A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

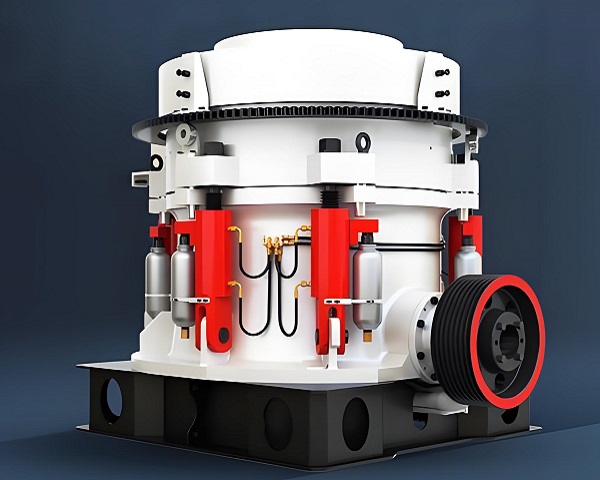

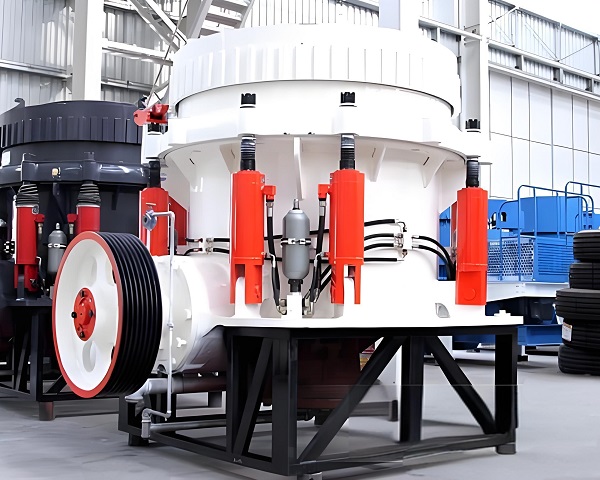

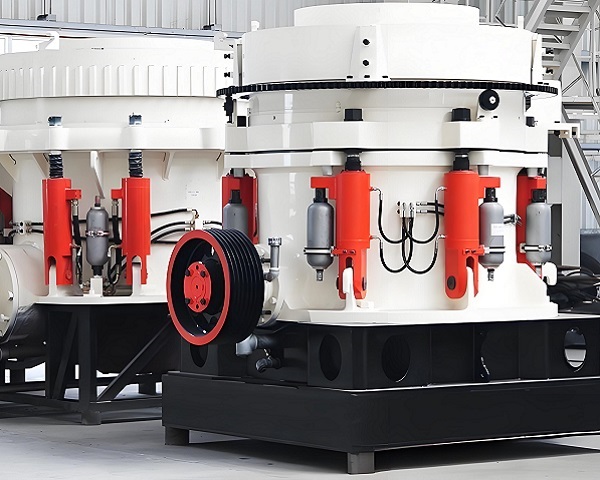

What is the Hydraulic Cone Crusher

Hydraulic cone crusher is one of the core equipment of modern crushing production line. It adopts advanced hydraulic technology and intelligent control system to realize efficient, precise and automated crushing operation. This equipment has made revolutionary innovation on the basis of traditional spring cone crusher. It replaces mechanical spring device with hydraulic system, which greatly improves the operation convenience and operation reliability of the equipment.

In terms of working principle, hydraulic cone crusher drives the eccentric sleeve to rotate through hydraulic motor, drives the moving cone to do pendulum motion, so that the material is subjected to multi-directional extrusion and grinding in the crushing chamber. Its unique lamination crushing principle ensures that the cubic proportion of the discharged particles is as high as more than 85%, which significantly improves the construction value of the finished aggregate. The hydraulic system not only provides power support, but also realizes real-time stepless adjustment of the discharge port. The adjustment range is usually 3-60mm, which fully meets the particle size requirements of different working conditions.

In terms of equipment structure, hydraulic cone crusher is mainly composed of key components such as frame, transmission device, eccentric sleeve assembly, hydraulic system, intelligent control system, etc. The hydraulic system includes hydraulic adjustment mechanism, hydraulic locking mechanism and hydraulic overload protection device. The coordinated work of these three ensures the stability and safety of equipment operation. When encountering unbreakable objects, the hydraulic system can respond quickly and complete unloading protection within milliseconds, minimizing the risk of equipment damage.

