A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

What is the Multi-cylinder Cone Crusher

As the core equipment of modern crushing production line, multi-cylinder hydraulic cone crusher adopts the innovative design of 6-8 groups of hydraulic cylinders working together, and realizes precise crushing force control and intelligent operation through hydraulic system. The equipment is comprehensively upgraded on the basis of traditional spring cone crusher, and consists of key components such as heavy-duty frame, transmission assembly, eccentric sleeve assembly, etc. The modular design is convenient for transportation and maintenance.

The core technology of the equipment is reflected in three aspects: the working pressure of the distributed hydraulic system reaches 6-14MPa, and the adjustment accuracy is ±0.5mm; the intelligent control system can monitor 16 operating parameters and support remote monitoring; the optimized laminated crushing cavity type makes the finished product cube content exceed 92%. These characteristics ensure that the equipment performs excellently in crushing efficiency and operating stability.

In terms of performance parameters, the equipment has a processing capacity of 100-1500 tons/hour, up to 2000 tons; the discharge particle size is continuously adjustable from 3-50mm; it is suitable for all kinds of ores with a compressive strength of ≤400MPa; the power consumption per ton of crushing is 0.6-1.0kWh; the life of the ultra-high manganese steel lining is 500-1500 hours, and the comprehensive performance leads the industry.

It has shown significant advantages in the application field: it can provide ball mills with ideal feed of ≤25mm in large-scale mine dressing; the production of high-end sand and gravel aggregates ensures a product qualification rate of more than 98%; the continuous operation rate of special building materials processing cement clinker and other super-hard materials is 95%, meeting diversified production needs.

The equipment maintenance is convenient: hydraulic assisted disassembly and assembly shortens the liner replacement time to within 4 hours; the annual maintenance cost accounts for only 4-6% of the equipment value. Taking the 800-ton production line as an example, the annual electricity bill is saved by about 500,000 yuan, the consumption of wear-resistant parts is reduced by 25%, and the economic benefits are significant.

Technological development shows three major trends: the industrial Internet platform realizes predictive maintenance; the noise of the new generation of models is controlled below 72dB; the nano-composite lining is expected to extend the service life to 2000 hours. These innovations will continue to improve equipment performance and market competitiveness.

Multi-cylinder hydraulic cone crusher has become the first choice for large-scale crushing production lines due to its advantages such as balanced crushing force, stable operation and high degree of intelligence. Although the initial investment is high, its excellent performance and long-term economy dominate the field of high-end crushing, and future development will be more intelligent, efficient and environmentally friendly.

Operating principle of Multi-cylinder Cone Crusher

The multi-cylinder hydraulic cone crusher adopts the principle of laminated crushing and achieves efficient crushing through the composite swinging motion of the moving cone. The material undergoes three stages of coarse crushing, medium crushing and fine crushing in the crushing chamber. The moving cone completes 180-360 crushing cycles per minute, making the finished product particle size uniform and the crushing efficiency increased by more than 35%.

The equipment adopts motor direct drive with high-precision spiral bevel gear transmission, and frequency conversion control realizes 180-360rpm stepless speed regulation. The eccentric sleeve assembly is equipped with a bimetallic bushing, and the 30-60mm adjustable eccentric distance is driven by a hydraulic motor to ensure motion accuracy and stability.

The innovative multi-cylinder hydraulic system is the core, with 6-8 groups of hydraulic cylinders (6-14MPa) distributedly arranged to achieve balanced distribution of crushing force. The system has the ability to adjust the discharge port with an accuracy of ±0.5mm, the overload protection response time is only 0.08 seconds, and the protection sensitivity is 15 times that of traditional equipment.

In terms of kinematic characteristics, the dynamic cone adopts a logarithmic spiral motion trajectory with an inclination of 2.5°-3.5°, and cooperates with a hydraulic accumulator and a mechanical counterweight to control the vibration value below 1.8mm/s. The energy transfer efficiency is as high as 97%, which is 12% higher than that of the single-cylinder model.

The intelligent control system monitors 16 parameters in real time (sampling frequency 200Hz) and has an adaptive adjustment function. The PLC can automatically optimize the working conditions according to the material characteristics, and the three-level protection system ensures the safety of the equipment. It takes only 0.5 seconds from warning to shutdown.

