A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

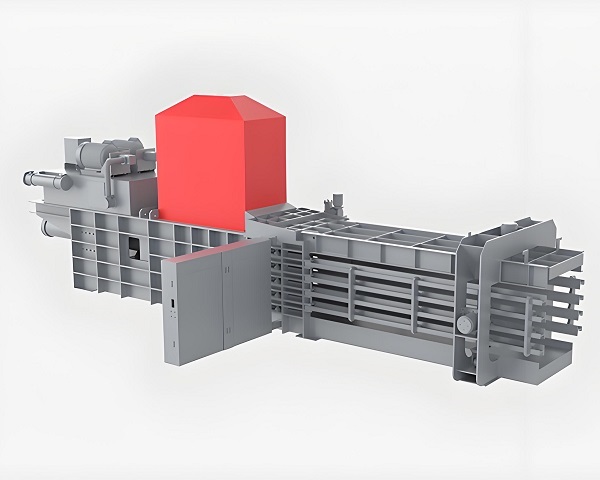

What is the Horizontal Balers

The horizontal baler compresses materials horizontally. Its structure mainly consists of a feeding device, a compression chamber, a hydraulic system, a strapping mechanism, and a control system. During operation, the material is fed into the compression chamber through a conveyor belt or manually, and then the hydraulic system drives the piston to compress the loose material into a compact block with strong pressure. After reaching the set size, the strapping mechanism automatically completes the strapping action to form a standard package that is easy to transport and store.

This equipment has significant advantages. In terms of processing capacity, the horizontal baler has a larger compression chamber, which can accommodate more materials at a time. It is suitable for processing large quantities of loose materials such as waste paper, plastics, and straw, and can process several tons per hour; the compression ratio is high, which can greatly reduce the volume of the material, save more than 80% of the storage space, and effectively reduce the storage and transportation costs. It has a high degree of automation, and can realize one-button operation of the feeding, compression, strapping and other processes through the PLC control system, reduce manual intervention, and improve work efficiency; and it is equipped with safety protection devices to ensure the safety of operators.

The horizontal baler is widely used. In the waste paper recycling industry, it can pack messy waste paper for centralized transportation and reprocessing; in the field of plastic recycling, it can compress discarded plastic products to reduce environmental pollution; in agriculture, it can be used to pack straw, which not only solves the problem of straw treatment, but also facilitates its secondary use as feed or biomass fuel; in the textile industry, it can also compress and pack scraps and waste fabrics to achieve rational use of resources. With the development of technology, horizontal balers are moving towards intelligence and energy saving, providing strong support for the green and sustainable development of various industries.

Operating principle of Horizontal Balers

After the horizontal baler is started, the feeding system will start to operate first. For different types of materials, manual delivery or automatic delivery can be used. For example, when processing waste paper, the conveyor belt will continuously feed the waste paper into the compression chamber; when processing agricultural materials such as straw, it can be placed manually at the feed port, and the material can be transported to the designated location with the help of a chain or a screw propeller.

After the material enters the compression chamber, the core compression link begins. The horizontal baler is equipped with a powerful hydraulic system, which uses a hydraulic pump as the power source. The motor drives the hydraulic pump to rotate, converts mechanical energy into hydraulic energy, and generates high pressure on the hydraulic oil. The high-pressure oil is transported to the hydraulic cylinder through the pipeline, pushing the piston to do horizontal reciprocating motion in the compression chamber. The piston squeezes the material with huge pressure. With repeated compression, the air in the material is discharged, the molecular distance is reduced, and the volume continues to decrease. In this process, the compression force and stroke can be accurately adjusted through the hydraulic valve and control system to meet the compression requirements of different materials.

When the material is compressed to the set size and density, it enters the bundling process. The bundling mechanism mostly uses automatic bundling technology, and common bundling methods include steel wire and plastic belt. The sensor detects that the material has reached a suitable state, triggering the strapping mechanism to wrap the strapping material around the bale and fix it by hot melting, snapping, etc. to ensure that the bale will not loosen during subsequent transportation and storage. Finally, the bale pushing device pushes the formed bale out of the compression chamber to complete a packaging cycle. After that, the equipment will automatically return to the initial state, wait for the next feeding, and continue the packaging work. The entire process is coordinated and monitored by the electrical control system to achieve efficient, stable and safe automatic operation.

Advantages and features of Horizontal Balers

From the perspective of structural design, the horizontal baler adopts horizontal compression and is equipped with a large-size compression chamber. Compared with the vertical baler, it can accommodate more materials and can handle up to several tons of materials at a time. It is especially suitable for handling large and large quantities of loose materials. Its hydraulic system is the core power source, with strong and stable pressure. It can flexibly adjust the compression force according to the characteristics of the material, achieve a compression ratio of up to 1:10, and compress the fluffy materials into compact blocks, greatly saving storage space and transportation costs.

Automation and intelligence are the outstanding advantages of horizontal balers. The advanced PLC control system can realize the full-process integrated operation of automatic feeding, precise compression, and intelligent bundling without too much manual intervention. While reducing labor costs, it can also avoid manual operation errors and improve packaging quality and efficiency. At the same time, the equipment is also equipped with multiple safety protection devices, such as photoelectric sensors, emergency brake buttons, etc., which automatically warn or shut down when people approach dangerous areas, effectively ensuring the safety of operators.