In terms of performance characteristics, hydraulic cone crusher has four significant advantages: first, high crushing efficiency, with a 15-30% increase in production capacity compared with spring type at the same power; second, high degree of automation, which can realize remote monitoring and intelligent adjustment; third, convenient maintenance, hydraulic cavity clearing function shortens maintenance time by more than 50%; fourth, low energy consumption, and the power consumption per ton of crushing is 20-25% lower than that of traditional equipment. These advantages make it widely used in large-scale sand and gravel aggregate production lines and mineral processing plants.

In terms of application areas, the equipment is particularly suitable for processing high-hardness materials such as granite, basalt, iron ore, etc., with a compressive strength of more than 350MPa. In the sand and gravel industry, it is mainly used for secondary or tertiary crushing; in the field of mineral processing, it is often used as pre-grinding fine crushing equipment. With the development of intelligence, the new generation of hydraulic cone crushers have begun to be equipped with Internet of Things systems, which can realize fault warning and remote diagnosis, representing the future development direction of crushing equipment.

In terms of maintenance, hydraulic cone crushers need to regularly check the quality of hydraulic oil and oil circuit sealing, and replace wear parts in time. Under normal maintenance conditions, the service life of the equipment can reach 8-10 years, and the replacement cycle of major wearing parts (such as linings) is between 400-600 working hours. A reasonable maintenance plan can ensure that the equipment always maintains the best working condition.

Market application shows that hydraulic cone crushers have become the standard configuration of modern stone production lines, especially in large-scale projects requiring high automation and strict environmental protection standards. Although the initial investment cost is high, its long-term economic and stability make its return on investment significantly better than traditional equipment. With the advancement of relevant policies, hydraulic cone crushers are continuing to develop in a smarter, more efficient and more environmentally friendly direction.

Operating principle of Hydraulic Cone Crusher

Hydraulic cone crusher is one of the core equipment of modern crushing production line. It adopts advanced hydraulic technology and intelligent control system to realize efficient, precise and automated crushing operation. This equipment has made revolutionary innovation on the basis of traditional spring cone crusher. It replaces mechanical spring device with hydraulic system, which greatly improves the operation convenience and operation reliability of the equipment.

In terms of working principle, hydraulic cone crusher drives the eccentric sleeve to rotate through hydraulic motor, drives the moving cone to do pendulum motion, so that the material is subjected to multi-directional extrusion and grinding in the crushing chamber. Its unique lamination crushing principle ensures that the cubic proportion of the discharged particles is as high as more than 85%, which significantly improves the construction value of the finished aggregate. The hydraulic system not only provides power support, but also realizes real-time stepless adjustment of the discharge port. The adjustment range is usually 3-60mm, which fully meets the particle size requirements of different working conditions.

In terms of equipment structure, hydraulic cone crusher is mainly composed of key components such as frame, transmission device, eccentric sleeve assembly, hydraulic system, intelligent control system, etc. The hydraulic system includes hydraulic adjustment mechanism, hydraulic locking mechanism and hydraulic overload protection device. The coordinated work of these three ensures the stability and safety of equipment operation. When encountering unbreakable objects, the hydraulic system can respond quickly and complete unloading protection within milliseconds, minimizing the risk of equipment damage.

In terms of performance characteristics, hydraulic cone crusher has four significant advantages: first, high crushing efficiency, with a 15-30% increase in production capacity compared with spring type at the same power; second, high degree of automation, which can realize remote monitoring and intelligent adjustment; third, convenient maintenance, hydraulic cavity clearing function shortens maintenance time by more than 50%; fourth, low energy consumption, and the power consumption per ton of crushing is 20-25% lower than that of traditional equipment. These advantages make it widely used in large-scale sand and gravel aggregate production lines and mineral processing plants.

In terms of application areas, the equipment is particularly suitable for processing high-hardness materials such as granite, basalt, iron ore, etc., with a compressive strength of more than 350MPa. In the sand and gravel industry, it is mainly used for secondary or tertiary crushing; in the field of mineral processing, it is often used as pre-grinding fine crushing equipment. With the development of intelligence, the new generation of hydraulic cone crushers have begun to be equipped with Internet of Things systems, which can realize fault warning and remote diagnosis, representing the future development direction of crushing equipment.

In terms of maintenance, hydraulic cone crushers need to regularly check the quality of hydraulic oil and oil circuit sealing, and replace wear parts in time. Under normal maintenance conditions, the service life of the equipment can reach 8-10 years, and the replacement cycle of major wearing parts (such as linings) is between 400-600 working hours. A reasonable maintenance plan can ensure that the equipment always maintains the best working condition.

