A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

What is the PY Cone Crusher

PY cone crusher is a classic representative of traditional medium and fine crushing equipment. With its reliable spring mechanical structure and mature crushing process, it continues to play an important role in the field of mining crushing. This article will comprehensively analyze the technical characteristics of PY series cone crusher from the dimensions of equipment structure, working principle, performance characteristics, etc., and objectively evaluate its applicable scenarios and economic benefits in modern crushing production lines based on actual application data, providing professional reference for equipment selection.

1. Equipment Overview

PY cone crusher is a traditional medium and fine crushing equipment using a mechanical spring overload protection system. It consists of core components such as a frame, a transmission system, and an eccentric sleeve assembly. This model has been verified in the market for more than half a century. It plays a key role in the secondary crushing process chain. It has become a classic choice for small and medium-sized projects with its simple structure and convenient maintenance.

2. Core Features

The equipment uses 6-12 sets of high-strength spiral springs to achieve overload protection, equipped with a helical gear transmission system (efficiency ≥ 95%) and an optimized crushing cavity. The unique "coarse crushing zone-parallel zone" two-stage design increases the crushing ratio to 1:8. By replacing the three liner plates PYB/PYZ/PYD, it can adapt to different particle size requirements.

3. Performance parameters

The standard model has a processing capacity of 15-1050t/h, a discharge particle size of 3-60mm (need to stop for adjustment), and is suitable for materials with a compressive strength of ≤350MPa. A typical example is the PYB1200 model, which has an output of 300 tons per hour, a power consumption of 0.8-1.2kWh per ton of crushing, and a spring life of up to 50,000 compression cycles.

4. Application areas

Mainly used in: ① Secondary crushing of sand and gravel aggregates (finished product 5-31.5mm); ② Pre-grinding crushing of metal ore (feed ≤15mm); ③ Processing of building materials such as cement clinker. In a granite project, the PYB1650 model achieved an output of 600 tons per hour, and the cubic content of the finished product was ≥90%.

5. Economical maintenance

It takes 4-6 hours to replace the liner, and the annual maintenance cost is about 4-7% of the equipment value. The purchase cost is only 40-60% of the hydraulic cone crusher. Taking PYB900 as an example, the electricity cost per ton of crushing is 0.48-0.72 yuan, which has significant advantages in projects with limited budgets.

6. Technological evolution

The new PYH series adds a hydraulic cavity cleaning function, which shortens the maintenance time by 60%; the life of the boron-titanium composite liner in the test is increased by 50%; the intelligent monitoring system makes the fault recognition rate reach 85%, and continuously improves the competitiveness of traditional equipment.

7. Selection suggestions

For projects with an output of ≤500 tons per hour, the preferred choice is: PYB standard type for aggregate production, PYD short head type for ore dressing and fine crushing, and PYZ for medium-sized needs. It is particularly suitable for working conditions with unstable power or limited investment.

8. Market positioning

With high reliability and low maintenance threshold, it has a market share of more than 30% in developing countries. After technological transformation, it is expected to continue to play an irreplaceable role in specific scenarios for a long time.

PY cone crusher still has irreplaceable value in small and medium-sized crushing projects due to its simple structure, convenient maintenance and high cost-effectiveness. Although its adjustment flexibility is not as good as that of hydraulic models, its excellent reliability and low operating costs make it a unique advantage in projects with limited power conditions or tight investment budgets. With the introduction of technologies such as local hydraulicization and intelligent monitoring, PY series equipment is gaining new vitality and is expected to remain competitive in specific market areas in the long term.

Operating principle of PY Cone Crusher

Core crushing mechanism

PY cone crusher adopts the working principle of combining "laminated crushing" and "selective crushing". When the material enters the crushing chamber composed of the moving cone and the fixed cone, it is first subjected to the initial impact of the moving cone in the feeding area; with the periodic swing of the moving cone, the material undergoes multiple extrusions and grinding in the crushing area; and finally the particle size shaping is completed in the parallel area. This progressive crushing process subjects the material to compound stress in three-dimensional space, and the energy utilization rate is increased by 25-30% compared with single-point impact crushing, and the over-crushing phenomenon can be effectively controlled.