Technical innovation highlights include: multi-cylinder pressure balancing technology (pressure deviation within ±5%), intelligent lubrication system (fuel consumption reduced by 25%) and dynamic compensation device. These designs improve the running stability of the equipment by 30% and the lubrication efficiency by 40%.

With its efficient crushing capacity and intelligent characteristics, the equipment is particularly suitable for large-scale high-load operation scenarios. With the development of the industrial Internet, the new generation of equipment is evolving towards digital twins and cloud-based collaborative control, and continuously improving performance.

Advantages and features of Multi-cylinder Cone Crusher

As an advanced equipment in modern crushing technology, multi-cylinder hydraulic cone crusher integrates many cutting-edge technologies such as mechanical design, hydraulic transmission and intelligent control. This article systematically explains the technical innovations of the equipment in terms of structural design, working principle, performance advantages, etc., focuses on analyzing the technical characteristics of core components such as multi-cylinder hydraulic system and intelligent control module, and comprehensively evaluates its application value in large-scale mines and sand and gravel aggregates, etc., to provide comprehensive technical reference for industry users.

1. Multi-cylinder hydraulic system design: 6-8 groups of hydraulic cylinders are distributed, the working pressure is adjustable from 6-14MPa, and the pressure is automatically balanced through the hydraulic cross circuit (within ±5% deviation) to ensure uniform distribution of crushing force. Integrated discharge port adjustment, overload protection and cavity clearing functions, adjustment time <20 seconds, accuracy ±0.5mm, and running stability is improved by more than 30% compared with single-cylinder models.

2. Heavy-duty structure optimization: The high-strength cast steel frame has a design life of 10 years, and the modular transmission assembly shortens the component replacement time by 40%. The bidirectional labyrinth seal structure effectively prevents dust, extends the bearing life by 50%, and is suitable for wet materials with a mud content of ≤8%, meeting the requirements of harsh working conditions.

3. Efficient crushing performance: The asymmetric crushing chamber is combined with a precise moving cone motion trajectory (180-360 times/minute), achieving a finished product cube ratio of ≥92%, a needle-like content of <3%, and a production capacity increase of 25-40% compared with traditional equipment. The variable frequency speed regulation technology makes the power consumption per ton of crushing only 0.6-1.0kWh, and the annual power saving of an 800-ton production line per hour reaches 640,000 degrees.

4. Intelligent control system: The industrial-grade PLC monitors 16 parameters in real time (sampling frequency 200Hz), and has adaptive adjustment and remote operation and maintenance functions. The intelligent lubrication system saves 25% of fuel, and predictive maintenance can warn of faults 48 hours in advance, with a diagnostic accuracy of ≥98%, greatly reducing the risk of unexpected downtime.

5. Significant economic benefits: The life of the ultra-high manganese steel liner is 500-1500 hours, and the annual maintenance cost is only 4-6% of the equipment value. The initial investment can be recovered through energy saving and increased production in 2.5-3 years, and the return rate of the whole life cycle is increased by 35%, with a design life of 15 years.

6. Environmental and safety features: The triple noise reduction design makes the noise ≤72dB, and the fully enclosed structure with negative pressure dust removal achieves dust emission ≤15mg/m³. The dynamic balance technology controls the vibration value below 1.8mm/s, which is 50% higher than the industry standard, ensuring long-term stable operation.

7. Technological innovation breakthrough: The nano-composite liner (WC particle enhancement) in the test is expected to have a life of more than 2000 hours. The remote operation and maintenance platform provides health assessment and energy efficiency optimization, and the expert team responds quickly within 2 hours, supporting customized cavity and hydraulic parameter adjustment services.

8. Industry application positioning: As the core equipment of a large-scale crushing production line, it is particularly suitable for high-end sand and gravel aggregates and mining projects with an output of more than 500 tons per hour. It represents the highest level of current cone crushing technology and has irreplaceable advantages in product quality and operational benefits.