The horizontal baler has a wide range of applications and has good versatility and flexibility. Whether it is waste paper, plastic, textiles and other recycling industry waste treatment, or straw, forage baling in the agricultural field, or industrial scrap compression, it can do it. In addition, it has low energy consumption, uses energy-saving hydraulic pumps and motors, and can reduce energy consumption by 20% - 30% during operation compared to traditional baling equipment, reducing corporate operating costs. The horizontal baler is also easy to maintain. The modular design makes it easy to disassemble and assemble each component, making daily maintenance and troubleshooting easier, reducing downtime and ensuring efficient operation of the equipment.

Technical Parameter Table of Horizontal Balers

| Model | Compression Force (Ton) | Bale Size (mm) | Feeding Opening Size (mm) | Bale Weight (kg) | Output (Bales/hour) | Motor Power (kW) | Tying Method | Control System | Applicable Materials | Machine Size (mm) | Machine Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| HB-8060T30 | 30 | 800×600×500 | 900×600 | 80–150 | 2–4 | 7.5 | Manual, 4 Steel Wires | Manual Button / PLC | Waste paper, film, fabric | 3000×1800×1600 | 3000 |

| HB-10080T60 | 60 | 1000×800×600 | 1100×800 | 150–300 | 3–6 | 15 | Automatic, 5 Steel Wires | PLC + Touch Screen | Waste paper, plastic, textile | 4500×2200×2000 | 5000 |

| HB-12080T80 | 80 | 1200×800×700 | 1300×800 | 200–400 | 4–7 | 22 | Automatic, 5 Steel Wires | PLC + Touch Screen | Bottles, cardboard, film | 5000×2400×2200 | 7000 |

| HB-15090T100 | 100 | 1500×900×750 | 1600×900 | 300–600 | 5–8 | 30 | Automatic, 5 Steel Wires | PLC + Touch Screen | PET bottles, bulky soft material | 6000×2600×2400 | 9500 |

| HB-180100T120 | 120 | 1800×1000×800 | 1900×1000 | 400–800 | 6–10 | 37 | Automatic, 5 Steel Wires | PLC + Touch Screen | High-density materials | 7000×2800×2600 | 12000 |

If you have any special requirements, we will customize according to your special needs.

Product Picture Display of Horizontal Balers

FAQ about Horizontal Balers

>Which industries are horizontal balers suitable for?

It is widely used in waste paper recycling, plastic processing, agricultural straw processing, textile waste recycling, metal scrap compression, and food industry packaging, and can handle all kinds of loose materials.

>What is the difference between horizontal balers and vertical balers?

The compression chamber of the horizontal baler is placed horizontally, with a large single processing volume and a high compression ratio, which is suitable for large-scale production; the vertical baler is placed vertically, with a small footprint, suitable for small enterprises and scenes with small processing volume. Both have their own characteristics in structure, processing capacity and applicable scenes.

>What is the maximum compression force of the horizontal baler?

Different models of horizontal balers have different maximum compression forces. Generally, the compression force of small equipment is 10-30 tons, that of medium-sized equipment is 30-100 tons, and that of large industrial-grade equipment can reach more than 100 tons. You can choose the appropriate model according to actual needs.

>How to perform daily maintenance on the horizontal baler?

It is necessary to regularly check the oil level and quality of the hydraulic oil, replace aging or damaged seals in time, clean the equipment surface and compression chamber, check the wear of the strapping mechanism, ensure that the components are tightly connected, and regularly lubricate and maintain the moving parts.

> Does the horizontal baler have high energy consumption?

The energy consumption of the horizontal baler with energy-saving hydraulic system and motor is relatively reasonable. Compared with traditional equipment, it can reduce energy consumption by 20% - 30% through optimized design, and the efficient compression work can reduce the energy consumption of material transportation, and the comprehensive energy saving effect is significant.

> Can the horizontal baler handle wet materials?

Some horizontal balers are specially designed to handle materials with a certain humidity, but wet materials may affect the compression effect and the service life of the equipment. It is generally recommended to handle dry materials as much as possible. If you need to handle wet materials, you need to communicate with the manufacturer in advance to select an adapted model.

> What is the degree of automation of the horizontal baler?

Horizontal balers equipped with PLC control systems can realize the full process of feeding, compression, and bundling. They can also set parameters and monitor them through the touch screen. Some high-end models support remote fault diagnosis and data transmission, and have a high level of automation.

> Can the size of the bale of the horizontal baler be adjusted?

The size of the bale of most horizontal balers can be adjusted by adjusting the baffle inside the compression chamber or setting the control system parameters to meet the needs of different materials and transportation storage.

> What is the price range of horizontal balers?

The price of horizontal balers is affected by factors such as model, processing capacity, and degree of automation. The price of small and simple equipment is tens of thousands of yuan, and the price of medium and large fully automatic equipment can reach hundreds of thousands or even millions of yuan.

> Does the installation of horizontal balers require professionals?

Because it involves the connection and debugging of the hydraulic system and electrical system, it is recommended that the installation of horizontal balers be carried out by professional technicians of the manufacturer to ensure that the equipment is installed correctly and operates safely and stably.

> How to quickly troubleshoot a horizontal baler?

When a fault occurs, you can first check the fault code prompt on the equipment display screen, and preliminarily determine the cause of the fault in conjunction with the operation manual; check the hydraulic system pressure, circuit connection, operation of mechanical parts, etc. If the problem cannot be solved, you should promptly contact the manufacturer's after-sales personnel for professional maintenance.