Power transmission system

1. Motor drive:

The motor drives the horizontal drive shaft to rotate through a V-belt (transmission ratio 1:1.5~1:2.2), and is supported by heavy-duty spherical roller bearings to ensure transmission stability. The latest model is equipped with frequency conversion control, and the speed can be adjusted within the range of 280-400rpm.

2. Gear transmission:

The spiral bevel gear pair (AGMA 10 precision) converts horizontal rotation into vertical rotation, the gear module is 12-20mm, and the dual system of splash lubrication and forced lubrication is adopted, and the transmission efficiency is ≥93%.

3. Eccentric mechanism:

The eccentric sleeve is embedded with a zinc alloy bushing, with a standard eccentricity of 35-50mm (customizable ±5mm), which converts the rotational motion into a compound swing of the moving cone, with a swing frequency of 180-400 times/minute.

Working principle of spring system

1. Overload protection:

12 groups of spiral springs (elastic coefficient 90-110N/mm) constitute a safety device. When the crushing force exceeds the set value (usually 120% of the rated value), the spring compression causes the support ring to lift, and the discharge port is instantly expanded by 8-15mm to release foreign matter, with a response time of 0.3-0.5 seconds.

2. Reset mechanism:

After the overload is released, the spring restoring force automatically resets the moving cone, with a reset accuracy of ±2mm. The spring preload can be adjusted by adjusting the nut (adjustment range ±10%).

Crushing chamber dynamics

1. Motion trajectory:

The axis of the moving cone forms an angle of 2°-3° with the center line of the machine. Its motion trajectory is a spatial involute, forming a constant crushing zone in the parallel zone to ensure the uniformity of the discharge particle size (coefficient of variation ≤15%).

2. Energy transfer:

The crushing force is directly transmitted to the frame through the main shaft, and the energy loss is <8%. The specially designed counterweight can balance more than 60% of the inertial force, and the vibration value of the equipment is controlled below 3.2mm/s.

Particle size control

1. Adjustment method:

The discharge port is mechanically adjusted by rotating the adjustment ring (range of 3-60mm). It needs to be operated with a special wrench after stopping the machine. A single adjustment takes 15-30 minutes. The latest improved version has added a hydraulic auxiliary adjustment device.

2. Particle size distribution:

The typical discharge curve shows that 80% of the particles are concentrated within the range of ±20% of the set value. In the PYB standard product, the -5mm content can be controlled at ≤15%.

Performance optimization

1. Cavity improvement:

The third-generation crushing chamber increases the parallel zone length by 20%, improves the liner wear uniformity by 40%, and extends the service life to 400-800 hours.

2. Speed adjustment:

The frequency converter matches the spindle speed with the feed rate. When processing sticky materials, the speed can be reduced by 10-15% to prevent cavity blockage.

Adaptation to special working conditions

1. Wet materials:

Add a liner heating device (optional) to process sticky materials with a moisture content of ≤7% to prevent material adhesion.

2. Superhard materials:

When using Cr26 high chromium cast iron liner, materials such as basalt with a compressive strength of ≤380MPa can be crushed, but the processing volume needs to be reduced by 20% accordingly.

Technological Evolution

The latest PYH improved model has achieved:

- Hydraulic assisted cavity cleaning (time shortened to 5 minutes)

- Online wear monitoring (RFID chip implanted in liner)

- Intelligent lubrication system (oil consumption reduced by 20%)

This working principle enables the PY cone crusher to maintain unique advantages in reliability (MTBF ≥ 2000 hours) and economy (the cost per ton of crushing is 30% lower than that of the hydraulic type), especially suitable for mining projects in areas with imperfect infrastructure. With the local intelligent transformation, this model is gradually adapting to the technical requirements of modern crushing production lines.

