A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

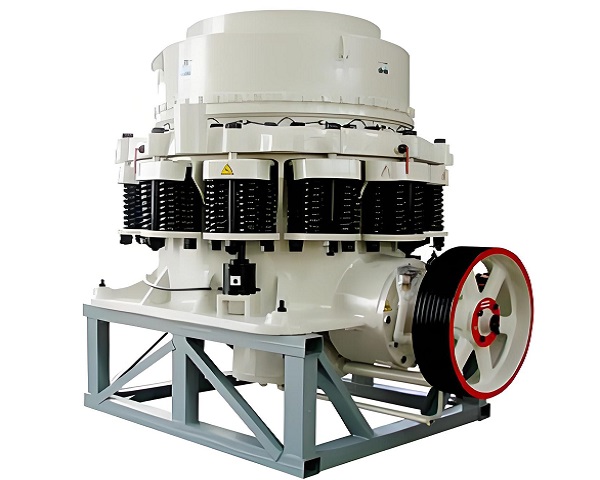

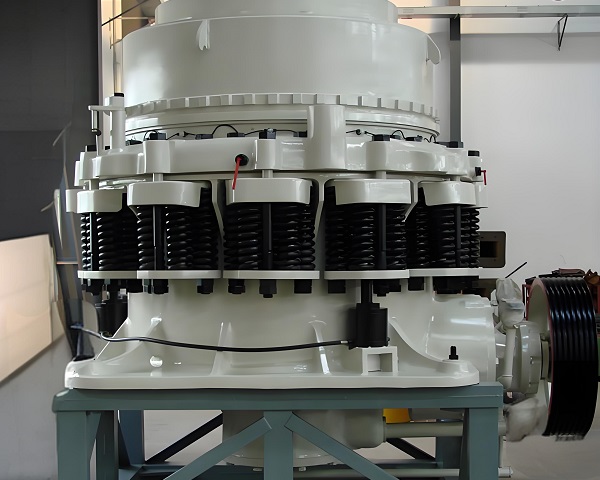

What is the Spring Cone Crusher

Spring cone crusher is a traditional crushing equipment widely used in fine crushing of medium-hard and above materials. It is mainly composed of core components such as frame, transmission device, eccentric sleeve, crushing cone, spring safety system, etc. Its working principle is to drive the horizontal shaft to rotate through the motor, and use the eccentric sleeve to drive the moving cone to do pendulum motion, so that the material is crushed by multiple forces such as extrusion, impact and bending in the crushing chamber. Due to its reliable structure, simple maintenance and low cost, this equipment still maintains an important position in mining, building materials, metallurgy and other fields.

Core structure and technical features

1. Spring overload protection mechanism: When unbreakable objects (such as iron blocks) enter the cavity or overload operation, the spring system automatically compresses, enlarges the discharge port to discharge foreign objects, avoids equipment damage, and significantly improves safety.

2. Layered crushing principle: The crushing chamber formed by the moving cone and the fixed cone is designed in a stepped shape. The material undergoes multiple extrusions and grinding in the cavity, and finally forms uniform cubic particles, which are suitable for high-grade aggregate production.

3. Wear-resistant parts configuration: The crushing wall and mortar wall made of high manganese steel or alloy steel can adapt to high-hardness materials (such as granite, basalt, iron ore, etc.), with long service life and easy replacement.

4. Limitations: The discharge port adjustment requires manual operation after stopping the machine, and the production efficiency and degree of automation are lower than those of modern hydraulic cone crushers, but the requirements for electricity and maintenance conditions are lower.

Typical application scenarios

- Sand and gravel aggregate processing: As a secondary or tertiary crushing equipment, the raw materials after jaw crushing (≤250mm) are further crushed into 5-60mm building aggregates.

- Ore dressing process: Finely crush gold, copper, iron and other ores before the ball mill to reduce the particle size entering the mill and improve the ore dressing efficiency.

- Building materials and chemicals: Process cement clinker, quartz stone, limestone and other materials to meet the particle size requirements of building materials production.

- Special working conditions: Suitable for small and medium-sized production lines with unstable power supply or limited budget, and it has become a reliable choice with its low failure rate.

Development Trends and Comparisons

With the popularity of hydraulic cone crushers and multi-cylinder cone crushers, spring cone crushers are gradually lagging behind in automation and energy efficiency, but their advantages of simple structure and low maintenance cost still make them occupy a place in specific markets (such as developing countries or remote mining areas). In the future, some manufacturers will extend their technology life cycle by improving materials (such as composite wear-resistant materials) or partial hydraulicization (such as hydraulic cavity cleaning).