The multi-cylinder hydraulic cone crusher has shown significant advantages in crushing efficiency, operation stability and intelligence due to its innovative multi-cylinder hydraulic system, efficient laminated crushing principle and advanced intelligent control technology. The equipment not only achieves a high-cubic content finished product output of more than 92%, but also significantly reduces production costs through energy-saving design and intelligent operation and maintenance. Its modular structure, environmental protection characteristics and customized services make it an ideal choice for large-scale crushing production lines, representing the highest level of current cone crushing technology and providing reliable technical support for the high-quality development of the industry.

Technical Parameter Table of Multi-cylinder Cone Crusher

| Model | Cone Diameter (mm) | Max Feed Size (mm) | Discharge Opening Range (mm) | Capacity (t/h) | Motor Power (kW) | Weight (t) |

|---|---|---|---|---|---|---|

| HP100 | 750 | 80 | 6–25 | 70–120 | 90 | 6.5 |

| HP200 | 950 | 120 | 6–38 | 120–250 | 132 | 10.4 |

| HP300 | 1160 | 150 | 10–45 | 180–440 | 220 | 18.0 |

| HP400 | 1300 | 180 | 10–51 | 250–630 | 315 | 23.2 |

| HP500 | 1500 | 220 | 10–58 | 300–790 | 400 | 29.5 |

| HP800 | 1600 | 275 | 13–70 | 500–1200 | 630 | 55.0 |

If you have any special requirements, we will customize according to your special needs.

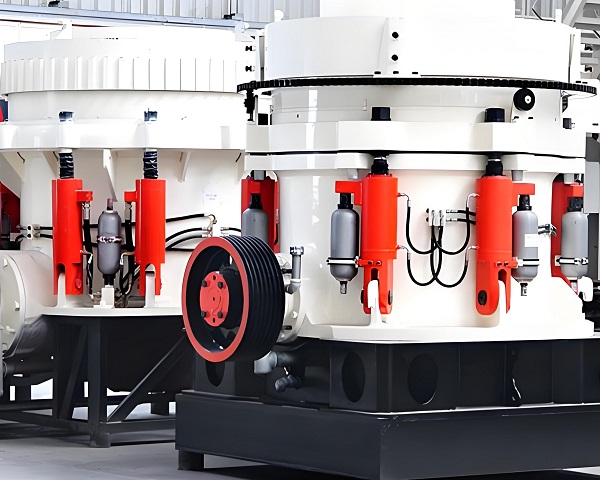

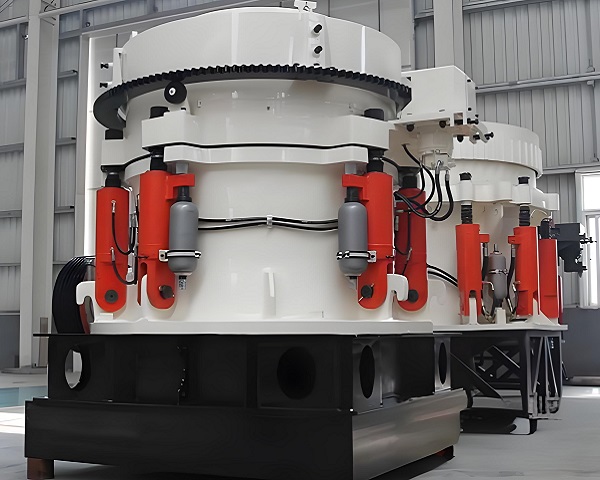

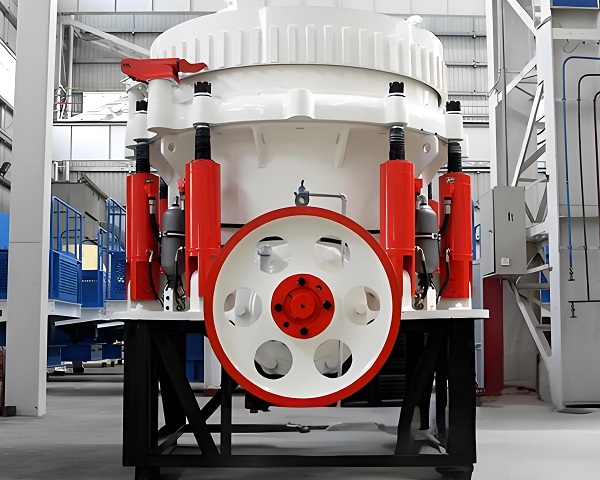

Product Picture Display of Multi-cylinder Cone Crusher

FAQ about Multi-cylinder Cone Crusher

>1. What is the working principle of a multi-cylinder cone crusher?