Advantages and features of PY Cone Crusher

PY cone crusher is a classic spring cone crushing equipment, which is widely used in medium and fine crushing operations in mining, metallurgy, building materials, chemical industry and other industries. It occupies an important position in traditional crushing equipment with its mature structure, stable performance and strong applicability. The following systematically summarizes its main features and advantages from the aspects of structural principle, performance characteristics and application advantages:

1. Mature structure and easy maintenance

PY cone crusher adopts spring insurance system as overload protection device, which has the characteristics of simple structure and high reliability. When the equipment enters non-crushed objects, the spring system can automatically release the crushing cavity to avoid equipment damage and ensure production continuity. The overall mechanical structure is compact and reasonable, and all parts can be maintained and disassembled from the top or side, reducing maintenance time and downtime costs. At the same time, its lubrication system and hydraulic cavity cleaning mechanism (some models) further improve the convenience of operation and maintenance safety.

2. High crushing efficiency and excellent finished product particle shape

The equipment adopts an optimized crushing cavity type and a reasonable combination of dynamic cone speed to achieve a larger throughput and higher crushing efficiency. The PY type cone crusher has a large crushing ratio and strong crushing capacity. It can achieve efficient crushing of medium and high hardness materials (such as granite, basalt, iron ore, etc.). Its finished product particle shape is cubic and has a low needle-like content. It is particularly suitable for engineering projects with high requirements for aggregate particle shape, such as highway and hydropower dam construction.

3. Strong adaptability and wide application

The PY series crusher provides a variety of chamber types (such as PYB standard type, PYZ medium type, PYD short head type), which can flexibly adapt to the working conditions of different particle sizes and discharge requirements. The standard type is mainly used for medium crushing operations, while the medium and short head types are used for fine and ultra-fine crushing operations, enabling the equipment to achieve multi-stage crushing in one project and improve the overall efficiency of the system. In addition, the equipment can also be flexibly combined with other crushing and screening equipment to form a closed or open circuit system, suitable for fixed and mobile production lines.

4. High cost performance and low operating cost

Compared with multi-cylinder hydraulic cone crusher and single-cylinder cone crusher, PY cone crusher has more advantages in equipment purchase cost, parts replacement cost and maintenance cost. Its spare parts are highly versatile and widely available in the market, and the later operation and maintenance costs are low, which is suitable for small and medium-sized enterprises or projects with limited budgets. At the same time, its energy consumption is low and the lubrication system is stable, which effectively reduces the energy consumption cost per ton of material.

5. Reliable process and stable quality

PY series cone crushers have been widely used worldwide for many years. The equipment structure has been repeatedly verified and continuously optimized, and has extremely high reliability. Key components such as moving cone, eccentric sleeve, main shaft, etc. are made of high-quality alloy steel, and are precision machined and heat treated to ensure the long-term stable operation of the equipment under high load and high impact environment.

6. Good environmental performance

Although the PY series is a traditional mechanical crushing equipment, it has stable operation, low vibration and low noise, which is convenient for closed operation or used in conjunction with dust removal equipment, which helps to reduce on-site dust and noise pollution and meets the requirements of modern industrial environmental protection.

As a crushing equipment that has been tested by the market for a long time, PY cone crusher has long served many industries and engineering projects around the world with its significant advantages such as reliable structure, easy maintenance, wide application range and high economy. Although its intelligence and automation level is slightly lower than that of new hydraulic cone crushers, it still has irreplaceable value in occasions with low to medium investment and high stability requirements. For users who pursue efficient and reliable crushing solutions, PY cone crusher is still a trustworthy choice.

