A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

What is the Hydraulic Baler

Hydraulic baler is a mechanical device that uses hydraulic system to generate strong pressure to compress loose materials into regular blocks. It is widely used in many industries. Its core working principle is based on Pascal's law. The mechanical energy of the motor is converted into hydraulic energy through the hydraulic pump. The high-pressure oil pushes the piston of the hydraulic cylinder, exerting huge pressure on the material in the compression chamber, and finally the strapping mechanism completes the packaging.

The equipment is mainly composed of five parts: hydraulic system, compression chamber, feeding device, strapping mechanism and control system. As the power core, the hydraulic system includes hydraulic pump, hydraulic cylinder, control valve and other components to provide stable and strong compression power; the compression chamber is the space for material molding, and its size and shape can be customized according to the different materials to be processed; the feeding device is responsible for transporting the material to the compression chamber, which can realize manual or automatic loading; the strapping mechanism uses steel wire, plastic belt and other materials to fix the compressed material; the control system realizes precise control of the equipment operation through PLC or touch screen to ensure the orderly progress of each link.

In practical applications, hydraulic balers have significant advantages. In the waste paper recycling industry, it can compress messy waste paper into compact paper blocks for easy transportation and recycling; in the field of plastic recycling, it can compress waste plastic products to reduce storage volume; in agriculture, it is used for straw packaging, which solves the problem of straw processing and facilitates its secondary use as feed or biomass fuel; in addition, in the textile and metal waste processing industries, hydraulic balers also play an important role. With the continuous advancement of technology, hydraulic balers are developing in the direction of automation, intelligence, and energy saving, further improving work efficiency, reducing energy consumption, and meeting the growing material processing needs of different industries.

Operating principle of Hydraulic Baler

The power core of the hydraulic baler is the hydraulic system, which is mainly composed of motors, hydraulic pumps, hydraulic cylinders, control valves and oil tanks. When the equipment is started, the motor starts to run and drives the hydraulic pump to work. As an energy conversion device, the hydraulic pump converts the mechanical energy of the motor into hydraulic energy, sucks hydraulic oil from the oil tank, and outputs it after pressurization.

The pressurized hydraulic oil is transported to the control valve through a pipeline. The control valve is responsible for adjusting the flow direction, pressure and flow of the hydraulic oil to ensure that the hydraulic oil can be accurately distributed to each hydraulic cylinder as needed. When compressing the material, the hydraulic oil enters the main hydraulic cylinder, pushing the piston forward and generating a strong thrust, which is transmitted to the push plate in the compression chamber through the piston rod.

The compression chamber is the key area for material compression molding. The materials to be compressed, such as waste paper, plastic, straw, etc., are sent into the compression chamber manually or by conveyor belts. As the push plate gradually moves forward driven by the hydraulic cylinder, the material is continuously squeezed in the closed compression chamber, and the volume is greatly reduced. During the compression process, according to the material characteristics and actual needs, the operator can adjust the pressure of the hydraulic system through the control valve to achieve the ideal compression effect.

When the material is compressed to the set size or the pressure reaches the preset value, the control system will issue a command, the hydraulic pump stops working, and the hydraulic cylinder piston stops moving. At this time, the strapping mechanism begins to work, automatically strapping and fixing the compressed material with strapping tape or wire to prevent the material from loosening. After the strapping is completed, the hydraulic system acts again, and the hydraulic cylinder piston is retracted through reverse control, the compression chamber door is opened, and the compressed material package is pushed out, completing a complete packaging process. During the whole process, the PLC control system monitors the operating status of the equipment in real time, coordinates the orderly operation of various components, and ensures the efficient and stable operation of the hydraulic baler.

Advantages and features of Hydraulic Baler

The hydraulic baler is centered around a powerful hydraulic system, which gives it unrivaled compression capabilities. The hydraulic pump converts mechanical energy into hydraulic energy, which can generate pressures of tens or even hundreds of tons, and can compress fluffy materials such as waste paper, plastic, and straw to one-tenth of their original volume, greatly improving the utilization rate of storage space and reducing transportation costs. The hydraulic transmission is stable, and compared with mechanical transmission, its compression process is smooth, which reduces vibration and noise during equipment operation and extends the service life of the equipment.

In terms of automation, the hydraulic baler performs well. Equipped with a PLC intelligent control system, it can realize full-process automation of material automatic transportation, precise compression, intelligent bundling, and finished product launch, reducing manual intervention, not only improving work efficiency, but also reducing labor costs and operating error rates. At the same time, the equipment is equipped with multiple safety protection devices such as photoelectric sensing and emergency braking. When personnel approach dangerous areas or equipment abnormalities occur, the protection mechanism can be immediately activated to ensure the safety of operators.

The hydraulic baler also has a wide range of applicability and good economy. Whether it is waste paper recycling, plastic processing, agricultural straw processing, metal waste compression and other fields, it can operate efficiently. Its modular design makes it easy to disassemble and replace each component, making daily maintenance and troubleshooting easier, effectively reducing downtime. In addition, the use of energy-saving hydraulic pumps and motors reduces the energy consumption of equipment operation, and combined with the reduction in transportation costs brought by the high compression ratio, it creates significant economic benefits for the company. With the continuous advancement of technology, hydraulic balers are also continuously upgraded in the direction of intelligence and environmental protection to meet more industry needs.