Spring cone crushers have become the representative equipment of traditional crushing processes with high cost performance and strong adaptability. They are especially suitable for medium and low-capacity projects that do not require high automation but focus on stability. They are classic medium and fine crushing solutions in the mining and building materials industries.

Operating principle of Spring Cone Crusher

The spring cone crusher is a medium and fine crushing equipment based on the principle of laminated crushing. Its core working process is achieved through the synergy of mechanical transmission, eccentric motion and spring protection system. The following systematically explains its working principle from three aspects: structural linkage, crushing process and key mechanism.

1. Core structural linkage and power transmission

The equipment is driven by a motor, and the power is transmitted to the horizontal transmission shaft through the pulley. The transmission direction is changed through a pair of spiral bevel gears, driving the eccentric sleeve to rotate around the main shaft. The eccentric sleeve is embedded with a bronze bushing, forming an eccentric structure with the main shaft (the eccentric distance is usually 20-50mm). When the eccentric sleeve rotates, it forces the moving cone (crushing cone) to perform periodic pendulum motion with the main shaft as the fulcrum, forming a composite motion trajectory of "revolution around the main shaft + rotation". This movement causes the volume of the crushing chamber between the moving cone surface and the fixed cone (fixed cone) to change regularly, realizing continuous extrusion and release of materials.

2. Layered crushing process

After the material falls into the crushing chamber from the top feed port, it undergoes three stages of crushing:

- Coarse crushing area (feed port to middle): When the moving cone approaches the fixed cone, the large pieces of material are squeezed and broken for the first time;

- Medium crushing area (middle of the chamber): The material is squeezed multiple times during the swing of the moving cone, and is further refined due to the collision between particles;

- Parallel area (near the discharge port): The moving cone and the fixed cone are nearly parallel, forming a stable slit to ensure uniform discharge particle size (usually 5-60mm).

Since the moving cone completes a "squeeze-release" cycle every time it rotates, the material falls layer by layer under the action of gravity, and finally the particles that meet the particle size requirements are discharged from the bottom discharge port, and the particles that do not meet the standard continue to be retained and crushed.

3. The key role of the spring safety system

When the equipment is overloaded (such as iron blocks mixed in) or the discharge port is blocked, the crushing force increases sharply. At this time, the spring group (usually 6-12 groups) is compressed, pushing the support sleeve and the adjustment ring to lift up, instantly expanding the discharge port to discharge foreign matter. When the load returns to normal, the spring rebounds to reset the moving cone to avoid damage to the equipment. Although the response speed of this mechanism is not as fast as the hydraulic system, it has a simple structure and is maintenance-free, which is especially suitable for harsh working conditions.

4. Kinematic and mechanical characteristics

- Swing frequency: determined by the speed of the eccentric sleeve (usually 200-400r/min). The higher the speed, the higher the crushing efficiency, but the more severe the wear;

- Crushing force distribution: the linear speed of each point on the surface of the moving cone is different, the bottom stroke is large and the crushing force is strong, so the wear is concentrated on the lower part;

- Energy utilization: laminated crushing causes the material to be subjected to multi-directional stress in the cavity, which is more energy-efficient than single-point impact (saving 15-20% more electricity than jaw crusher).

5. Limitation Analysis

- Adjustment hysteresis: the discharge port needs to be shut down and the adjustment ring needs to be manually rotated, which cannot be adjusted in real time like a hydraulic cone crusher;

- Dynamic balance depends on the spring: spring fatigue after long-term use may cause the sensitivity of overload protection to decrease.

The spring cone crusher achieves progressive lamination crushing of materials through eccentric swing motion, and its spring safety mechanism ensures the reliability of the equipment at a low cost. Although the degree of automation is limited, its simple structure and convenient maintenance make it irreplaceable in small and medium-sized crushing lines.

Advantages and features of Spring Cone Crusher

As a traditional medium and fine crushing equipment, the spring cone crusher continues to play an important role in mining, building materials, metallurgy and other fields with its unique mechanical structure and reliable performance. The following is a systematic explanation from three dimensions: technical characteristics, performance advantages and applicability.

Core structural features

1. Spring overload protection system

- Multiple sets of high-strength spiral springs (usually 6-12 sets) are used as safety devices. When unbreakable objects enter or are overloaded, the spring is compressed to expand the discharge port instantly, and the foreign objects are automatically reset after being discharged without shutdown intervention.