Technical Parameter Table of PY Cone Crusher

| Model | Cone Diameter (mm) | Max Feed Size (mm) | Discharge Opening Range (mm) | Capacity (t/h) | Motor Power (kW) | Machine Weight (t) |

|---|---|---|---|---|---|---|

| PYB600 | 600 | 65 | 12–25 | 12–25 | 30 | 5.0 |

| PYB900 | 900 | 115 | 15–50 | 50–90 | 55 | 11.2 |

| PYB1200 | 1200 | 145 | 20–50 | 110–200 | 110 | 24.7 |

| PYB1750 | 1750 | 215 | 25–60 | 280–480 | 160 | 50.3 |

| PYB2200 | 2200 | 300 | 30–60 | 500–1000 | 280–300 | 80.0 |

If you have any special requirements, we will customize according to your special needs.

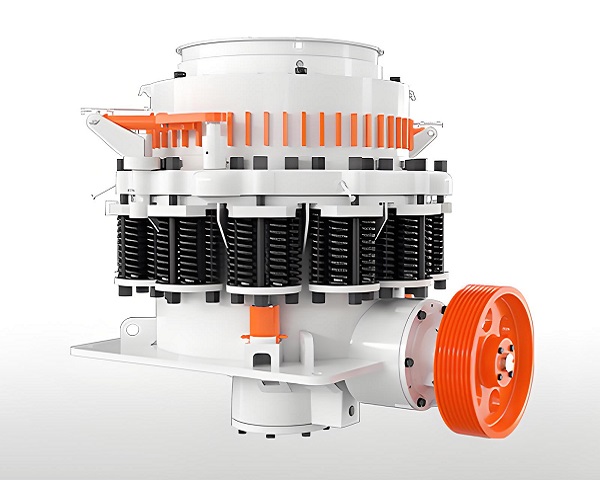

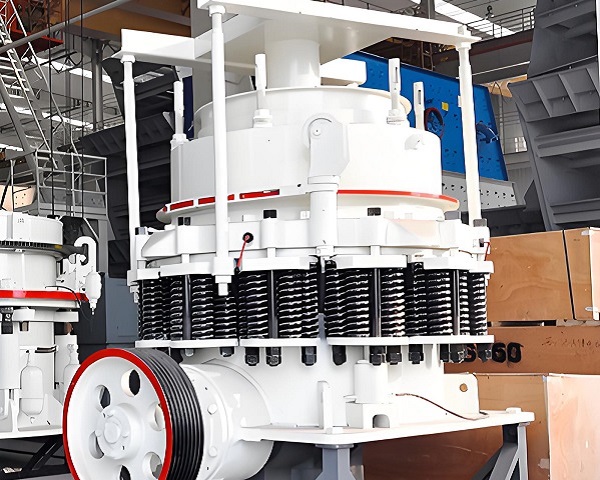

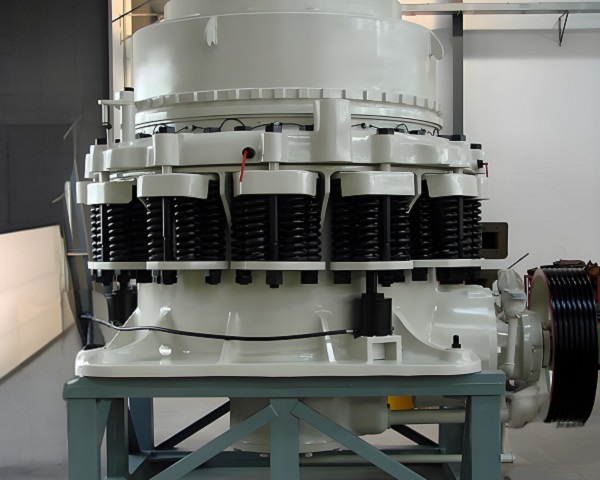

Product Picture Display of PY Cone Crusher

FAQ about PY Cone Crusher

>1. What materials are suitable for PY cone crusher?

