A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

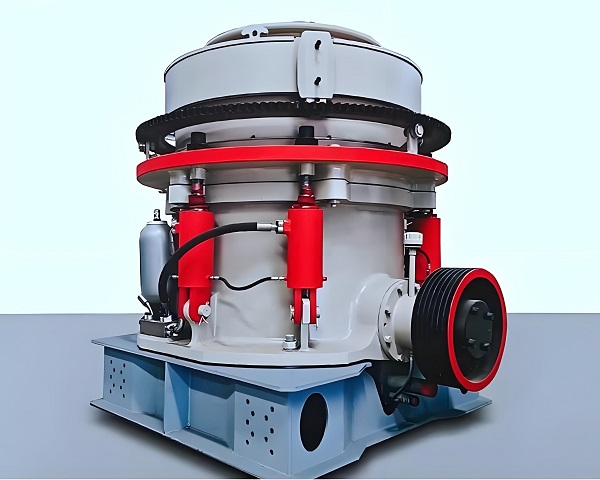

What is the Cone Crusher for Sale

Cone crusher is a key equipment for fine crushing of ores and rocks. With its unique structural design and working principle, it plays an irreplaceable role in many industrial fields.

In terms of working principle, cone crusher achieves crushing by swinging the moving cone around the eccentric sleeve. When the moving cone is close to the fixed cone, the material between the two is crushed by extrusion, bending and splitting; when the moving cone is far away, the material that meets the particle size requirements is discharged under the action of gravity, and the material that does not meet the standard continues to be crushed, and the cycle continues until the particle size standard is met.

Cone crushers are rich in types to meet different crushing needs. The standard type focuses on medium crushing with a moderate crushing ratio; the short head type focuses on fine crushing, and the finished product has a finer particle size; the compound type can flexibly switch between medium and fine crushing functions by adjusting the crushing chamber type, and the application scenarios are more extensive.

The performance advantages of this equipment are significant. First, it is applicable to a wide range of materials, especially good at processing medium and high hardness materials such as granite, basalt, and iron ore; second, it has high production efficiency. The output of large cone crushers can reach thousands of tons/hour, and the lamination crushing principle reduces energy consumption and increases production capacity; third, the particle size of the finished product is controllable. By adjusting the discharge port size, eccentricity and other parameters, the particle size and gradation of the finished product can be accurately controlled; fourth, it is easy to maintain. The modular design facilitates the replacement of wearing parts, and the intelligent monitoring system can warn of faults in real time, reducing maintenance costs and downtime risks.

The application scenarios of cone crushers cover mining, metallurgy, building materials, transportation infrastructure and other industries. It is used for ore crushing pretreatment in the mining field; processing raw materials in the metallurgical industry; producing stone in the building materials industry; providing high-quality aggregates for projects in highways, railways, and water conservancy projects.

In the future, cone crushers will develop in the direction of intelligence, large-scale and green. Rely on the Internet of Things and big data technology to achieve remote monitoring and intelligent control; develop larger-specification equipment to meet large-scale production needs; optimize structural design, adopt new wear-resistant materials, reduce energy consumption and noise, and promote green and sustainable development of the industry.

Operating principle of Cone Crusher for Sale

The cone crusher achieves medium and fine crushing of medium and high hardness materials with its unique mechanical structure and mechanical design. Its working principle is based on the relative movement of the moving cone and the fixed cone, and the materials are crushed by extrusion, bending and splitting.

From the perspective of equipment structure, the cone crusher is mainly composed of a frame, a fixed cone (outer cone), a moving cone (inner cone), an eccentric sleeve, a transmission device and other components. The fixed cone is fixed on the frame to form a fixed crushing wall; the moving cone is installed on the eccentric sleeve and performs periodic swinging motion driven by the transmission device. The motor transmits power to the eccentric sleeve through the pulley and the transmission shaft, driving the moving cone to rotate eccentrically around the center line of the crusher.