- Compared with the hydraulic system, the structure is simple and there is no risk of oil leakage. It is suitable for harsh environments with large dust and large temperature differences.

2. Eccentric sleeve and oscillating motion

- The eccentric sleeve drives the moving cone to do oscillating motion to form a continuous extrusion-release laminated crushing, with high crushing efficiency and uniform particle size (cubic proportion ≥80%).

- The eccentric distance can be customized (20-50mm) to meet different production capacity requirements.

3. Modular wear-resistant design

- The crushing wall and the mortar wall are made of high manganese steel or alloy steel, fixed by bolts, and easy to replace (single replacement time ≤ 4 hours).

- The length of the parallel zone is adjustable to extend the service life of wear-resistant parts (usually 300-800 hours).

Core performance advantages

1. High reliability

- The mechanical structure is simple and the failure rate is low (the average number of failures per year is less than 2 times), which is particularly suitable for remote mining areas with unstable power supply.

- The spring system is maintenance-free, there is no aging problem of hydraulic components, and the comprehensive life of the equipment can reach more than 10 years.

2. Low operating cost

- The energy consumption is 15-20% lower than that of the jaw crusher, and the power consumption per ton of crushing is about 0.8-1.2kWh;

- The maintenance cost is only 40%-60% of that of the hydraulic cone crusher (annual maintenance cost < 5% of the equipment price).

3. Wide adaptability

- Can process various materials with compressive strength ≤350MPa, including hard rocks such as granite, iron ore, quartz stone, and renewable resources such as steel slag and construction waste;

- Wide range of discharging particle size (5-60mm), by replacing the eccentric sleeve or adjusting the parallel zone to meet different needs such as aggregates and ore dressing.

Comparison of advantages and applicable scenarios

1. Comparison of hydraulic cone crusher

- Advantages: 30%-50% lower purchase cost; low technical requirements for operators; no hydraulic system temperature rise problem (applicable to -30℃ to 50℃ environment).

- Disadvantages: The discharge port adjustment requires shutdown (taking 20-30 minutes), which is not suitable for flexible production lines with frequent adjustments.

2. Typical application scenarios

-Sand and gravel aggregate secondary crushing: as a secondary crushing equipment, it forms a low-cost production line with jaw crusher (50-300 tons per hour);

-Ore dressing pretreatment: provide ≤25mm in-grinding materials for ball mill to reduce grinding energy consumption;

-Special working conditions: small and medium-sized projects in areas with weak infrastructure such as Africa and Southeast Asia.

Technology development trend

1. Local improvement: Some manufacturers use hydraulic auxiliary adjustment (such as hydraulic top cylinder to quickly disassemble and install wear-resistant parts) to improve maintenance efficiency;

2. Material upgrade: composite wear-resistant materials (such as ceramic inlaid mortar wall) extend the service life to more than 1200 hours.

Spring cone crusher has "high reliability, low investment, and strong adaptability" as its core competitiveness. Although it has shortcomings in automation, its economy and durability make it still the preferred equipment in small and medium-sized capacity projects, harsh environments and budget-constrained scenarios.

Technical Parameter Table of Spring Cone Crusher

| Model | Crushing Cavity Type | Max Feed Size (mm) | Discharge Range (mm) | Capacity (t/h) | Motor Power (kW) | Main Shaft Speed (r/min) | Weight (kg) | Dimensions (mm) |

|---|---|---|---|---|---|---|---|---|

| PYB600 | Coarse | 65 | 12–25 | 12–25 | 30 | 356 | 5000 | 2234 × 1370 × 1675 |

| PYZ600 | Medium | 35 | 5–13 | 5–20 | 30 | 356 | 5500 | 2234 × 1370 × 1675 |

| PYD600 | Fine | 35 | 3–13 | 5–15 | 30 | 356 | 5500 | 2234 × 1370 × 1675 |

| PYB900 | Coarse | 115 | 15–50 | 50–90 | 55 | 333 | 11200 | 2692 × 1640 × 2350 |

| PYZ900 | Medium | 60 | 5–20 | 20–65 | 55 | 333 | 11300 | 2692 × 1640 × 2350 |

| PYD900 | Fine | 50 | 3–13 | 15–50 | 55 | 333 | 11300 | 2692 × 1640 × 2350 |

| PYB1200 | Coarse | 145 | 20–50 | 110–200 | 110 | 300 | 24700 | 2790 × 1878 × 2844 |

| PYZ1200 | Medium | 100 | 8–25 | 42–135 | 110 | 300 | 25000 | 2790 × 1878 × 2844 |