Market application shows that hydraulic cone crushers have become the standard configuration of modern stone production lines, especially in large-scale projects requiring high automation and strict environmental protection standards. Although the initial investment cost is high, its long-term economic and stability make its return on investment significantly better than traditional equipment. With the advancement of relevant policies, hydraulic cone crushers are continuing to develop in a smarter, more efficient and more environmentally friendly direction.

Advantages and features of Hydraulic Cone Crusher

Comprehensive analysis of the advantages and characteristics of hydraulic cone crushers

Core technical advantages

1. Intelligent control system

The hydraulic cone crusher adopts advanced hydraulic and electronic control integrated technology to achieve real-time dynamic adjustment of the discharge port (accuracy ±1mm). With the automatic feeding control system, it can maintain the optimal crushing chamber filling rate, and the production capacity is increased by 25-35% compared with traditional equipment. The intelligent diagnosis system monitors multiple parameters such as vibration, temperature, and pressure to achieve fault prediction and protective shutdown.

2. Efficient laminated crushing

The optimized asymmetric crushing chamber combined with the precise moving cone motion trajectory realizes multi-layer composite crushing of materials, and the proportion of finished cubes reaches more than 90%. The special cavity design increases the fine material passing rate by 40%, while reducing the wear rate of the liner, and extending the service life of wear-resistant parts to 800-1200 hours.

Performance characteristics analysis

1. Hydraulic integrated system

(1) The three-in-one hydraulic station integrates adjustment, locking, and cavity clearing functions, and the operation response time is <0.5 seconds

(2) The overload protection sensitivity is 10 times that of the traditional spring type, and the pressure relief response time is <0.1 seconds

(3) The hydraulic cavity clearing function reduces the maintenance time by 70%, and a single cavity clearing operation takes <5 minutes

2. Modular design

(1) The upper frame has an integral hoisting structure, and the liner replacement time is <3 hours

(2) The two-way metal sealing system prevents dust from entering the transmission device

(3) The centralized lubrication system realizes automatic oiling of key parts, and the lubrication efficiency is increased by 50%

Application expansion

1. Multi-scenario adaptation

(1) By changing the cavity type, various materials with a compressive strength of 50-400MPa can be processed

(2) The special dustproof design is suitable for arid and dusty mining areas

(3) The low-temperature start function ensures normal operation in an environment of -25℃

2. Intelligent extension

(1) Support 5G remote monitoring and expert diagnosis system

(2) Can be connected to the factory DCS system to achieve fully automatic production

(3) Digital twin technology realizes real-time simulation of equipment status

Environmental protection and safety features

1. Adopt triple noise reduction design, working noise <75dB

2. Fully enclosed structure with negative pressure dust removal, dust emission <20mg/m³

3. Comply with CE certification and mine safety regulations

With its intelligent control, efficient crushing performance and excellent economy, this equipment has become the core equipment of modern sand and gravel aggregate production lines and ore dressing plants, especially suitable for large-scale projects with an annual output of more than 1 million tons. With the development of Industry 4.0 technology, the new generation of hydraulic cone crushers are continuously evolving towards predictive maintenance and adaptive control.

Technical Parameter Table of Hydraulic Cone Crusher

| Model | Cavity Type | Max Feed Size (mm) | Discharge Range (mm) | Capacity (t/h) | Motor Power (kW) | Weight (kg) |

|---|---|---|---|---|---|---|

| HST100 | C / M / F | 160 / 100 / 50 | 13–38 / 10–32 / 8–25 | 45–135 / 40–110 / 35–85 | 90 | 9200 |

| HST160 | C / M / F | 220 / 150 / 70 | 16–50 / 13–38 / 10–25 | 75–220 / 65–200 / 45–150 | 160 | 13000 |

| HST250 | C / M / F | 250 / 180 / 90 | 18–60 / 16–50 / 10–32 | 120–340 / 100–320 / 70–200 | 250 | 18000 |

| HST315 | C / M / F | 300 / 215 / 110 | 25–65 / 20–50 / 13–32 | 140–440 / 130–400 / 90–250 | 315 | 24000 |

| HPT200 | C / M / F | 185 / 150 / 95 | 16–38 / 13–32 / 10–25 | 90–250 / 72–200 / 55–180 | 160 | 13500 |

| HPT300 | C / M / F | 215 / 180 / 110 | 20–50 / 16–45 / 13–30 | 120–445 / 100–395 / 85–280 | 250 | 19000 |

| HPT400 | C / M / F | 240 / 200 / 135 | 25–65 / 20–55 / 16–35 | 150–630 / 120–550 / 90–360 | 315 | 26000 |

| HPT500 | C / M / F | 270 / 215 / 160 | 30–70 / 25–60 / 18–38 | 180–790 / 160–680 / 120–500 | 400 | 34500 |

If you have any special requirements, we will customize according to your special needs.