Technical Parameter Table of Hydraulic Baler

| Model | Compression Force (Tons) | Bale Size (mm) | Bale Weight (kg) | Motor Power (kW) | Operation Mode | Applicable Materials | Machine Size (mm) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|

| YD-6040T20 | 20 | 600×400×400 | 40–80 | 4 | Manual | Paper, film, fabric | 1600×1000×2000 | 900 |

| YD-8060T30 | 30 | 800×600×500 | 80–150 | 5.5 | Manual | Paper, textile, plastic bags | 1800×1100×2200 | 1200 |

| YD-10080T50 | 50 | 1000×800×600 | 150–250 | 7.5 | Semi-Automatic | Carton boxes, PET bottles | 2000×1200×2500 | 1800 |

| YD-120100T80 | 80 | 1200×1000×800 | 250–400 | 11 | Semi-Automatic | Plastic, old clothes, soft bulky materials | 2300×1300×2800 | 2500 |

If you have any special requirements, we will customize according to your special needs.

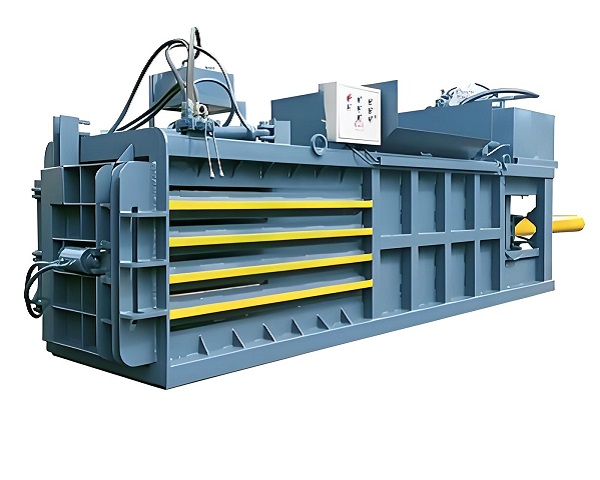

Product Picture Display of Hydraulic Baler

FAQ about Hydraulic Baler

>What are the main applications of hydraulic balers?

It is widely used in waste paper recycling, plastic processing, textiles and clothing, agricultural straw processing, metal waste compression and other fields. It can effectively compress various loose materials for easy storage and transportation.

>What types of hydraulic balers are there?

It is mainly divided into two types: vertical and horizontal. The vertical type occupies a small area and is easy to operate, suitable for small enterprises or scenes with small processing volume; the horizontal type has a large processing volume and a high compression ratio, and is often used for large-scale material processing.

>What is the compression ratio of the hydraulic baler?

The compression ratio varies depending on the material. Generally speaking, the compression ratio of lightweight materials such as waste paper and plastic can reach 1:5-1:10, and the compression ratio of materials with higher density such as metal waste can also reach 1:2-1:3.

>How to choose a suitable hydraulic baler?

Factors such as material type, processing volume, site size, and budget need to be considered. If the processing volume is large, choose horizontal type, and if the space is limited, choose vertical type; at the same time, pay attention to the pressure parameters, degree of automation and brand reputation of the equipment.

>What should be paid attention to in the daily maintenance of hydraulic balers?

Regularly check the quality and quantity of hydraulic oil, replace aging seals in time to prevent oil leakage; clean the residual materials in the compression chamber and conveyor belt; check whether the connections of various components are loose to ensure the normal operation of the equipment.

>What are the common faults of hydraulic balers?

Common faults include insufficient pressure in the hydraulic system, oil leakage in the hydraulic cylinder, and failure of the strapping mechanism. Insufficient pressure may be caused by hydraulic oil contamination or oil pump failure; oil leakage is mostly caused by seal wear; failure of the strapping mechanism may be mechanical jamming or sensor failure.

>Does the hydraulic baler have high energy consumption?

Its energy consumption is related to the equipment model, working frequency and compression pressure. Compared with traditional mechanical balers, hydraulic balers can reduce energy consumption while ensuring efficient work by optimizing the hydraulic system and energy-saving design.

>What is the degree of automation of hydraulic balers?

Modern hydraulic balers are equipped with PLC control systems, which can realize full-process automation operations such as automatic feeding, compression, strapping, and bagging, reduce manual intervention, and improve work efficiency and packaging accuracy.

>How long is the service life of a hydraulic baler?

Under normal use and maintenance, the service life of a hydraulic baler can reach 8-15 years. Good maintenance, such as regular oil changes and timely repair of faults, can extend the service life of the equipment.

>Can hydraulic balers handle wet materials?

Try to avoid handling materials that are too wet, because moisture may corrode the internal structure of the equipment, affect the performance of the hydraulic system, and reduce the compression effect and the quality of the bales, except for specially designed waterproof balers.

>What is the price range of hydraulic balers?

The price is affected by factors such as equipment type, specifications, brand, and degree of automation. The price of a small vertical hydraulic baler is tens of thousands of yuan, and the price of a large horizontal fully automatic hydraulic baler can reach hundreds of thousands of yuan.