PY cone crusher is suitable for various ores and rocks with medium and above hardness, such as basalt, granite, iron ore, limestone, copper ore, etc. It is widely used in mining, metallurgy, construction, water conservancy and chemical industries, especially suitable for medium and fine crushing operations with high requirements for particle shape and particle size control.

>2. What types of PY crushers are there? How to distinguish?

PY cone crusher is mainly divided into three types: PYB (standard type, for medium crushing), PYZ (medium type, for fine crushing) and PYD (short head type, for ultra-fine crushing). The main difference between them is the different structure and cone angle of the crushing chamber, resulting in different feed and discharge particle size ranges. Users can choose the appropriate model according to the material properties and particle size requirements.

>3. What is the working principle?

The PY cone crusher uses a spring structure as an overload protection system. Its working principle is to drive the eccentric sleeve to rotate through the motor, thereby pushing the moving cone to do a pendulum motion around the fixed cone, forming crushing effects such as extrusion, splitting and bending between the moving cone and the fixed cone, so that the material is continuously crushed and discharged from the bottom.

>4. What is the function of the spring safety device?

The spring safety device is the core protection mechanism of the PY crusher. When the equipment encounters iron blocks or overload conditions, it can automatically expand the cavity gap to allow foreign matter to pass through without damaging the main machine. After the foreign matter is discharged, the spring returns to its original state and the equipment continues to operate, thereby effectively preventing accidents and protecting the main shaft and bearing system.

>5. How to adjust the discharge particle size?

The discharge particle size of the PY cone crusher can be achieved by adjusting the gap between the moving cone and the fixed cone. Usually, the size of the discharge port is changed by rotating the adjustment ring or replacing lining plates of different specifications. The equipment must be kept in a stopped state during the adjustment process to avoid safety risks caused by misoperation during operation.

>6. Compared with hydraulic cone crusher, what are the advantages and disadvantages of PY type crusher?

Compared with hydraulic cone crusher, PY type cone crusher has simpler structure, easier maintenance and lower purchase cost, which is suitable for scenes with low requirements for crushing efficiency and automation. However, it lacks intelligent functions such as hydraulic adjustment and cavity cleaning, has slightly lower processing efficiency, and relies on manual operation, so it is slightly insufficient in high-capacity and automated occasions.

>7. How to perform daily maintenance?

Daily maintenance includes regular inspection of lubricating oil quality and oil level, cleaning or replacement of filter element, inspection of wear of moving cone and fixed cone lining, and ensuring that springs are intact and tension is appropriate. In addition, it is necessary to check whether the motor, bearings and transmission parts are running smoothly, so as to achieve "frequent inspection, early detection and quick processing".

>8. What are the common faults in use?

Common faults include: blockage of crushing chamber, uneven particle size of discharge, increased vibration of equipment, spring failure, lubrication system failure, etc. Most problems can be effectively prevented through standardized operation, timely cleaning of materials, regular maintenance and correct installation of components. If an abnormality occurs, the machine should be stopped immediately for investigation.

>9. How to improve its crushing efficiency?

The efficiency of PY cone crusher can be improved from the following aspects: reasonable selection of feed particle size, uniform feeding, regular replacement of wear parts, maintaining appropriate discharge port opening, using appropriate models and cavity types, and maintaining good lubrication and cooling of the equipment, thereby reducing energy consumption, improving production capacity and stability.

>10. Is this equipment suitable for mobile crushing station?

Although PY cone crusher is mostly used in fixed crushing production lines, it has a compact structure and moderate weight. It can also be combined with vibrating screens, belt conveyors, etc. to form semi-mobile or tire-type crushing stations, which are suitable for engineering projects with stable sites and infrequent changes. Compared with modern hydraulic cone crushers, its mobile integration is slightly lower, but its economy is higher.

If you need to make the above content into a brochure, web Q&A or interactive display, I can continue to assist in the design. Do you need further formatting or export?