Product Picture Display of Hydraulic Cone Crusher

FAQ about Hydraulic Cone Crusher

>1. What is the working principle of the hydraulic cone crusher?

The hydraulic cone crusher uses a hydraulic system to drive the eccentric sleeve to rotate, drive the moving cone to do a swinging motion, so that the material is squeezed, ground and impacted in the crushing chamber. The hydraulic system simultaneously realizes the three functions of discharge port adjustment, overload protection and cavity cleaning. Through the PLC control system, intelligent operation is realized, and the crushing efficiency is increased by more than 30% compared with traditional equipment.

>2. What are the main structural components of the hydraulic cone crusher?

The main structure includes the frame, transmission device, eccentric sleeve assembly, hydraulic system (hydraulic cylinder, oil pump, control valve, etc.), intelligent control system and lubrication system. Among them, the hydraulic system is the core, responsible for equipment adjustment and protection; the intelligent control system can monitor the operating parameters in real time and automatically optimize the working state.

>3. What are the advantages of hydraulic cone crusher compared with spring cone crusher?

Hydraulic cone crusher has four significant advantages: the discharge port can be adjusted without stopping the machine, which is more convenient to operate; the overload protection response is faster (within 0.1 seconds); it is equipped with an intelligent control system and has a high degree of automation; the crushing efficiency is increased by 15-30%, and the energy consumption is reduced by more than 20%. It is particularly suitable for modern large-scale production lines.

>4. What materials are suitable for hydraulic cone crushers?

It is particularly suitable for crushing high-hardness materials (compressive strength ≤400MPa), such as granite, basalt, iron ore, etc., and can also be used for the recycling of construction waste. By changing different cavity types, the discharge particle size can be accurately adjusted within the range of 3-60mm to meet different production needs.

>5. What is the capacity range of hydraulic cone crusher?

The standard model has a capacity of 50-800 tons/hour. By adjusting the speed and discharge port, the maximum capacity can reach 1000 tons/hour. The specific output depends on factors such as material hardness, feed particle size and discharge requirements, and is usually about 20% higher than the same specification spring cone crusher.

>6. What are the maintenance points of hydraulic cone crusher?

Focus on the maintenance of hydraulic system (oil change every 2000 hours), lubrication system (automatic oil filling) and wear-resistant parts. It is recommended to conduct a comprehensive inspection every 500 hours, including the quality of hydraulic oil, wear of lining plate and status of transmission parts. Pay attention to the monitoring of parameters such as oil temperature and oil pressure on a daily basis.

>7. How is the energy consumption performance of hydraulic cone crusher?

The power consumption per ton of crushing is 0.6-0.9kWh, which is 20-30% energy-saving than traditional equipment. Taking the production line with an output of 300 tons per hour as an example, the annual operation of 8000 hours can save about 360,000 degrees of electricity, saving more than 250,000 yuan in electricity bills. Standby power consumption <5kW, no-load loss is reduced by 40%.

>8. What are the functions of the intelligent control system of hydraulic cone crusher?

Equipped with PLC control system, it has four intelligent functions: real-time monitoring of operating parameters such as oil pressure and temperature; automatic adjustment of discharge port and feeding speed; fault warning and protective shutdown; support remote monitoring and expert diagnosis. Some high-end models also support 5G networking and digital twin technology.

>9. How long is the service life of wear-resistant parts of hydraulic cone crushers?

Using high-chromium alloy steel liners, the service life under normal working conditions is 400-1200 hours. By optimizing the cavity design, controlling the feed particle size and uniform feeding, the service life can be extended by more than 30%. The liner replacement time is about 2-3 hours, saving 50% maintenance time compared with traditional equipment.

>10. What is the future development trend of hydraulic cone crushers?

Mainly develop in three directions: higher intelligence (AI control, predictive maintenance); more efficient and energy-saving (new cavity design, energy recovery); more environmentally friendly (noise <75dB, dust <20mg/m³). At the same time, it develops towards modular design to facilitate transportation, installation and maintenance.