In the crushing chamber, the movement trajectory of the moving cone is the key to achieving crushing. Driven by the eccentric sleeve, the moving cone performs continuous eccentric swinging motion with the center line of the crusher as the axis. When the moving cone approaches the fixed cone, the space between the two gradually decreases, and the material entering the crushing chamber is subjected to strong extrusion, bending and splitting forces. Since the material is in a multi-layer stacking state in the crushing chamber, this laminated crushing method squeezes the material particles against each other, which not only has high crushing efficiency, but also effectively improves the particle size of the finished product.

The crushing process of the material is cyclical. After the large piece of material enters the crushing chamber from the feed port, it is first squeezed and crushed by the moving cone and the fixed cone in the upper part of the crushing chamber. With the swinging motion of the moving cone, the material gradually moves to the lower part of the crushing chamber, and is constantly squeezed and ground more strongly in the process. When the moving cone is away from the fixed cone, the space in the crushing chamber increases, and the material that has been crushed to meet the particle size requirements is discharged from the discharge port under the action of gravity; the material that does not meet the particle size standard continues to stay in the crushing chamber, waiting to be squeezed and crushed again when the next round of moving cone approaches, until the particle size meets the requirements.

The particle size of the finished material can be controlled by adjusting the size of the discharge port. The smaller the gap of the discharge port, the greater the number and intensity of squeezing the material in the crushing chamber, and the finer the particle size of the finished product. Some cone crushers can also adjust the discharge port size in real time through the hydraulic adjustment system, flexibly adapting to different production needs and ensuring efficient and stable crushing operations.

Advantages and features of Cone Crusher for Sale

As the core equipment for fine crushing of ores and stones, cone crushers are widely used in mining, metallurgy, building materials and other industries with their excellent performance advantages and distinctive characteristics, and have become key equipment in modern crushing technology.

Efficient crushing and high-quality finished products are the core competitiveness of cone crushers. It adopts the principle of lamination crushing, which makes the materials squeeze and crush each other in the crushing chamber. Compared with the traditional crushing method, it not only improves the crushing efficiency, but also produces finished products with uniform particle size and low needle-like content, and the grading is more in line with the engineering sand standard. This feature makes it very popular in the production of concrete aggregates and road base stones, effectively improving the quality and performance of building materials.

Strong material adaptability and a wide range of applications are the outstanding advantages of cone crushers. The equipment can handle materials with a hardness of up to Mohs hardness 9, such as granite, basalt, iron ore, etc., and is also suitable for medium-hardness ores such as limestone and dolomite. Whether it is the post-processing of coarse crushing in mining, the fine crushing link in building materials production, or the pretreatment of raw materials in the metallurgical industry, cone crushers can flexibly meet diverse crushing needs with different chamber types and specifications.

Energy saving and consumption reduction and low maintenance cost are the remarkable features of cone crushers. The optimized structural design and transmission system, combined with the principle of laminated crushing, reduce the ineffective friction loss, and reduce the energy consumption by 15%-30% compared with the same type of equipment. The key components of the equipment are made of highly wear-resistant materials, such as the crushing wall and the mortar wall, with a long service life; the modular design facilitates the rapid replacement of wearing parts and reduces downtime; the intelligent monitoring system monitors the operating status of the equipment in real time, warns of faults in advance, and further reduces maintenance costs and sudden losses.

Convenient operation and high degree of intelligence give cone crushers unique value. Some models are equipped with a hydraulic adjustment system, which can adjust the discharge port size with one button and accurately control the particle size of the finished product; the remote monitoring function enables operators to grasp the equipment operating parameters in real time through the Internet of Things platform, and perform remote operation and fault diagnosis. In addition, the equipment operates stably, with low vibration and low noise, effectively improving the working environment and meeting the requirements of green production.

With the development of technology, cone crushers are constantly upgraded and will continue to make breakthroughs in large-scale, intelligent and green directions in the future, further consolidating their leading position in the field of crushing equipment and providing more efficient and reliable crushing solutions for various industries.