The multi-cylinder cone crusher drives the eccentric sleeve to rotate through a motor, driving the moving cone to perform a compound swing motion, and cooperates with 6-8 groups of hydraulic cylinders to achieve laminated crushing. The material undergoes the triple effects of extrusion, grinding and impact in the crushing chamber. The hydraulic system simultaneously completes the discharge port adjustment (accuracy ±0.5mm) and overload protection (response time ≤0.08 seconds), and the crushing efficiency is 35% higher than that of traditional equipment.

>2. What are the main differences between multi-cylinder and single-cylinder models?

The core difference lies in the layout of the hydraulic system: the multi-cylinder adopts a distributed hydraulic cylinder group (6-8 groups), the crushing force is more evenly distributed, and the processing capacity can reach 1500t/h (single cylinder is usually ≤1000t/h); the vibration value of the multi-cylinder is controlled below 1.8mm/s, and the running stability is improved by 30%; but the structure is more complex, and the maintenance cost is 20-25% higher than that of the single cylinder.

>3. What materials is this equipment suitable for processing?

Designed for high-hardness materials (compressive strength ≤ 400MPa), including natural ores such as granite and iron ore, and industrial waste such as steel slag. By changing the cavity type, it can process wet materials with a mud content of ≤8%, and the discharge particle size is adjustable from 3 to 50mm, which is particularly suitable for the production of high-grade aggregates (cubic content ≥ 92%).

>4. What are the technical highlights of the hydraulic system?

It adopts multi-cylinder pressure balancing technology (pressure deviation ±5%), integrated discharge adjustment, overload protection and cavity clearing functions; the working pressure is adjustable from 6 to 14MPa, and equipped with accumulator voltage stabilization; the intelligent diagnosis system can monitor the status of each group of hydraulic cylinders in real time, and the fault warning accuracy is ≥ 98%.

>5. What functions does the intelligent control system have?

Industrial-grade PLC control systems (such as S7-1500) collect 16 parameters in real time, including: ① hydraulic pressure (sampling frequency 200Hz) ② spindle position ③ vibration spectrum; support remote operation and maintenance, adaptive adjustment (automatic optimization of discharge port and feeding speed) and three-level fault protection (from warning to shutdown as fast as 0.5 seconds).

>6. How is the energy consumption performance of the equipment?

The power consumption per ton of crushing is 0.6-1.0kWh, which is 25-30% energy-saving than traditional equipment. The annual power saving of a production line with an output of 800 tons per hour is about 640,000 degrees, and the standby power consumption is <8kW. Energy-saving key points: ① variable frequency speed motor ② laminated crushing principle ③ intelligent load matching technology.

>7. What are the life and maintenance points of wear-resistant parts?

The life of ultra-high manganese steel liner (Cr22-Cr26) is 500-1500 hours, and the test data of nano-composite liner is up to 2000 hours. Maintenance focus: ① Replace hydraulic oil every 2000 hours ② Check the lubrication system (28 lubrication points) every day ③ Detect liner wear every 500 hours (RFID monitoring is optional).

>8. What are the typical application scenarios?

Three major mainstream applications: ① Large-scale mining crushing (providing ≤25mm feed for ball mills) ② High-end aggregate production (5-31.5mm fine aggregate) ③ Special building materials processing (such as cement clinker crushing). Projects with an output of more than 500 tons per hour have the best cost performance.

>9. How to ensure environmental protection performance?

Through three measures: ① Frame vibration isolation + silencer (noise ≤72dB) ② Fully enclosed structure + negative pressure dust removal (dust ≤15mg/m³) ③ Hydraulic system leakage protection (in line with ISO 4406 cleanliness standards), meet the latest environmental protection requirements.

>10. Future technology development direction?

Key breakthroughs: ① Digital twin technology (realizing virtual debugging) ② Predictive maintenance (fault prediction based on AI) ③ Application of new materials (such as tungsten carbide composite linings), with the goal of further increasing the overall efficiency of the equipment by 20%.