| PYD1200 | Fine | 50 | 3–15 | 18–105 | 110 | 300 | 25000 | 2790 × 1878 × 2844 |

| PYB1750 | Coarse | 215 | 25–60 | 280–480 | 160 | 245 | 50300 | 3910 × 2894 × 3809 |

| PYZ1750 | Medium | 185 | 10–30 | 115–320 | 160 | 245 | 50500 | 3910 × 2894 × 3809 |

| PYD1750 | Fine | 85 | 5–15 | 75–230 | 160 | 245 | 50500 | 3910 × 2894 × 3809 |

| PYB2200 | Coarse | 300 | 30–60 | 420–700 | 280–260 | 220 | 80000 | 4622 × 3302 × 4470 |

| PYZ2200 | Medium | 230 | 10–30 | 200–580 | 280–260 | 220 | 80500 | 4622 × 3302 × 4470 |

| PYD2200 | Fine | 100 | 5–15 | 120–340 | 280–260 | 220 | 80500 | 4622 × 3302 × 4470 |

If you have any special requirements, we will customize according to your special needs.

Product Picture Display of Spring Cone Crusher

FAQ about Spring Cone Crusher

>1. What is the working principle of the spring cone crusher?

The spring cone crusher drives the eccentric sleeve to rotate through the motor, driving the moving cone to do the pendulum motion, so that the material is squeezed, impacted and ground in the crushing chamber. The spring system provides overload protection. When encountering unbreakable objects or overload, the spring is compressed to expand the discharge port, and automatically reset after the foreign matter is discharged to ensure the safe operation of the equipment.

>2. What materials are suitable for the spring cone crusher to crush?

This equipment is suitable for medium and high hardness materials (compressive strength ≤350MPa), such as natural ores such as granite, basalt, iron ore, and quartz stone. It can also be used to crush recycled resources such as steel slag and construction waste. It is widely used in sand and gravel aggregates and mineral processing industries.

>3. What is the difference between a spring cone crusher and a hydraulic cone crusher?

The spring cone crusher uses a mechanical spring overload protection, with a simple structure and low cost, but the discharge port needs to be adjusted manually; the hydraulic cone crusher uses a hydraulic system with a high degree of automation and can adjust the discharge port in real time, but the purchase and maintenance costs are high. Spring cone crusher is more suitable for occasions with limited budget or harsh environment.

>4. How to adjust the discharge particle size of spring cone crusher?

The spacing between the moving cone and the fixed cone is changed by rotating the adjustment ring to control the discharge particle size (usually 5-60mm). The machine needs to be stopped for adjustment, which takes about 20-30 minutes. It cannot be adjusted in real time like hydraulic cone crusher.

>5. What is the life of wear parts of spring cone crusher?

Wear parts (crushing wall, mortar wall) are usually made of high manganese steel or alloy steel, with a life of about 300-800 hours, depending on the hardness of the material and working conditions. Optimizing the length of the parallel zone and using composite wear-resistant materials can extend the service life to more than 1200 hours.

>6. What is the capacity range of spring cone crusher?

Depending on the model, the capacity is usually between 50-300 tons/hour. The output can be optimized by adjusting the eccentric sleeve speed, discharge port size and motor power. It is suitable for small and medium-sized crushing production lines.

>7. Is the maintenance cost of spring cone crusher high?

The maintenance cost is low, and the average annual maintenance cost usually does not exceed 5% of the equipment price. The spring system does not require special maintenance, and the main replacement of wearing parts (such as wear-resistant parts, bearings, etc.) is suitable for projects with limited budgets.

>8. What are the common faults of spring cone crusher? How to solve them?

Common faults include spring failure, bearing overheating, crushing chamber blockage, etc. The solution includes regular inspection of spring elasticity, ensuring the normal operation of the lubrication system, and avoiding overload operation. The failure rate is low, and the average number of failures per year is usually less than 2 times.

>9. How does the spring cone crusher perform in terms of environmental protection?

The noise and dust of the equipment are controllable during operation, which meets general environmental protection requirements. It can be further optimized by adding dust covers and noise reduction measures, but compared with hydraulic cone crushers, its automatic adjustment ability is weaker, which may affect refined production.

>10. What is the future development trend of spring cone crusher?

Future improvement directions include local hydraulicization (such as hydraulic assisted adjustment), upgrades to wear-resistant materials (such as ceramic composite liners), and intelligent monitoring (such as adding sensors to monitor spring status in real time) to enhance its automation level and competitiveness.