Technical Parameter Table of Cone Crusher for Sale

| Item | Unit | PYB900 | PYB1200 | PYB1750 | PYB2200 |

|---|---|---|---|---|---|

| Max Feeding Size | mm | 115 | 145 | 215 | 300 |

| Discharge Opening Adjustment Range | mm | 15–50 | 20–50 | 25–60 | 30–60 |

| Capacity | t/h | 50–90 | 110–168 | 180–360 | 420–700 |

| Main Shaft Speed | r/min | 500 | 485 | 280 | 220 |

| Motor Power | kW | 55 | 110 | 160 | 280 |

| Overall Dimensions (L×W×H) | mm | 1990×1640×2380 | 2656×1950×2844 | 3910×2894×3809 | 4622×3302×4470 |

| Weight | t | 10.2 | 25.3 | 50.3 | 80.5 |

| Applicable Materials | - | Medium and hard ores | Medium and hard ores | Medium and hard ores | Medium and hard ores |

If you have any special requirements, we will customize according to your special needs.

Product Picture Display of Cone Crusher for Sale

FAQ about Cone Crusher for Sale

>What is a cone crusher?

A cone crusher is a medium and fine crushing equipment, mainly used to process ores and rocks of medium hardness or above. It squeezes, bends and splits the materials entering the crushing chamber through the relative movement between the moving cone and the fixed cone, and is widely used in mining, metallurgy, building materials and other industries.

>What types of cone crushers are there?

Mainly divided into standard type, short head type and compound type. The standard cone crusher is suitable for medium crushing, with a relatively small crushing ratio; the short head type is often used for fine crushing, and the finished product has a finer particle size; the compound cone crusher has the advantages of both, and can flexibly achieve medium or fine crushing operations by adjusting the crushing chamber type.

>What is the working principle of a cone crusher?

The moving cone of the cone crusher performs a swiveling motion driven by the eccentric shaft sleeve. When the moving cone approaches the fixed cone, the material is crushed by squeezing, bending and splitting between the two cones; when the moving cone moves away from the fixed cone, the material that has been crushed to meet the particle size requirements is discharged under the action of gravity, and the material that does not meet the standard continues to remain in the crushing chamber for the next round of crushing.

>What materials are suitable for cone crushers?

It is suitable for processing materials with higher hardness such as granite, basalt, quartz, iron ore, copper ore, and can also be used to process stones such as river pebbles. Its wear-resistant component design and strong crushing force can effectively meet the crushing needs of hard materials.

>What is the output of the cone crusher?

The output of the cone crusher varies depending on the model and specification. The output of small equipment can reach tens of tons per hour, and the output of large equipment can reach hundreds of tons or even thousands of tons. The processing capacity of the equipment can be further improved by optimizing the crushing chamber structure and increasing the speed.

>What is the energy consumption of the cone crusher?

Compared with the same type of crushing equipment, the cone crusher has lower energy consumption. Its lamination crushing principle reduces ineffective friction loss. With the efficient transmission system and energy-saving motor, it can achieve high output while reducing energy consumption per unit output, making the operating cost more economical.

>Is the maintenance of cone crusher complicated?

The cone crusher adopts modular design, and key components such as crushing wall and mortar wall can be easily replaced. The equipment is also equipped with an intelligent monitoring system, which can monitor the bearing temperature, vibration and other parameters in real time, and warn of faults in advance. Daily maintenance is mainly based on regular inspection and lubrication, and the overall maintenance difficulty is moderate.

>How to control the particle size of the finished product produced by the cone crusher?

The particle size of the finished product is controlled by adjusting the size of the discharge port. The smaller the discharge port, the finer the particle size of the finished product. In addition, according to the material characteristics and production needs, cone crushers with different crushing chamber types can be selected, or parameters such as eccentricity and speed can be adjusted to accurately control the particle size of the finished product.

>In which industries are cone crushers used?

Cone crushers are widely used in ore crushing in the mining industry, raw material pretreatment in the metallurgical industry, stone production in the building materials industry, and aggregate processing in highways, railways, and water conservancy projects. They are important equipment for achieving fine crushing of materials.

>What is the future development trend of cone crushers?

In the future, cone crushers will develop in the direction of intelligence, large-scale and green. Intelligence is reflected in the integration of Internet of Things technology to achieve remote monitoring and fault diagnosis; large-scale meets large-scale production needs; greening reduces energy consumption and noise and reduces environmental pollution by optimizing structure and adopting new materials.