal recovery rate exceeds 99.5%. AI visual recognition assists sorting, and the impurity recognition accuracy is 0.1mm, ensuring the SS grade standard of recycled aggregate.

2. Breakthrough in environmental protection technology

Innovation in dust control

Dual system of pulse bag dust removal + water mist dust reduction, dust emission <30mg/m³ (Philippine environmental protection standard 150mg/m³). The diameter of specially designed water mist particles is <100μm, the coverage area is increased by 40%, and water saving is 35%. The closed working space is combined with negative pressure collection to prevent dust from escaping.

Optimization of noise control

The combination of fully enclosed soundproof cover + silencer reduces the noise in the working area to 75dB (city limit 85dB). The modular silencer structure absorbs low-frequency noise, and night operations meet the environmental protection requirements of residential areas.

Energy circulation system

Permanent magnet synchronous motor saves 28% energy compared with traditional motors, and intelligent frequency conversion control reduces no-load loss by 40%. The wastewater recycling rate reaches 90%, and the cooling water closed-loop system reduces fresh water consumption by 70%.

3. Improved comprehensive benefits

Double breakthrough in production capacity and quality: single-line processing capacity reaches 350t/h, recycled aggregate crushing value <12% (natural sand standard), and moisture content <0.5%. Data from a Manila project shows that processing 10,000 tons of construction waste can produce 150,000 recycled bricks and 22,000 cubic meters of road base materials.

This solution achieves a double breakthrough in efficiency and environmental protection through technological innovation, increasing the conversion value of construction waste by more than 10 times. The modular design supports rapid deployment and shortens the investment payback period to 3 years, providing a sustainable solution for the treatment of construction waste in the Philippines and helping to achieve the strategic goal of "zero waste city".

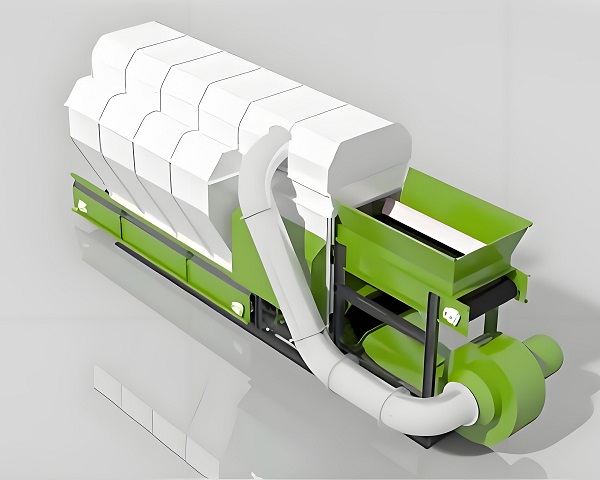

Main Machine

Customer Feedback

Customer evaluation of the Philippines construction waste crushing and screening solution

Philippine customers highly praised the solution, saying that it has completely changed the mode of construction waste treatment. The person in charge of a building materials company said: "The equipment crushing efficiency exceeded expectations, with a processing capacity of 350 tons per hour, and the needle-like content of recycled aggregate is less than 5%, which fully meets the needs of concrete production." Environmental performance has become a key plus point. Customers reported that dust emissions were controlled below 30mg/m³, far below the Philippine environmental protection standard, and the noise barrier made night operations no longer disturbing. The economic benefits are more recognized. Data from a project in Manila showed that the cost of concrete was reduced by 35% after the use of recycled aggregates, saving more than one million yuan per year. Customers especially praised the modular design and intelligent control system, the fast equipment transfer, the failure rate of less than 0.5%, and the 24-hour response of the after-sales service team. Many companies said: "This solution not only solves environmental problems, but also creates a new business chain with sustainable profits. It is a revolutionary breakthrough in the treatment of construction waste."